Frontier Oil Heat – PN 10-2021 – October 2021 - 20 -

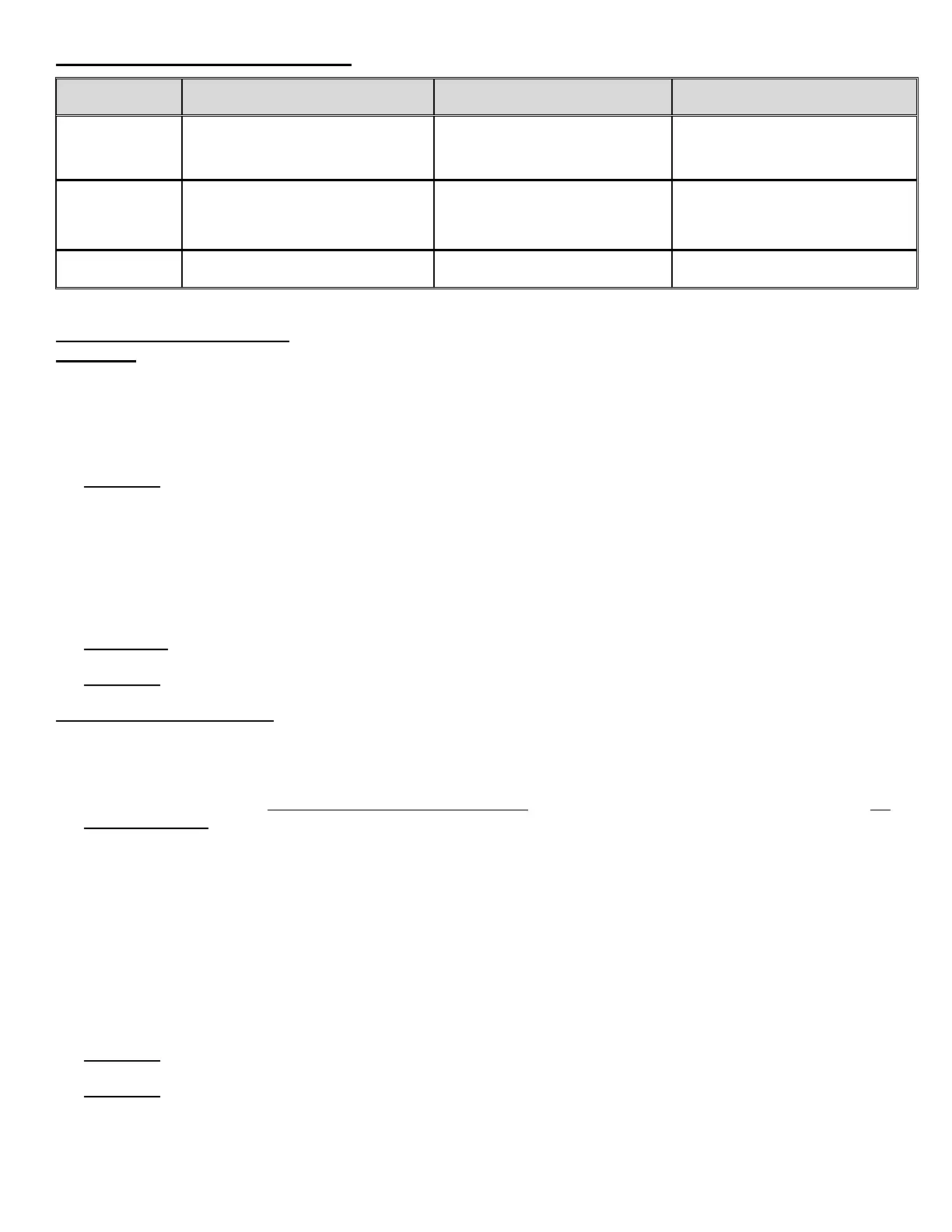

HYDRONIC CONTROL SETTINGS

Auto Reset High Limit

Auto Reset LWCO

Manual Reset Lock Out Temp

DualGard Model: 2450-1

Energy Kinetics PN: 10-0596

215

o

F Auto Reset High Limit

10

o

F Differential (215

o

/205

o

F)*

250

o

F Manual Reset Fixed Max

Frontier Boiler

w/Commercial

Kit

Auto Reset High Limit Aquastat

Manual Reset LWCO

Manual Reset Lock Out Temp

DualGard Model: 2450-2

Energy Kinetics PN: 10-0596-M

215

o

F Auto Reset High Limit

10

o

F Differential (215

o

/205

o

F)*

250

o

F Manual Reset Fixed Max

Energy Kinetics PN: 10-0414

‘Hot’, pointer points to 6 pm.

