48

ENGINE

CS-370ES

CS-420ES

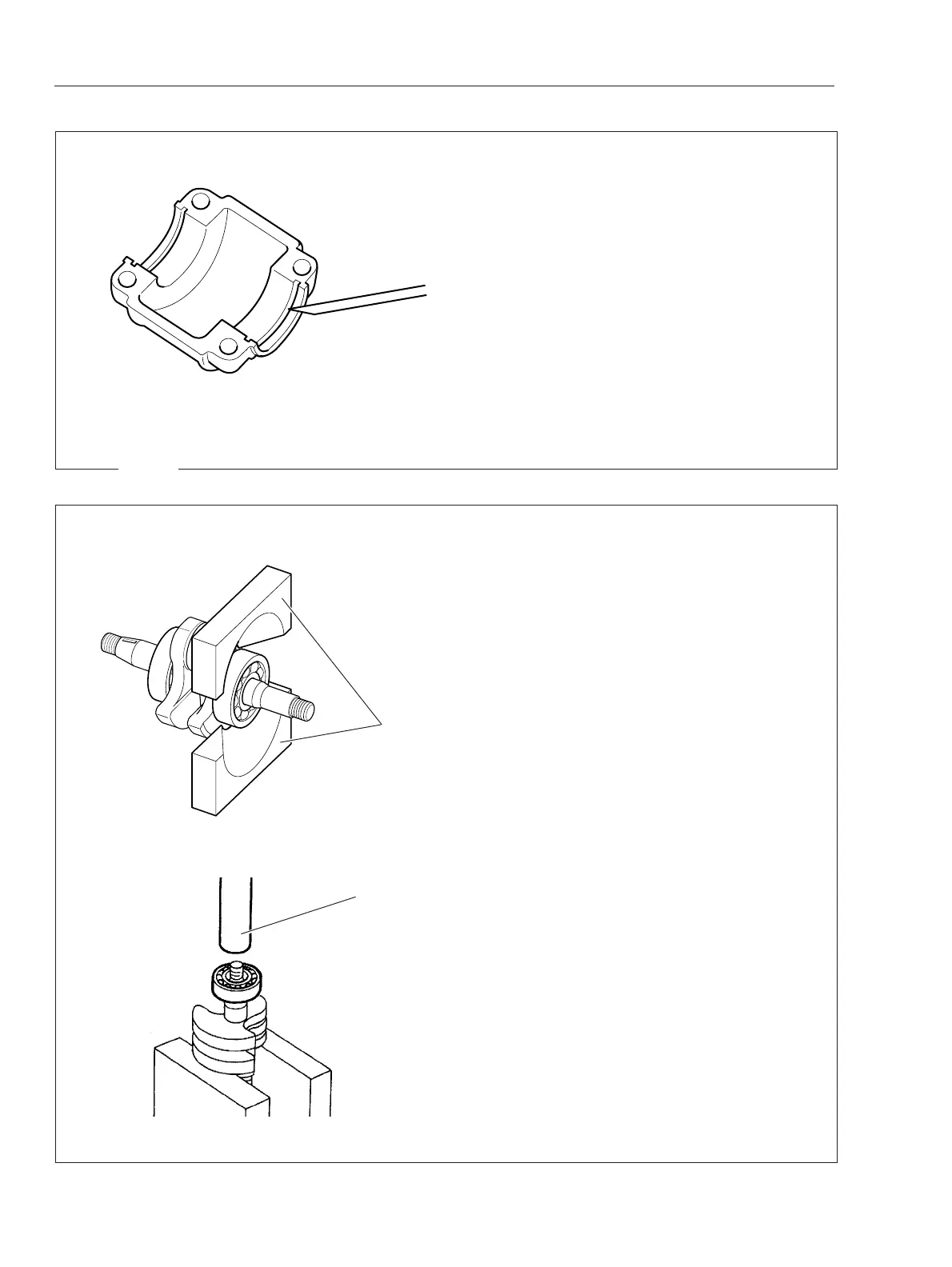

7-9 Replacing oil seal and ball bearing

1. Check oil seal(s) and replace if defective.

2. Check ball bearing(s) for smooth rotation. If not,

remove ball bearing(s) using bearing wedge (A)

897701-02830.

NOTE: When removing the oil seal or ball bearing

at clutch side, worm gear should be removed in

advance (Refer to “6-8 Removing worm gear”).

3. Install new ball bearing(s) onto crankshaft using

bearing/seal tool 897726-09130 (B). Bearing should

be completely seated against crankshaft

counterweights.

