Tap-To-Target

Tap To Target is similar to Tap To Neutral except that with

Tap To Target a regulator can be tapped to and held at any

tap position until the feature is deactivated. As with Tap

To Neutral, the feature must first be enabled and then

activated. A third element is also require for Tap To Target

and that is the target tap position.

Enabling Tap To Target can be done by setting FC 171 on the

control to On or by checking a Tap To Target box in ProView

NXG. Tap To Target can be activated using either an analog

input or digital SCADA data point, or using configurable

logic. The third element, target tap position, can be

programmed using FC 172 or entered in the Tap To Neutral

dialog box in ProView NXG.

As a default, there are no analog inputs assigned to activate

the Tap To Target. An analog input can be assigned using

configurable logic in ProView NXG. Assigning one of the

General Purpose Inputs, GPI 1, GPI 2, or GPI 3 would

provide a means to activate the feature by applying either

120 Vac or grounding the terminal board points on the back

panel. The terminal board points are assigned as follows:

GPI 1 is assigned to terminal 5

GPI 2 is assigned to terminal J

GPI 3 is assigned to terminal BR

Making an alternate assignment to a GPI terminal will

deactivate its default fixed functionality.

To activate the feature using digital SCADA, use the data

point Configurable Logic Output From SCADA Tap to

Target Activate.

Remote motor control and auto-tap blocking

Standard, fixed configuration logic programmed into the

control assigns General Purpose Input 3 (GPI 3) to be

the input point for the External Auto Block Active output.

Supplying 120 Vac to the point will inhibit auto-operation

tapping until it is removed. When the motor is controlled

remotely, it is necessary to inhibit automatic operation.

As with the analog input points for voltage reduction, a

whetting voltage from contact point V9 or a 120 Vac whet

contact can be used to activate the auto-tap blocking

feature.

ote:N GPI 3 is assigned to contact point BR as a default.

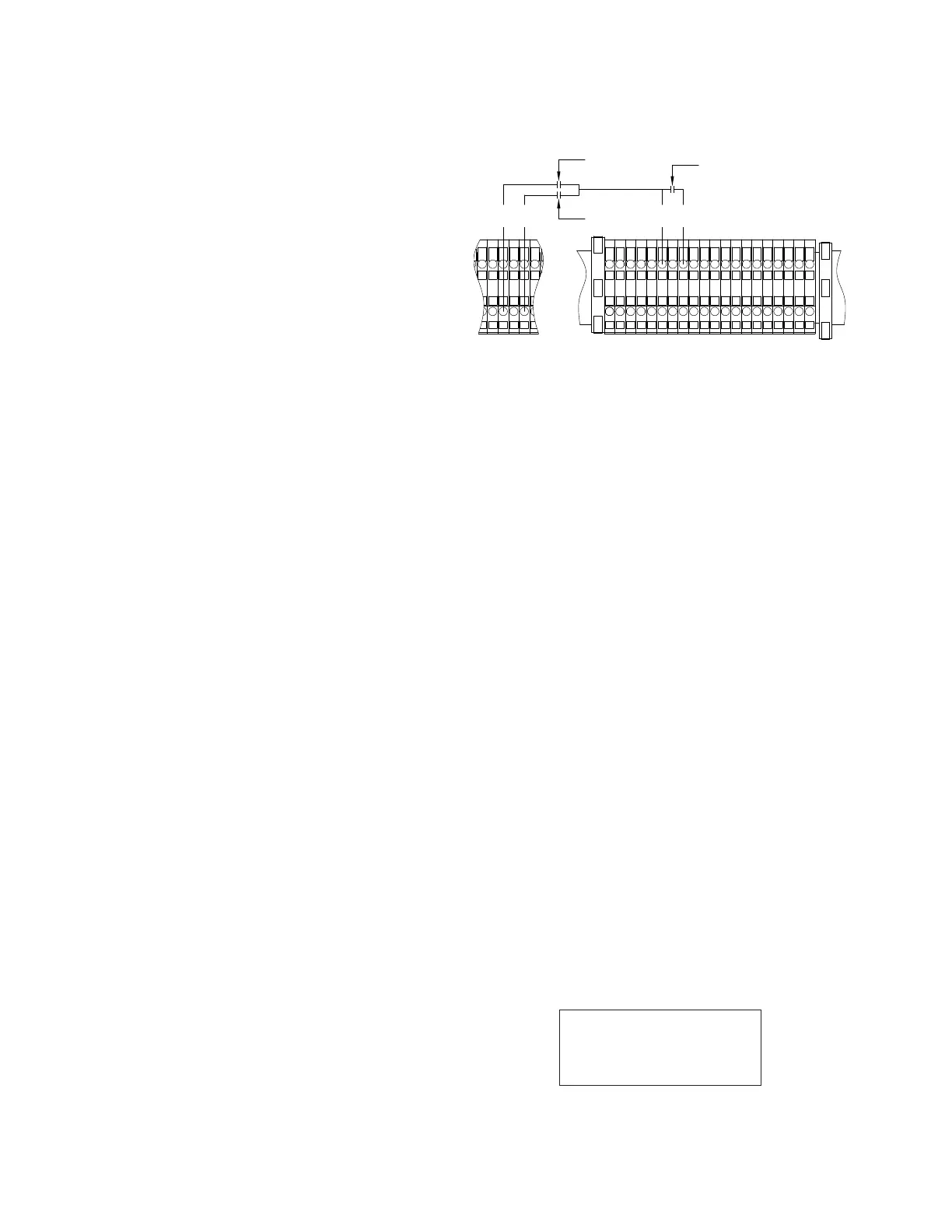

To remotely raise or lower the tap-changer, the appropriate

set of contacts are momentarily closed. Interposing

relays can be used, such that raise and lower contact

closure cannot occur simultaneously. See Figure41 for

recommended connections on a standard back panel with

the TB3 terminal board at the bottom of the control cabinet.

V

9

B

R

L

1

R

1

Control Panel Connection

Raise

Lower

Blocking

Relay

Figure47. Auto-tap blocking and remote motor control

connections shown on the standard back panel with a

TB3 terminal board

Alternate configuration

The CL-7 control panel typically operates with one

set of configuration settings that are programmed or

changed through the keypad or one of the available

communications channels using ProView NXG software.

Alternate Configuration modes allow the CL-7 control to

be programmed with three additional sets of configuration

settings that can then be activated at FC 450. Which

Alternate Configuration is active can be selected at FC 452.

The Alternate Configuration state can be monitored at FC

451 and will display Alt Config 1 Active, Alt Config 2 Active,

Alt Config 3 Active, ARLC Active or ALRH Active.

When an Alternate Configuration mode is activated using

FC 450, a set of alternate configuration settings will become

active and will be used as the basis for the operation of

the control. The control parameters included in the set of

Alternate Configuration settings can be seen in Table9 in

the control menu Features > Alternate Config.

Alternate Configuration settings can be entered using two

methods: 1) Set the individual Alternate Configuration

settings using the control HMI (see Table10 for a list of

applicable function codes). 2) Using ProView NXG software,

enter the Alternate Configuration settings in the Alternate

Configuration Setting dialog box and load the settings using

one of the communications channels.

When the control is in the Alternate Configuration mode,

the display for each of the affected control parameters

will display the statement "(ALT CONFIG X)" at the bottom

where X is the number of the active Alternate Configuration

set. This will indicate that the alternate configuration setting

is active and in use for control operation (see the example

below).

001 Forward

Set Voltage

120.0 Volts

(ALT CONFIG 1)

142

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS MN225003EN April 2018

CL-7 Voltage Regulator Control

Loading...

Loading...