Loading...

Loading...

Do you have a question about the Emerson FB2200 and is the answer not in the manual?

Understand safety implications before operating the device; keep manual handy.

Consider backup equipment to protect processes from device failure.

Ensure equipment is cleaned to safe levels before returning it.

Ground metal enclosures and exposed metal parts per OSHA and NEC.

Handle ESD-sensitive components carefully to prevent damage.

Identifies potential hazards using specific labels; consult documentation for details.

Lists key features of the FB2200 flow computer.

Describes the two basic models and enclosure options.

Details the CPU type and processor.

Describes the static and flash memory types and capacities.

Lists base I/O and optional expansion modules.

Details options for powering the device.

Describes available communication ports and protocols.

Explains the HMI module's display and LEDs.

Details wireless communication capabilities.

Introduces the FBxConnect configuration software.

States compliance with RoHS2 EU Directive.

Discusses methods for securing the enclosure.

Certifications for Class I Division 2 and ATEX Zone 2.

Summarizes environmental parameters for the device.

Lists tools needed for installation and servicing.

Factors to consider for installation location.

Best practices for wiring connections.

Instructions for properly grounding the unit.

Procedures for opening and closing the enclosure.

Methods for mounting the flow computer.

Guidelines for bolting flange assemblies.

Proper use and inspection of O-rings.

Instructions for pole mounting aluminum enclosures.

Instructions for pole mounting fiberglass enclosures.

Dimensions for mounting aluminum enclosures on panels/walls.

Dimensions for mounting fiberglass enclosures on panels/walls.

How to rotate the housing for accessibility.

Explains Low Power and Standard Power modes.

Instructions for connecting DC and battery/solar power.

Steps for installing the solar panel kit.

How to set the solar panel tilt angle.

Guidance for connecting communication cables.

Information on the door contact terminal.

Details the available analog input channels and configurations.

Details the available analog output channels and configurations.

Details the available digital input channels and configurations.