(To suit individual installation)

For legacy controls, contact Energy Kinetics

* Factory Setting

PREPARE FOR START UP

DANGER: MAKE CERTAIN THE FOLLOWING REQUIREMENTS HAVE BEEN SATISFIED BEFORE START UP:

1. The boiler and piping are completely filled with water.

2. Re-check wiring to ensure that it is correct and in accordance with appropriate wiring diagrams and codes.

3. Verify that proper nozzle is used and installed correctly.

4. Verify electrode settings.

5. Verify the burner settings for air band position and head position (See "Oil Burner Settings" Table).

6. Oil supply is connected to burner. Oil supply lines and shut-off valves are open.

7. CAUTION: DO NOT USE GASOLINE, CRANKCASE DRAININGS, OR ANY OIL CONTAINING GASOLINE.

8. Fuel pump and fuel lines are purged.

9. Verify operating oil pressure at gauge port.

10. Adjust bypass valve on boiler side to heat exchanger ½ way open (See #4 under “Oil Burner Operation”).

11. Flue pipe properly connected from unit to chimney. All joints are secured and sealed.

12. Combustion air supply is available and sufficient. (See “Combustion Air”)

13. Adjust valve in domestic hot water circuit under circulator approximately ¾ of the way open.

14. Loosen the 1/8” brass plug from the flue box test port next to the puff switch (for flue gas temperature) and loosen 1/8”

brass plug in from the “over fire” test port (to right of burner) for the over fire sampling location.

15. CAUTION: All covers, enclosures, and guards must be maintained in place at all times, except during maintenance

and servicing.

16. CAUTION: Do not start burner unless the front door is closed and the nuts have been properly tightened.

START UP PROCEDURE

1. Turn on system supply switch and burner supply switch. The Energy Manager lights should come on briefly, the

circulator relay should close briefly, and then the Energy Manager should only show one red light next to 'power'.

2. The hot water tank aquastat should call for heat, if not, adjust a thermostat to call for heat. Burner and main circulator

should come on at the same time. If not, check primary control and reset it if necessary.

3. Check for burner light off. On an oil supply system with one pipe, it will be necessary to bleed air from fuel pump. On

a two pipe system, several starts may be required to clear air from fuel pump, or bleed air from pump.

4. On light off, water temperature and chimney temperature will start to rise. A slight odor is common on initial light off

as combustion chamber and converter surfaces warm for the first time.

5. NOTICE: Perform smoke test immediately after light off. Smoke test should show yellow after initial one minute of

operation due to the combustion chamber sizing heating up. If the smoke test shows dark grey or black after one

minute of operation, shut off boiler immediately and repeat "Prepare for Start Up" checklist.

6. As Unit reaches temperature, Energy Manager “Heating” light will signal heat distribution to zone(s) calling for heat.

(On first start up, this will usually be the hot water storage tank zone.) Once boiler water temperature reaches 160

o

–

180

o

F., adjust hot water temperature flowing to storage tank. With hot water flowing fully from a domestic faucet,

adjust valve under domestic circulator pump so water temperature going into tank is approximately 140

o

F. (Hand can

be held on pipe just briefly.) Water must be flowing fully from a household hot water tap to accurately adjust flow and

temperature entering tank.

7. Allow system to run about 15 minutes before testing and recording burner operation. (See "Oil Burner Operation")

8. CAUTION: Do not attempt to start the burner when excess oil has accumulated, when the unit is full of vapor, or

when the combustion chamber is very hot.

9. CAUTION: NEVER BURN GARBAGE OR PAPER IN THE UNIT, AND NEVER LEAVE COMBUSTIBLE MATERIAL

AROUND IT.

Loading...

Loading...