IM02602002E

Page 2-2

wwweaton.com

MP-3000

The MP-3000 Motor Protection relay includes logic to control the num-

ber of starts that can occur on the motor in a given time period for cold

and hot motor conditions. Settable timers are provided to control the

time between starts and to restart a motor after a stop. Additional logic

is included for transition control of reduced-voltage starters.

Motors typically have limits on the number of cold starts, starts per time

period, and time between starts that are permitted without damage.

The MP-3000 incorporates these checks to prevent excessive starting

of the motor.

The MP-3000 provides transition and incomplete sequence detection

function for reduced voltage starting. The User can select to transi-

tion based on four logical combinations of starting current and time

sequence. The incomplete sequence function can be used indepen-

dently for feedback indication from the process, to trip the motor if

expected action does not occur.

For certain applications, such as pumping a uid up a pipe, the motor

may be driven backward for a period of time after it stops. The MP-

3000 provides an antibackspin timer (minimum time between stop and

restart) to prevent starting the motor while it is spinning in the reverse

direction. The relay displays the timer countdown from the moment a

stop is declared by the relay.

The MP-3000 provides a mechanical load shedding feature that can be

used to control the driven process. The load shedding function closes

a contact on an overload condition to stop addition of load until the

overload condition subsides by a set amount. Then the load shedding

contact opens and the load is restored.

The MP-3000 has a User-programmable feature that lets the operator

reset certain trip conditions, including the jogging timers and thermal-

model overload bucket. This function is for use in emergency condi-

tions only and may result in motor damage or failure. The override

action is logged with time-tag. The pushbutton is located behind a

security door. The function can be disabled.

Large motors with high inertia loads, such as centrifuges and large

fans, may experience starting currents that greatly exceed the full load

current for greater than the locked-rotor time. The MP-3000 has a tim-

ing feature that holds off thermal tripping during the long acceleration.

This should be used this with a zero-speed switch input.

