Basics

Dräger X-dock 5300/6300/6600 15

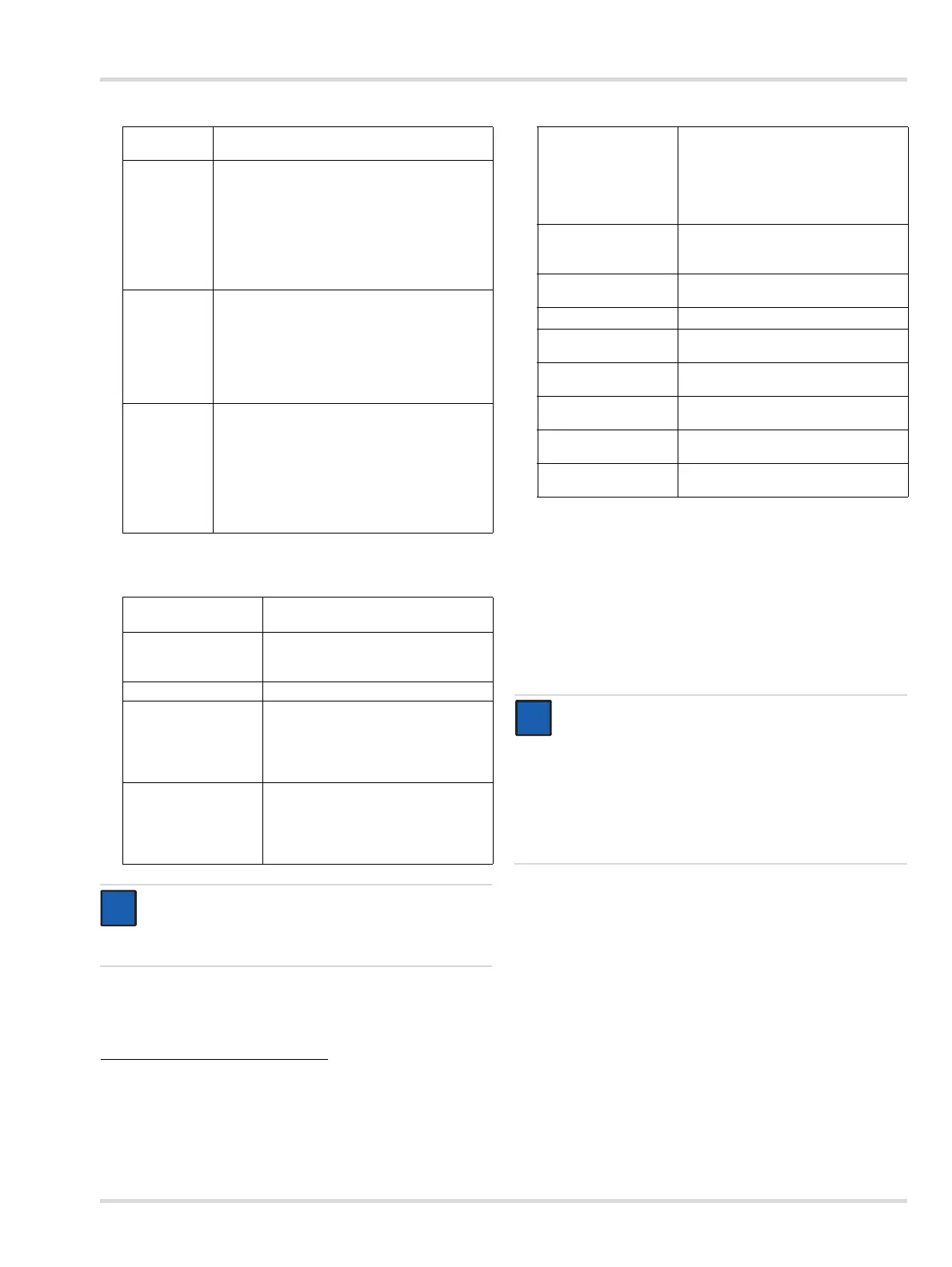

Tests with substitute gas

1

4. Assign the desired authorisation level.

5. Select Options if necessary.

The following options are available:

6. If required, select Further options:

7. Save settings with OK.

4.10 Set up template configuration

The maintenance station can configure gas monitors

automatically using a configuration template. The

configuration templates can be created using the Dräger CC-

Vision PC software. The configuration templates can be

transferred to the maintenance station using a USB memory

stick or the X-dock Manager.