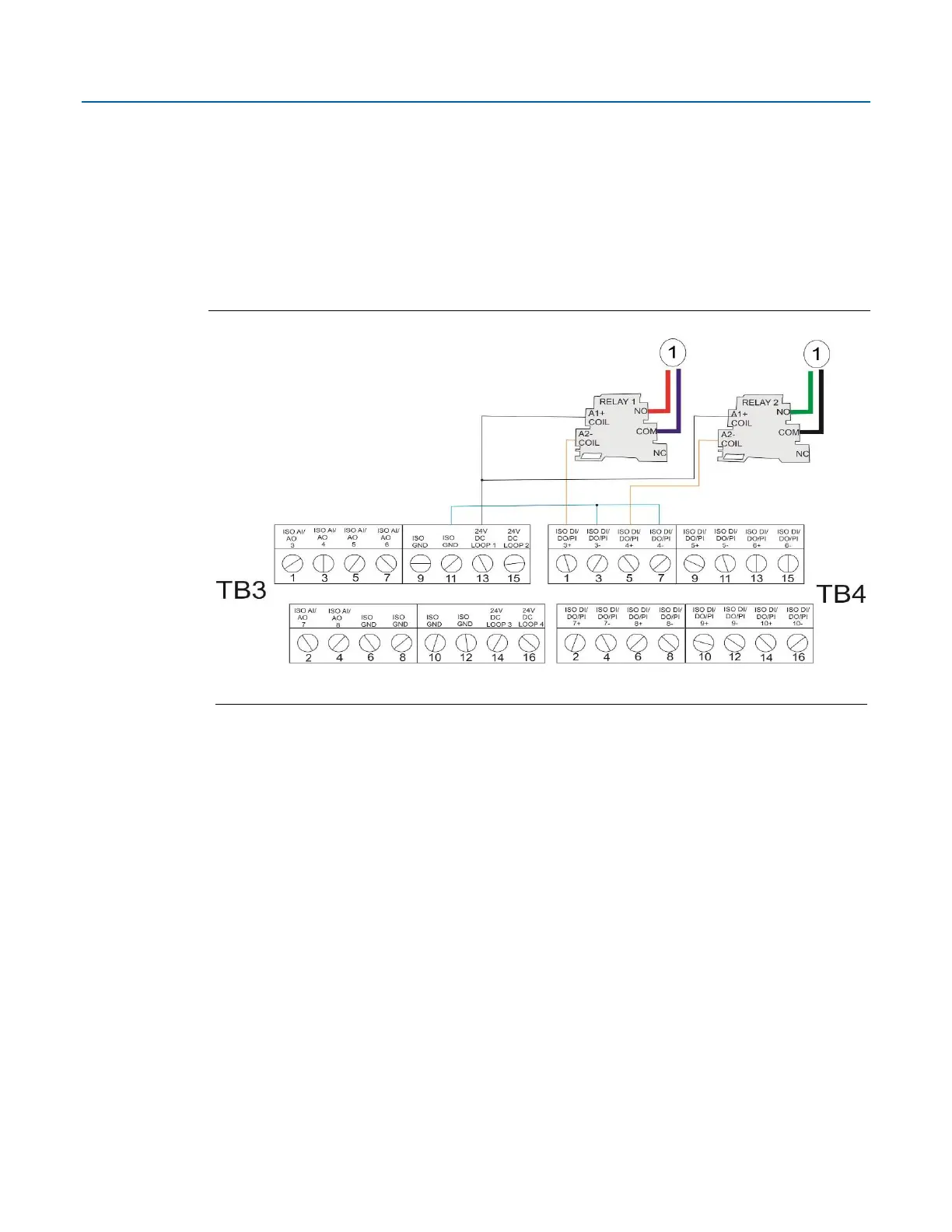

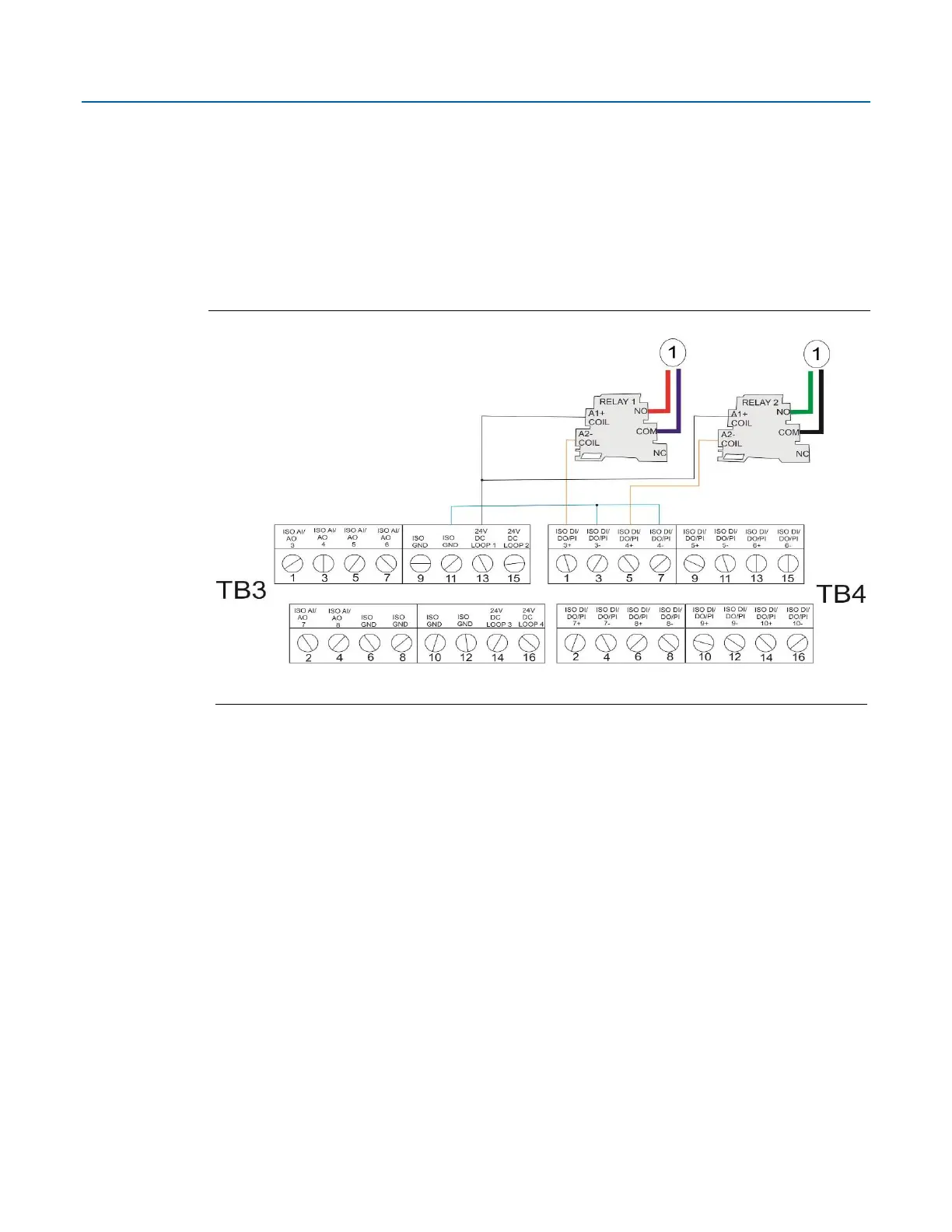

Details the available digital output channels and configurations.

Details the available pulse input channels and configurations.

Instructions for connecting RTD/PRT sensors.

How to connect the 4088B transmitter.

Wiring digital outputs to relays.

Instructions for wiring radio components.

Procedures for turning the device on and off.

Methods for establishing communication with the device.

How to communicate using the HMI module.

Procedure for returning the unit for service.

Explains the meaning of the status LEDs.

Describes the function of switches and buttons for troubleshooting.

Steps for removing and replacing the HMI module.

Procedure for replacing the main battery.

Steps for replacing the SRAM backup battery.

How to update the system firmware.

Requirements for Class I Division 2 hazardous locations.

Notes on ATEX certifications for Zone 2.