106 Micro Motion

®

Model 1500 Transmitters with the Filling and Dosing Application

Troubleshooting

11.23.3 Excessive drive gain

Excessive drive gain can be caused by several problems. See Table 11-8.

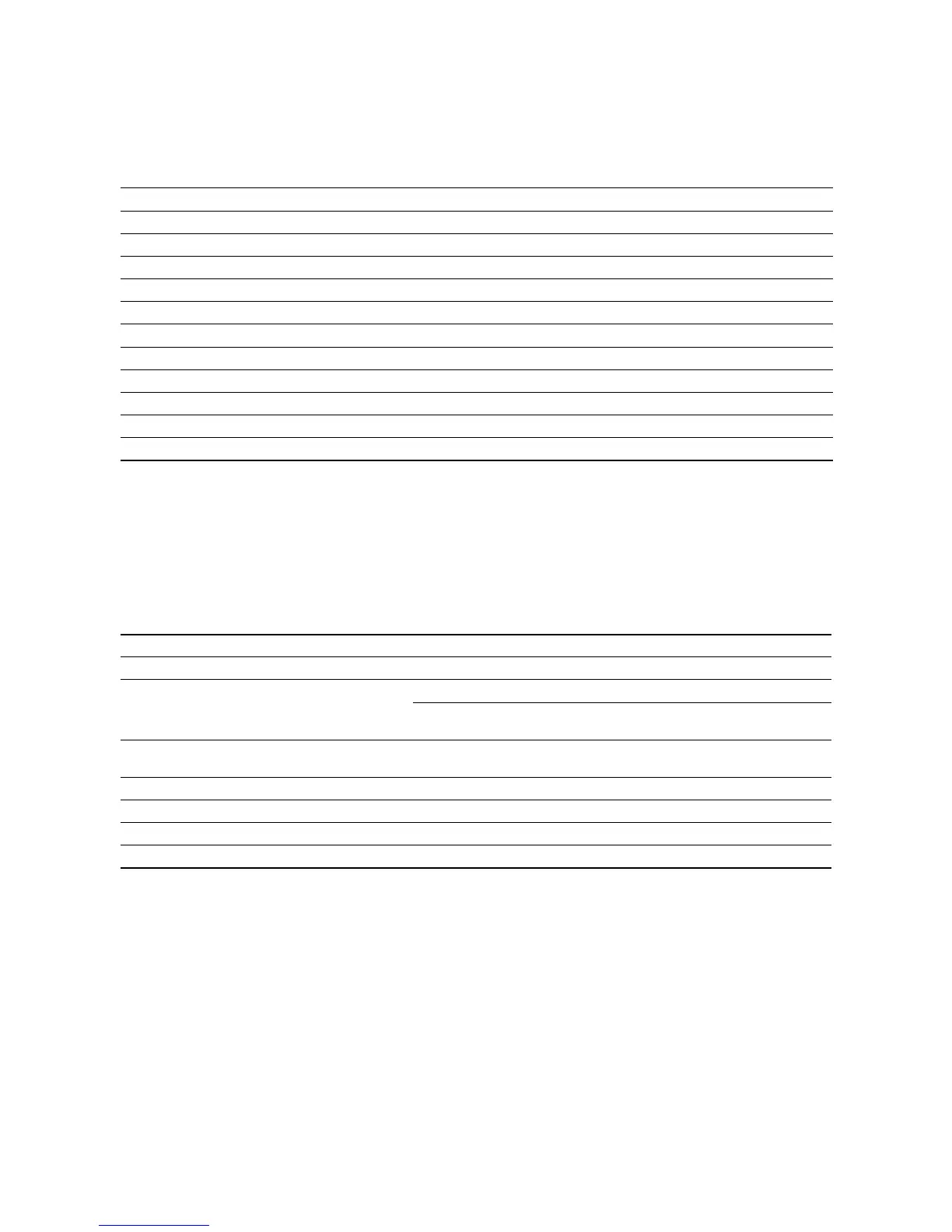

Table 11-7 Sensor pickoff values

Sensor

(1)

(1) If your sensor is not listed, contact Micro Motion. See Section 1.8

Pickoff value

ELITE Model CMF sensors 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model D, DL, and DT sensors 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model F025, F050, F100 sensors 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model F200 sensors (compact case) 2.0 mV peak-to-peak per Hz based on sensor flow tube frequency

Model F200 sensors (standard case) 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model H025, H050, H100 sensors 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model H200 sensors 2.0 mV peak-to-peak per Hz based on sensor flow tube frequency

Model R025, R050, or R100 sensors 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

Model R200 sensors 2.0 mV peak-to-peak per Hz based on sensor flow tube frequency

Micro Motion T-Series sensors 0.5 mV peak-to-peak per Hz based on sensor flow tube frequency

