Instruction Manual

D102748X012

DLC3010 Digital Level Controller

Introduction and Specifications

May 2018

11

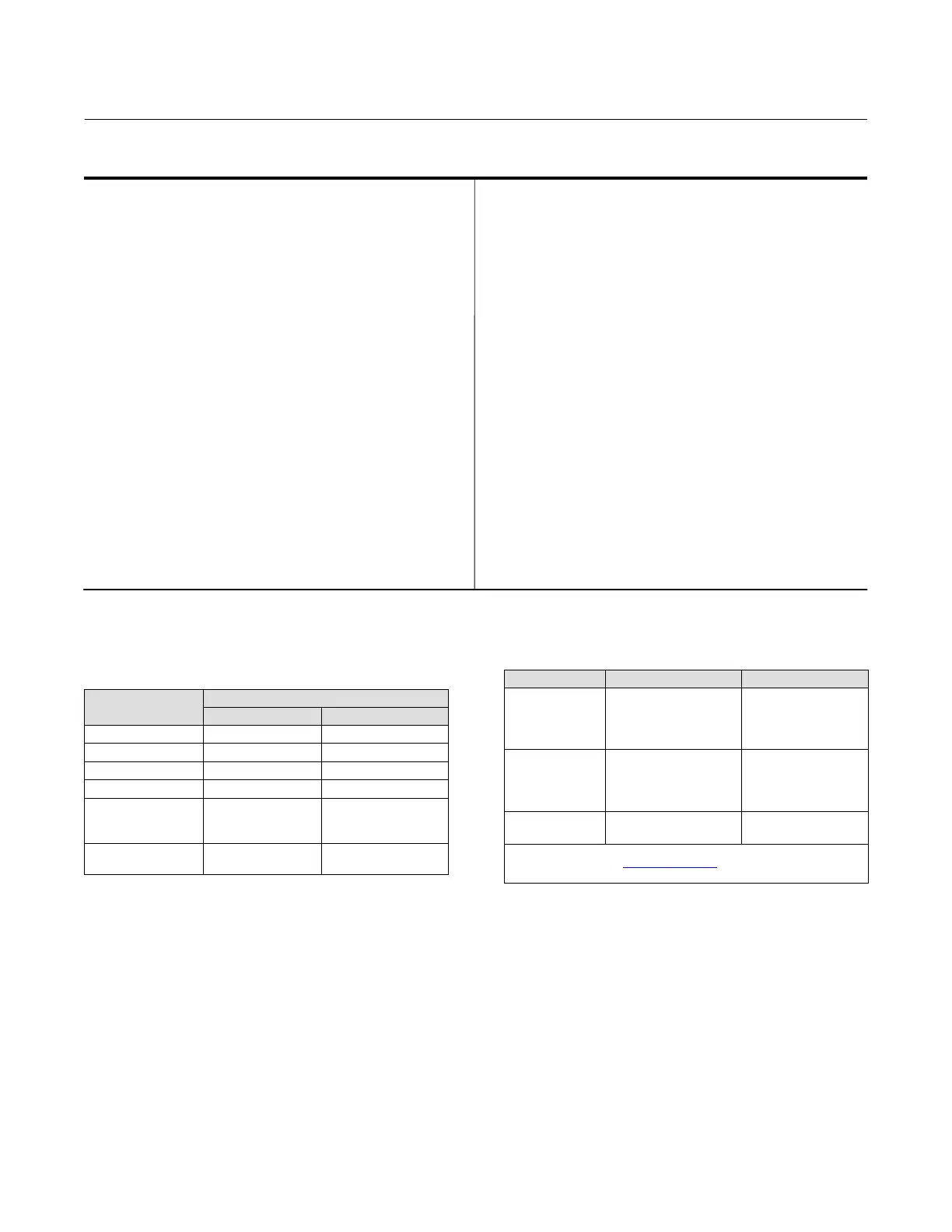

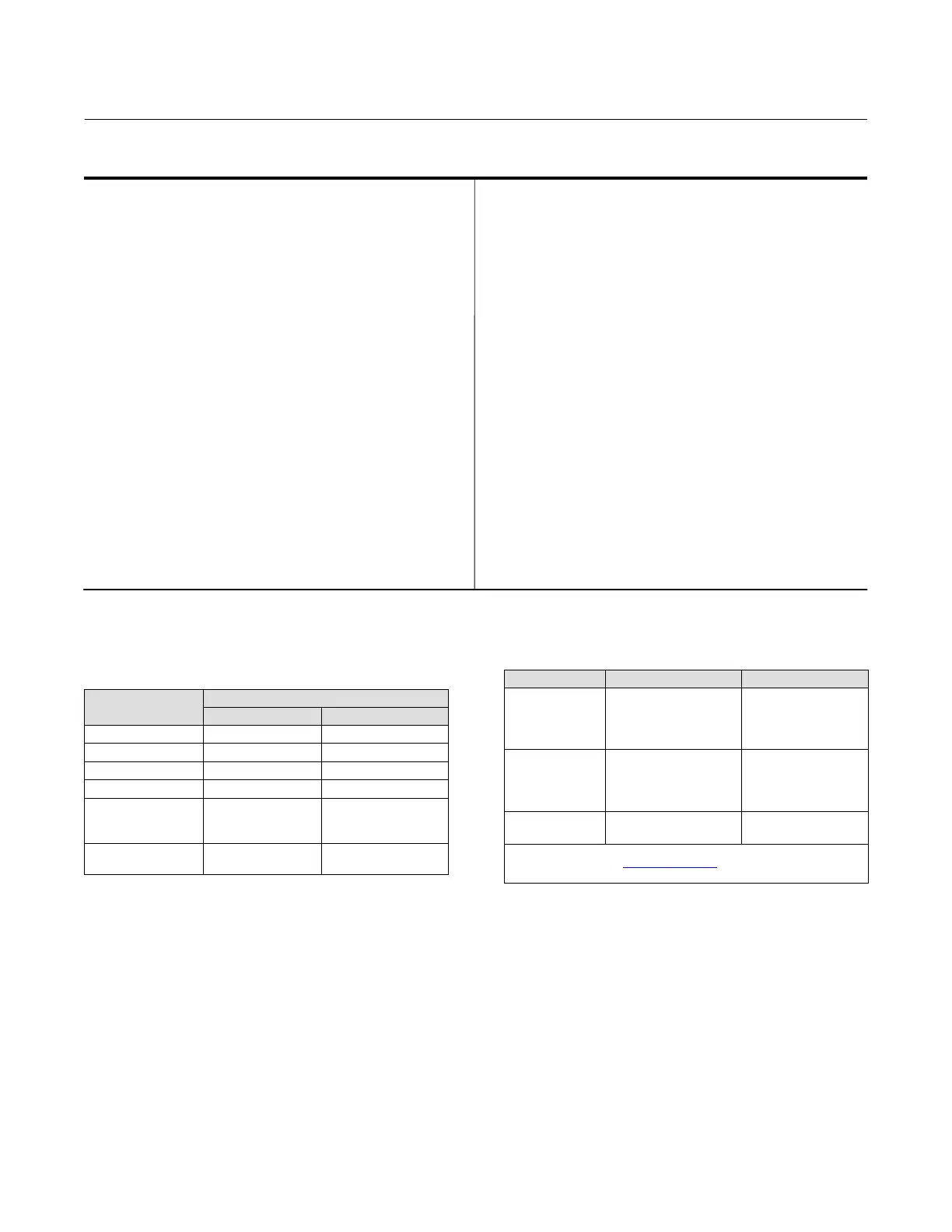

Table 1‐3. 249 Sensor Specifications

Input Signal

Liquid Level or Liquid‐to‐Liquid Interface Level:

From 0 to 100 percent of displacer length

Liquid Density: From 0 to 100 percent of

displacement force change obtained with given

displacer volume—standard volumes are

J980 cm

3

(60 inches

3

) for 249C and 249CP sensors or J1640

cm

3

(100 inches

3

) for most other sensors; other

volumes available depending upon sensor

construction

Sensor Displacer Lengths

See tables 1‐6 and 1‐7 footnotes

Sensor Working Pressures

Consistent with applicable ANSI

pressure/temperature ratings for the specific sensor

constructions shown in tables 1‐6 and 1‐7

Caged Sensor Connection Styles

Cages can be furnished in a variety of end connection

styles to facilitate mounting on vessels; the

equalizing connection styles are numbered and are

shown in figure 1‐4.

Mounting Positions

Most level sensors with cage displacers have a

rotatable head. The head may be rotated through

360 degrees to any of eight different positions, as

shown in figure 2‐5.

Construction Materials

See tables 1‐5, 1‐6, and 1‐7

