Assembly

AssemblyPreparations

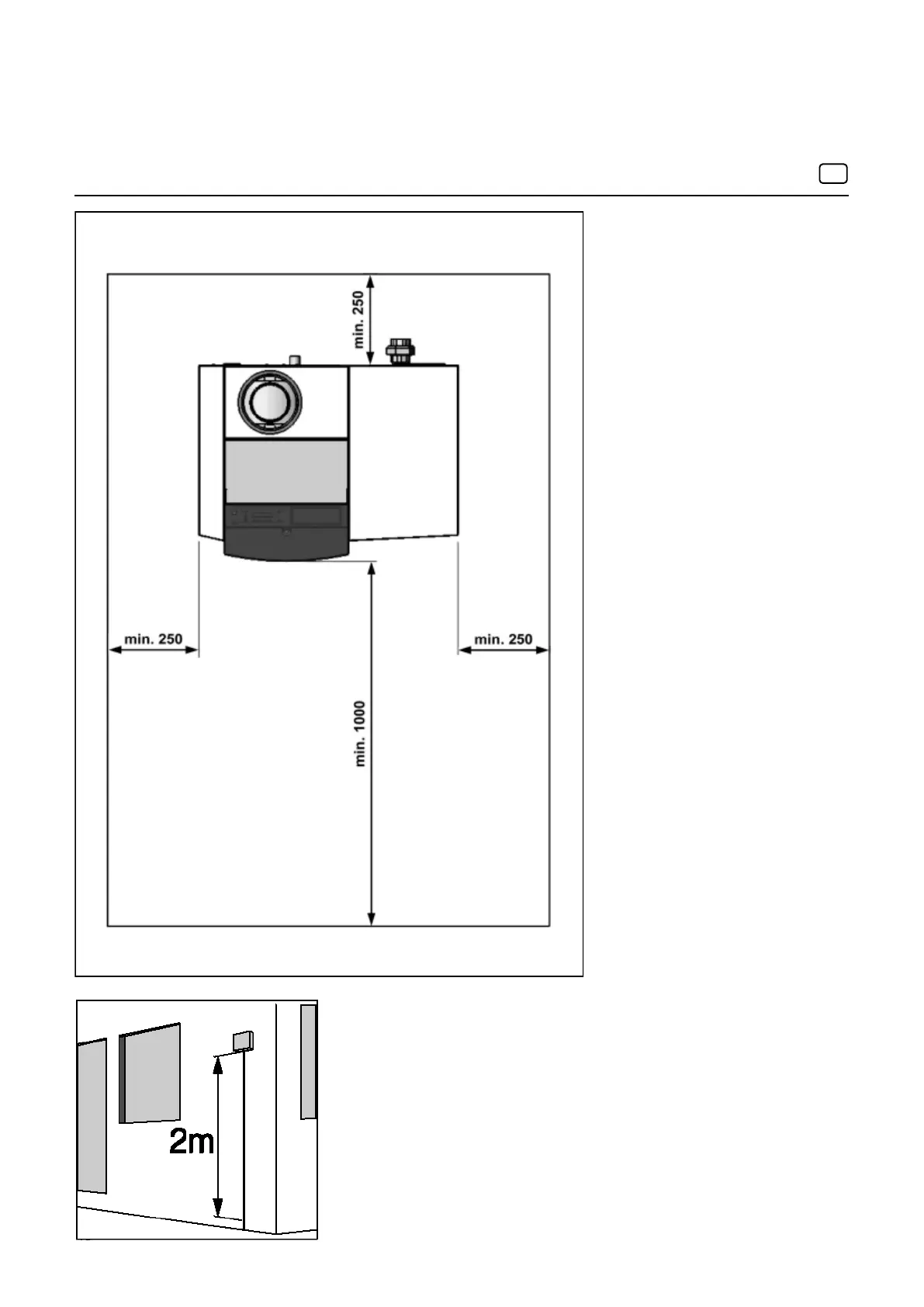

Pla

cementandDistances

Minimumdistancesmustbemaintained

inordertoenablefreeaccessfor

operationandmaintenance.

Placeofinstallation

Thesystemshallnotbeplacedinside

anyroomswithaggressivevapors

(suchashairspray,perchloroethylene,

tetracarbonchlorine),orhighaccumula-

tionofdustorhumidity(suchasa

laundryroom).Theplaceofinstallation

mustbeprotectedagainstfreezing.

Anywarrantyshallbevoidedfor

damagesresultingfromnoncompliance

withtheserequirements.

Whenassemblingtheequipment,care

mustbetakentopreventanyforeign

particles(suchasdrillingdust)from

enteringthegascondensingboiler.

Providecover-ups.Sincevarious

stateshavedifferentregulations,a

follow-upwiththerespectivegovern-

mentagenciesandthedistrictchimney

sweeperinchargeisrecommended.