CMF400 I.S. sensors 2.7 mV peak-to-peak per Hz based on sensor flow tube frequency

CMF400 sensors with booster amplifiers 3.4 mV peak-to-peak per Hz based on sensor flow tube frequency

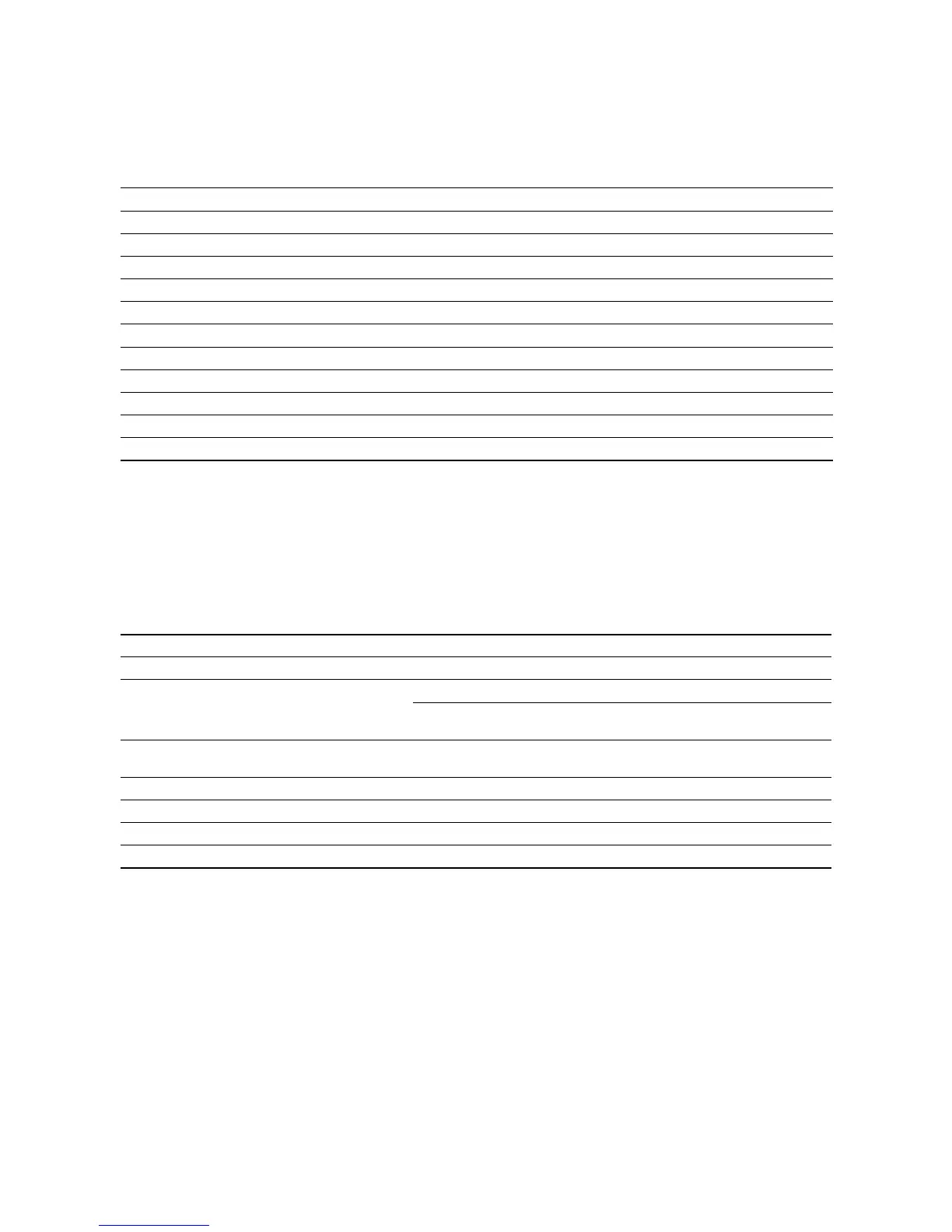

Table 11-8 Excessive drive gain causes and remedies

Cause Possible remedy

Excessive slug flow See Section 11.17.

Plugged flow tube Purge the flow tubes.

Cavitation or flashing Increase inlet or back pressure at the sensor.

If a pump is located upstream from the sensor, increase the distance

between the pump and sensor.

Drive board or module failure, cracked flow tube,

or sensor imbalance

Contact Micro Motion. See Section 1.8.

Mechanical binding at sensor Ensure sensor is free to vibrate.

Open drive or left pickoff sensor coil Contact Micro Motion. See Section 1.8.

Flow rate out of range Ensure that flow rate is within sensor limits.

Incorrect sensor characterization Verify characterization. See Section 4.2.

Loading...

Loading...