Pull trigger after starting stroke. Release

trigger before end of stroke. Gun must be

moving when trigger is pulled and

TI2037A

Aiming Gun

Aim center of spray of gun at bottom edge

of previous stroke, overlapping each

stroke by half.

Spray Pattern Quality

A good spray pattern is evenly distributed

•

Spray should be atomized (evenly

dis- tributed, no gaps at edges).

If tails persist when spraying at the highest

•

Spray tip may be worn. See Tip

and Pressure Selection, page13.

•

A smaller spray tip may be needed.

•

Material may need to be thinned. If

material needs to be thinned follow

manufacturer’s recommendations.

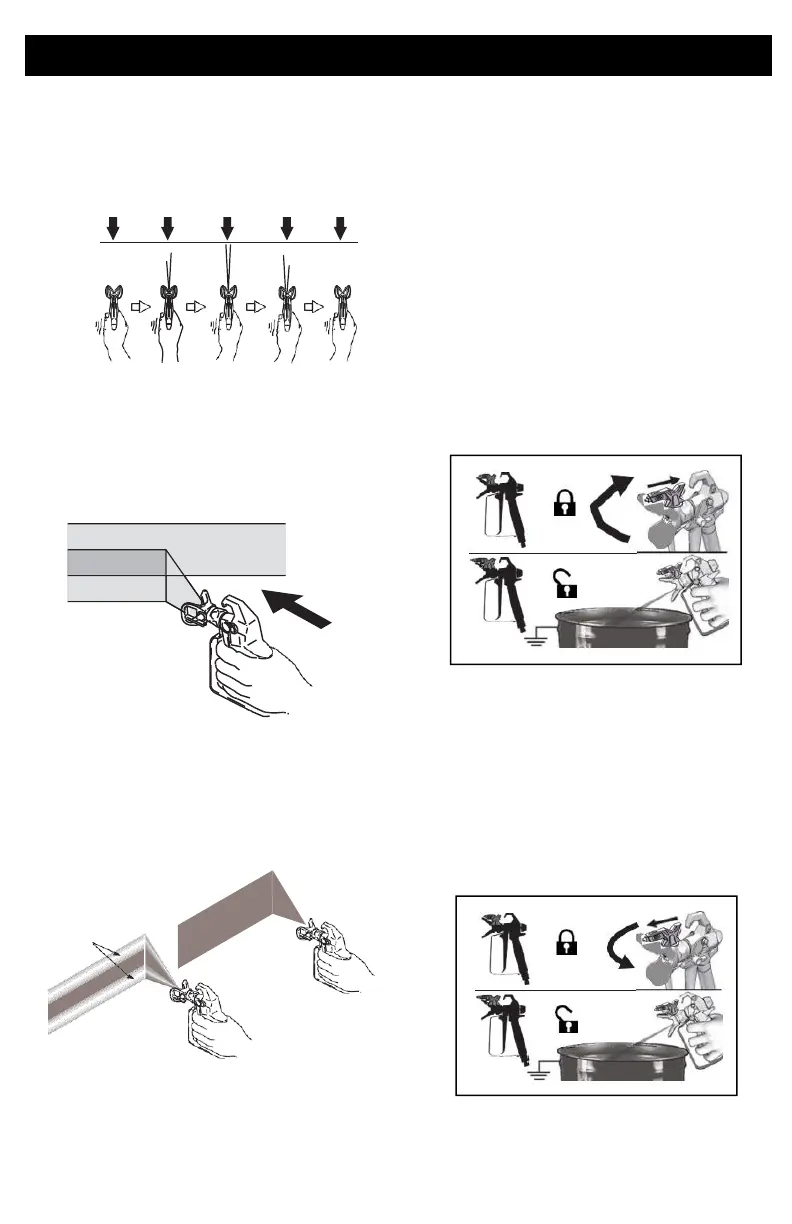

Clear Tip Clog

In the event that particles or debris clog the

airless spray gun tip, this airless sprayer is

designed with a reversible spray tip that

quickly and easily clears the particles without

disassembling the sprayer.