1. Create a configuration template using the CC-Vision PC

software.

2. Transfer the template file to the station using a USB

memory stick or the X-dock Manager (see chapter 6.5.7 on

page 21 and online help for X-dock Manager).

3. When defining a test, select the desired option:

a. Select Check config. whether to carry out just one

check of the configuration.

-

No gas test, only the activated options are

run.

Schneller

Begasungst

est

For tests with substitute gas, a switch is

made to the test gas. So, for example, the

influence of temperature is reduced and a

greater accuracy is achieved.

Since the alarm thresholds no longer apply

here, it is always tested at a calculated

threshold. The threshold is calculated at 1/

3*test gas concentration.

Erweiterter

Begasungst

est

For tests with substitute gas, a switch is

made to the test gas. So, for example, the

influence of temperature is reduced and a

greater accuracy is achieved.

For the extended test, a check is carried out

on the test gas concentration with the set

tolerance.

Calibration

For calibration with substitute gas, a switch

is made to the test gas. So, for example, the

influence of temperature is reduced and a

greater accuracy is achieved.

Calibration uses the test gas concentration

of the test gas. Following successful

calibration, a switch is made to the

measured gas.

1 (The Pac 7000 OV PAC 7000 OV-A does not support switching to

the test gas. For this reason, the X-dock performs the conversion

here. There is no compensation for the effects of temperature, so

testing/calibration is only recommended in a range of from 0-

30 °C.)