NOTE: Preheat ball bearing using heating gun, heat

lamp, or suitable heater for easier installation.

4. Install oil seals onto both ends of crankshaft

insuring proper direction of oil seal.

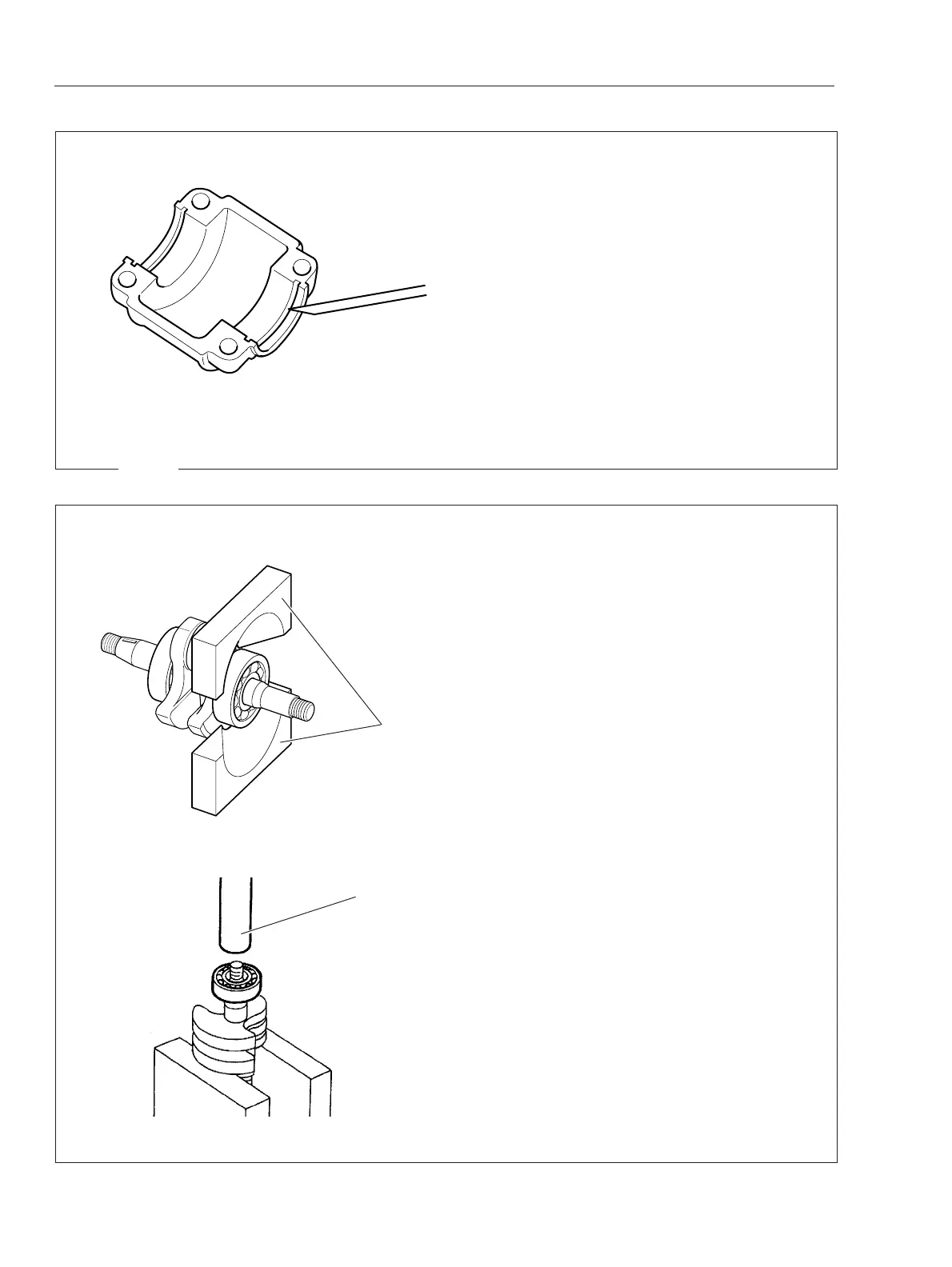

7-8 Inspecting crankcase and crankshaft

1. Clean crankcase. Replace as a set of cylinder

and crankcase if damaged.

2. Completely remove sealant residue on mating

surfaces and bearing bore of crankcase using

wooden or plastic scraper, or chemical gasket

remover.

3. Measure crankshaft runout and replace if it

exceeds service limits (Refer to “1-5”). Replace

crankshaft if the connecting rod bearing is rough,

damaged, or discolored.

A

B

1K264

Loading...

Loading...