See Strain the Paint, page 8, for additional

1.

Engage trigger lock. Rotate spray tip to

unclog position. Disengage trigger lock.

Trigger gun at waste area to clear clog.

UNCLOG

NOTE: If spray tip is difficult to rotate when

turning to the unclog position perform,

Pressure Relief Procedure, page 9, then

turn Prime/Spray valve to spray position and

repeat step 1.

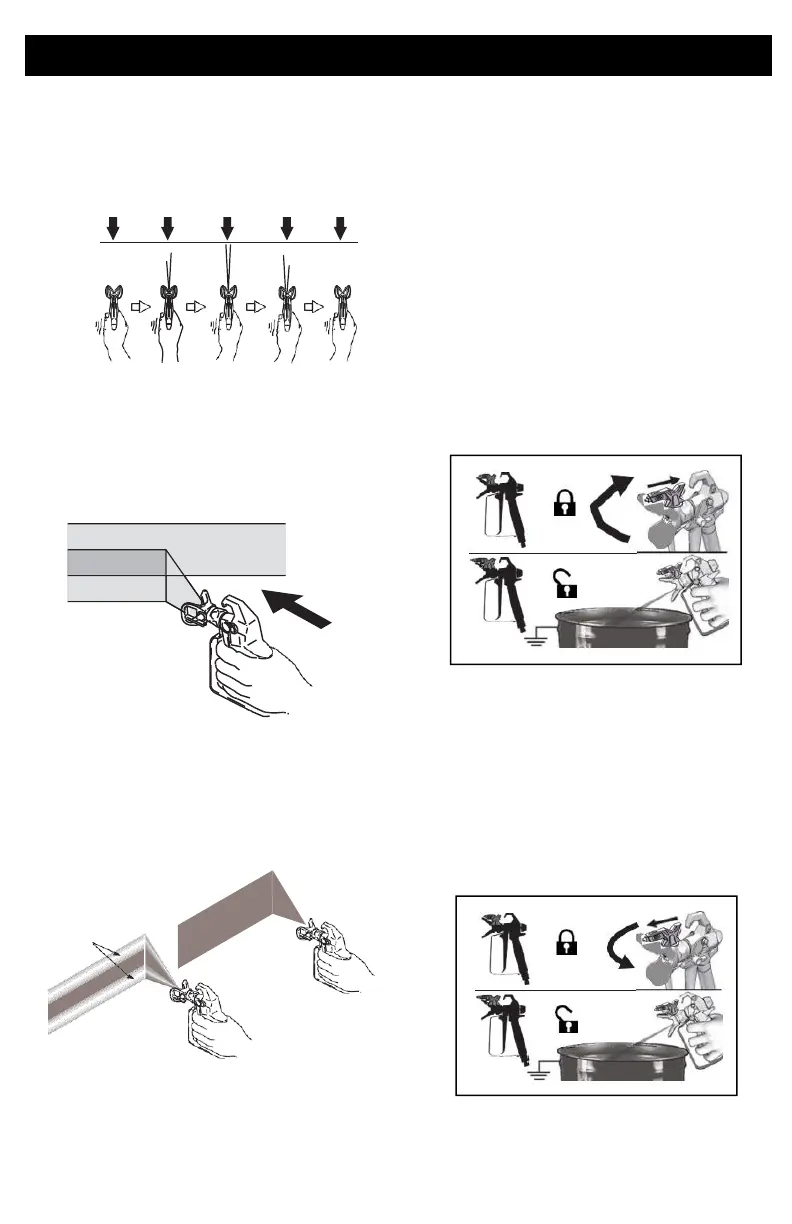

2.

Engage trigger lock. Rotate spray tip

back to spray position. Disengage trig-

ger lock and continue spraying.

SPRAY

Loading...

Loading...