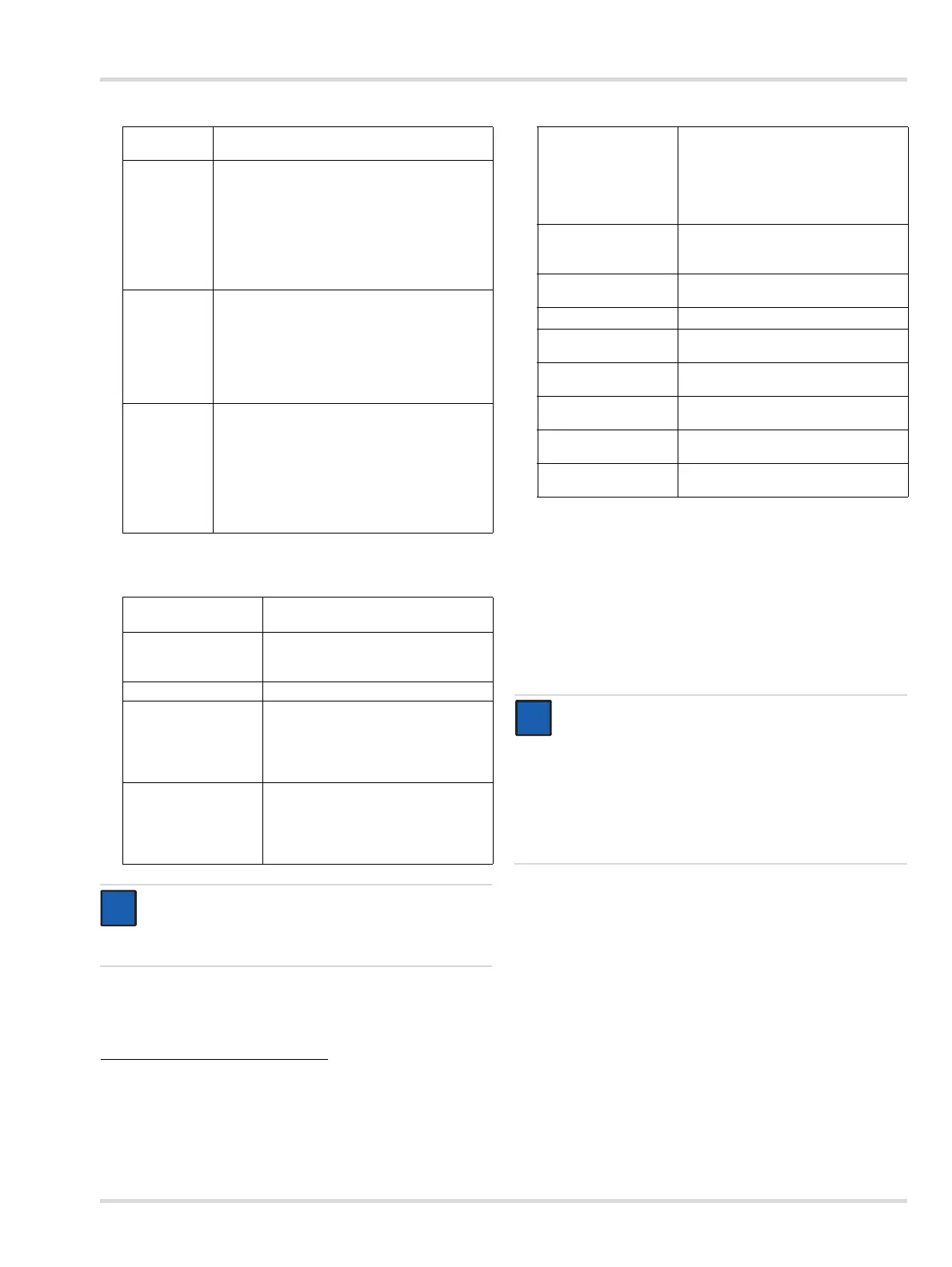

Response time test

(only for calibration)

The response times of the sensors

are tested.

Alarm test

All the alarm functions of the gas

monitor are checked (noise, light,

vibration if configured).

Zero check

The zero point is checked.

Check config.

The configuration of the gas monitor

is compared with the template

activated at the station. If the

configuration does not match, an

error message is generated.

Set config.

If this option is activated, the gas

monitors are configured according

to the activated template at the

station if a deviation has previously

been determined.

NOTICE

When the alarm functions are being tested, the

ambient noise must not be too loud as otherwise the

station will not be able to check the horn function.

Time sync.

The time on the gas monitor is

synchronised with the station.

If this option is selected, Reset DL

and Reset TWA are automatically

also activated to ensure that the DL

(data logger) is unique.

Download DL

Download data memory and events

memory data from the gas monitor

to the station.

Reset DL

The data in the data and events

memories are cleared.

Reset TWA

The TWA

1

time is reset.

1 Average shift values (time-weighted average) are generally

limited to eight hours exposure per day per workplace for

5 days a week during a work lifetime.

Turn off

The gas monitor is switched off

automatically after the test.

AutoCal

Perform automatic calibration (e. g.

calibrate after a faulty bump test).

Purge

The system is purged with fresh air

after every test.

Generate

2

2 In the case of networked systems, Dräger recommends that

you do not activate the “Generate” option but create the

certificate using the X-dock Manager. This reduces the test

duration.

Create certificate (stored in the

station as a PDF file).

Print

Print out the certificate on a

connected USB printer.

NOTICE

Before changing the configuration, Dräger

recommends:

1. Transferring the new configuration template to a

gas monitor using an X-dock station.

2. Checking the new configuration on the gas monitor

using the Dräger CC-Vision PC software,

3. approving the configuration template and

distributing it to the corresponding X-dock station.

i

i

Loading...

Loading...