Operative Ambient Temperature

See table 1‐4

For ambient temperature ranges, guidelines, and use

of optional heat insulator, see figure 2‐7.

Options

J Heat insulator J Gauge glass for pressures to 29

bar at 232_C (420 psig at 450_F), and

J Reflex

gauges for high temperature and pressure

applications

Table 1‐4. Allowable Process Temperatures for

Common 249 Sensor Pressure Boundary Materials

MATERIAL

PROCESS TEMPERATURE

Min. Max.

Cast Iron -29_C (-20_F) 232_C (450_F)

Steel -29_C (-20_F) 427_C (800_F)

Stainless Steel -198_C (-325_F) 427_C (800_F)

N04400 -198_C (-325_F) 427_C (800_F)

Graphite

Laminate/SST

Gaskets

-198_C (-325_F) 427_C (800_F)

N04400/PTFE

Gaskets

-73_C (-100_F) 204_C (400_F)

Table 1‐5. Displacer and Torque Tube Materials

Part Standard Material Other Materials

Displacer 304 Stainless Steel

316 Stainless Steel,

N10276, N04400,

Plastic, and Special

Alloys

Displacer Stem

Driver Bearing,

Displacer Rod

and Driver

316 Stainless Steel

N10276, N04400,

other Austenitic

Stainless Steels, and

Special Alloys

Torque Tube N05500

(1)

316 Stainless Steel,

N06600, N10276

1. N05500 is not recommended for spring applications above 232_C

(450_F). Contact your Emerson sales office

or application engineer if

temperatures exceeding this limit are required.

Loading...

Loading...