Maintenance

Routine maintenance is important to ensure proper operation of your x3 airless sprayer.

Inspect motor shroud openings for blockage.

Daily or each time you spray

Inspect/clean filter, fluid inlet strainer, and gunfilter.

Daily or each time you spray

NOTICE

High Pressure Hoses

Check hose for damage every time you

spray. Do not attempt to repair hose if hose

jacket or fittings are damaged. Do not use

hoses shorter than 25 ft (7.6 m). Wrench

tighten, using two wrenches.

•

Always clean tips with compatible

cleaning fluid and brush after spraying.

•

Tips may require replacement after 15

gallons (57 liters) or they may last

through 60 gallons (227 liters) depend-

ing on abrasiveness of paint.

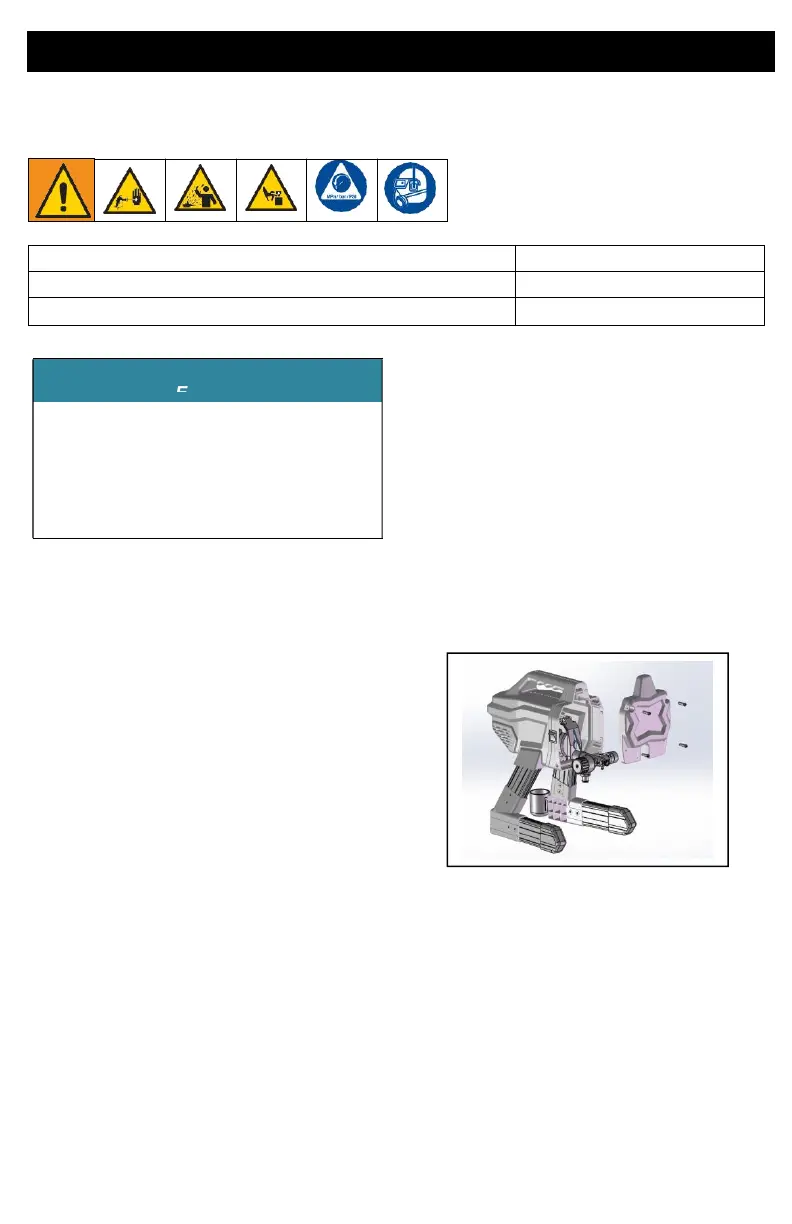

Remove high pressure hose, it may also be

necessary to remove the suction tube.

Always perform Pressure Relief Procedure,

page 9, before starting any pump repairs and

1.

Screw out the fixing screws and

taking down the front cover.

Protect the internal drive parts of this

sprayer from water. Openings in shroud

allow cooling of mechanical parts and

electronics inside. If water gets into these

openings, the sprayer could malfunction or

be permanently damaged.

Loading...

Loading...