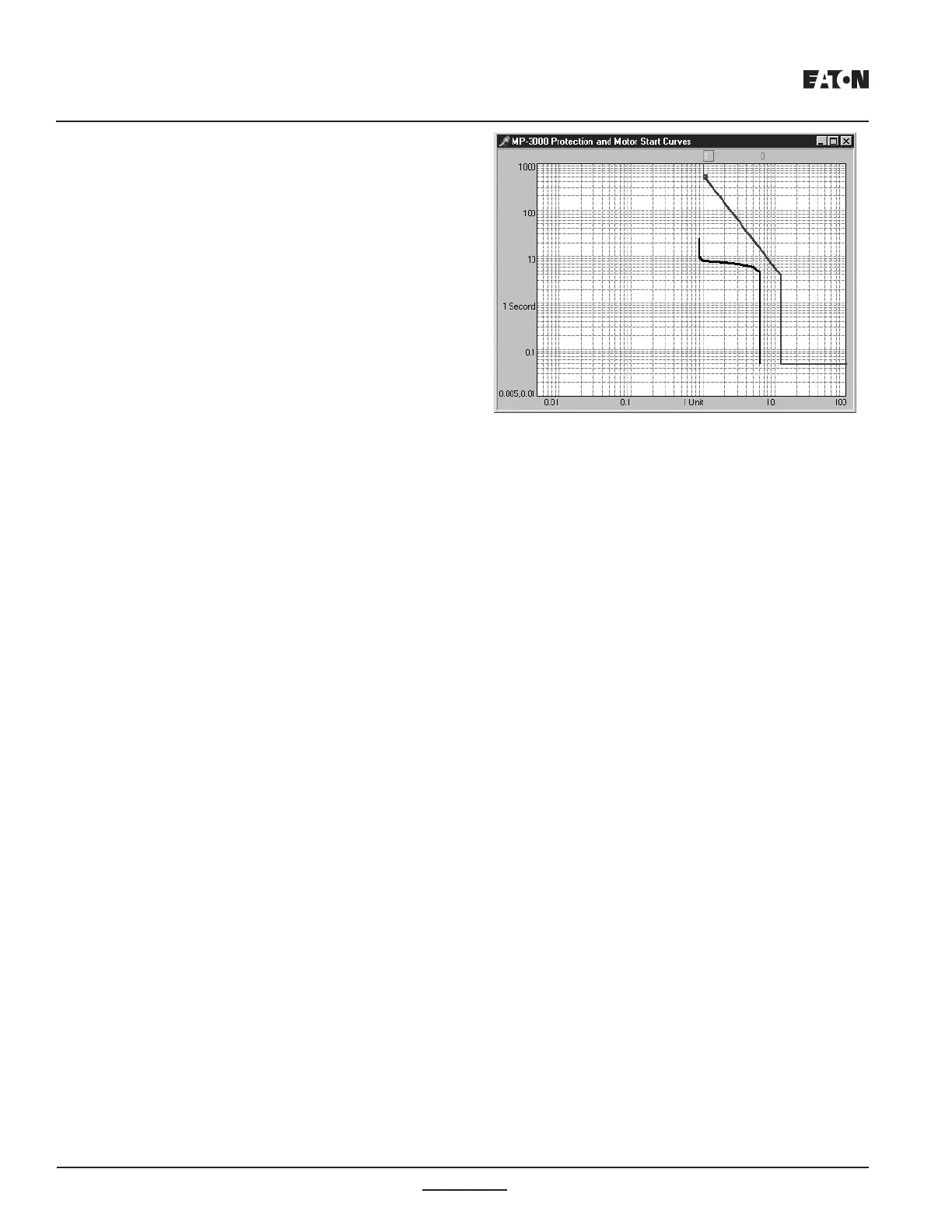

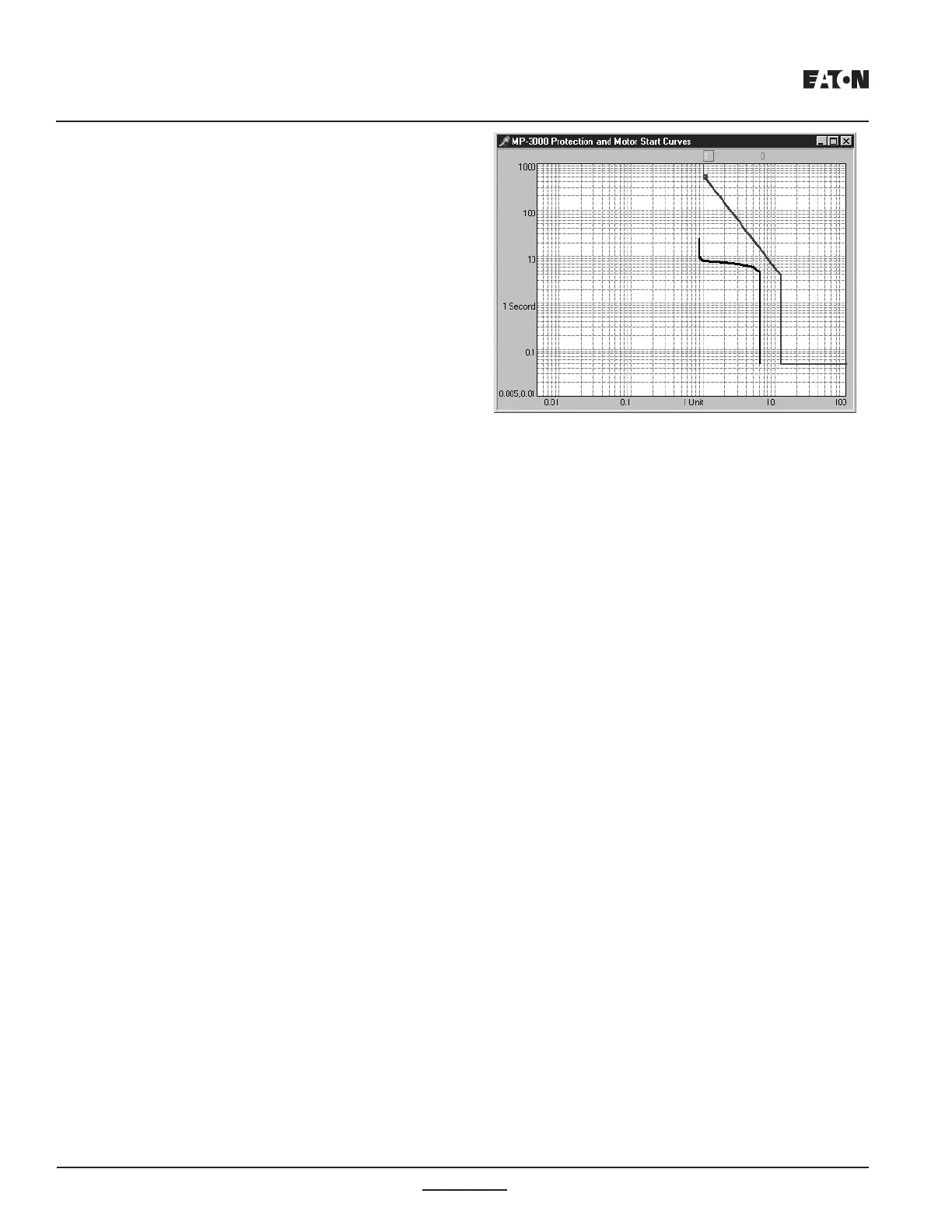

The MP-3000 records the average current and voltage versus time for

the last four starting cycles. This information is available via the com-

munications port. The PowerNet host plots the motor current versus

the motor cold-start protection curve, as shown in Figure 2.1.

The MP-3000 Motor Protection Relay has a User-friendly interface

that makes it easy to retrieve important information or to make set-

ting changes. LEDs provide visual indication of display mode. The

pushbutton access scheme is easy to learn, and quickly accesses the

large volumes of setting, monitoring, logging, and historical

information.

The User may also access settings via the front panel RS-232 port.

The JTAG port is for factory use only.

Loading...

Loading...