Gasconnection

Thelayoutofgaspipesandconnection

tothegaslinemustbeperformedby

authorizedgasinstallersonly.Heating

andgaslinesmustbecleanedfrom

anyresidue,particularlyforolder

systems,priortotheconnectionofthe

gascondensingboiler.Caremustbe

takentoensureanon-stressedlayout

ofallgaslines.

Priortocommissioning,allpipecondu-

itsandconnectionsmustbechecked

fortightnessandleaks.Gasfittingsat

theburnermaybepressurechecked

upto150mbar.

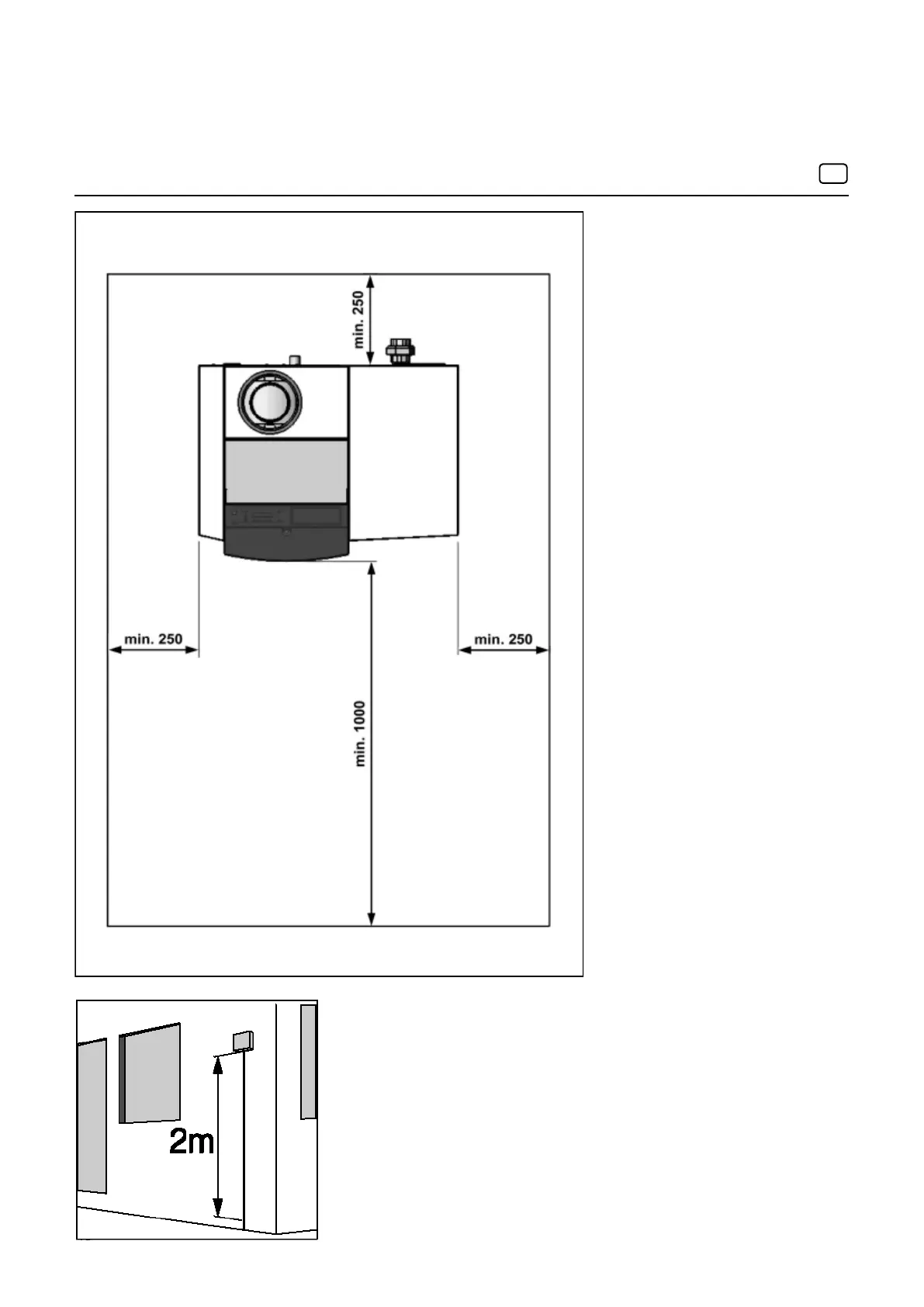

Mo

untexteriortemperaturesensor

Thissensorisnotpre-wired.

Installationsite:

M

inimumof2maboveground,prefe-

rablyonthenorthwallofthebuilding

Makesurethatthesensorisnotaf-

fectedbyfireplaces,windows,etc.

Installationtype:

T

urnthesensorsuchthatthewires

exitthecasingatthebottom.

Conduitlength:

M

aximumof100mwhenusing

NYM3x1mm

2

or

H05

VV-F-3x1mm

2

10

Mi

nimumdistances

e

n

Loading...

Loading...