Safety and operating instructions

44 © Construction Tools GmbH | 3390 5201 01 | 2023-05-15

Original Instructions

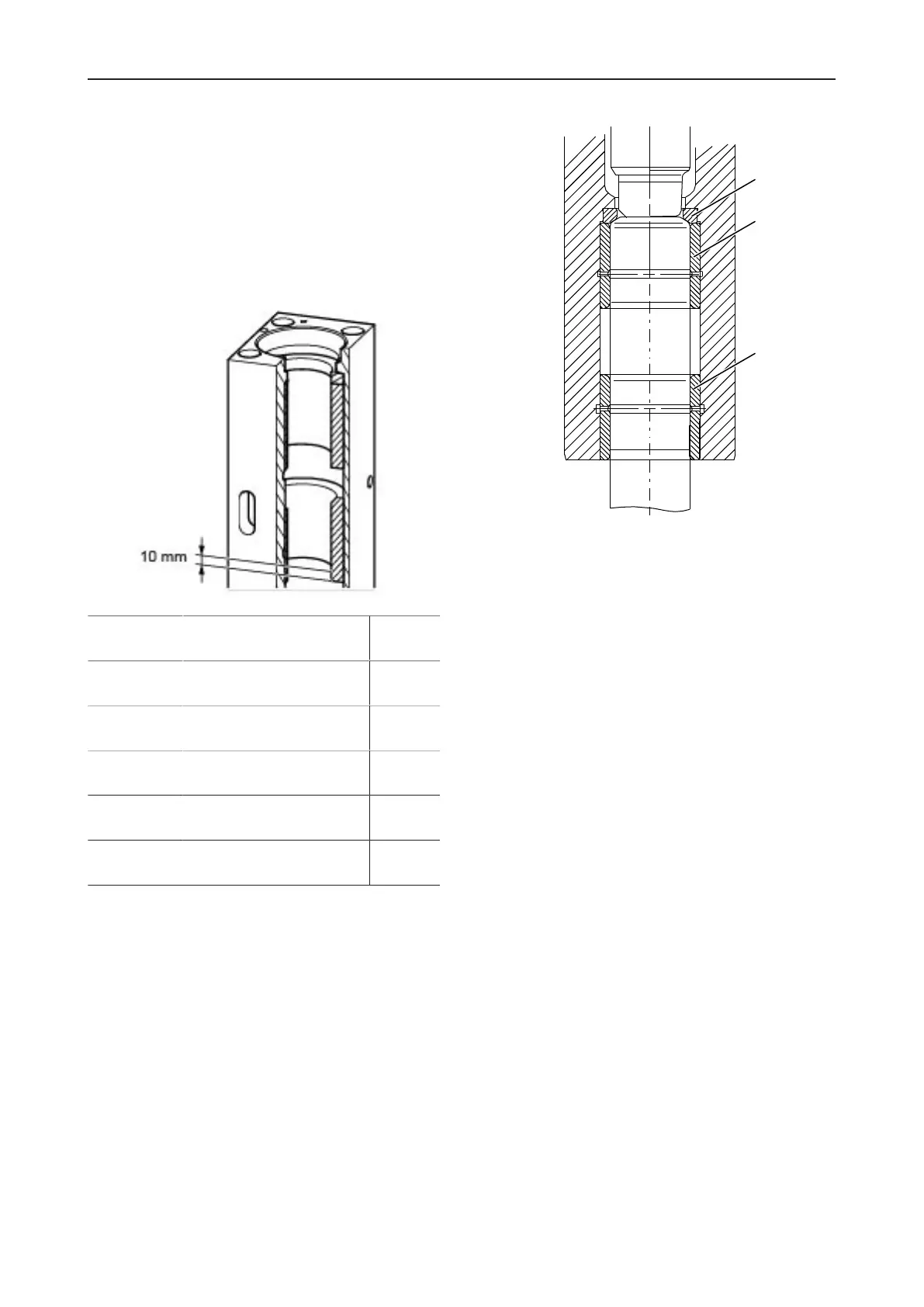

7.9 Checking the wear bushes

and impact ring

The wear bushes can be checked after removing the

working tool. You can check the diameter using the en-

closed test gauge. The diameter measured must not ex-

ceed the maximum permissible diameter D

max

(measur-

ing point see below).

Type Size information on test

gauge

D

max

MB750 E Ø100 103 mm

(4.06in.)

MB1000 E Ø110 115 mm

(4.53in.)

MB1200 E Ø120 125 mm

(4.92in.)

MB1500 E Ø135 140 mm

(5.51in.)

MB1650 E Ø140 145 mm

(5.71in.)

n

Check the inside diameter of the lower and upper

wear bush whenever replacing the working tool, but

at least once every 100operating hours.

n

Clean the area around the impact ring to enable a

visual check.

The lower wear bush can be replaced on site. Consult

the Epiroc Customer Center / Dealer in your area.

n

Remove all remnants of lubricant from the inside of

the lower breaker part before installing new parts.

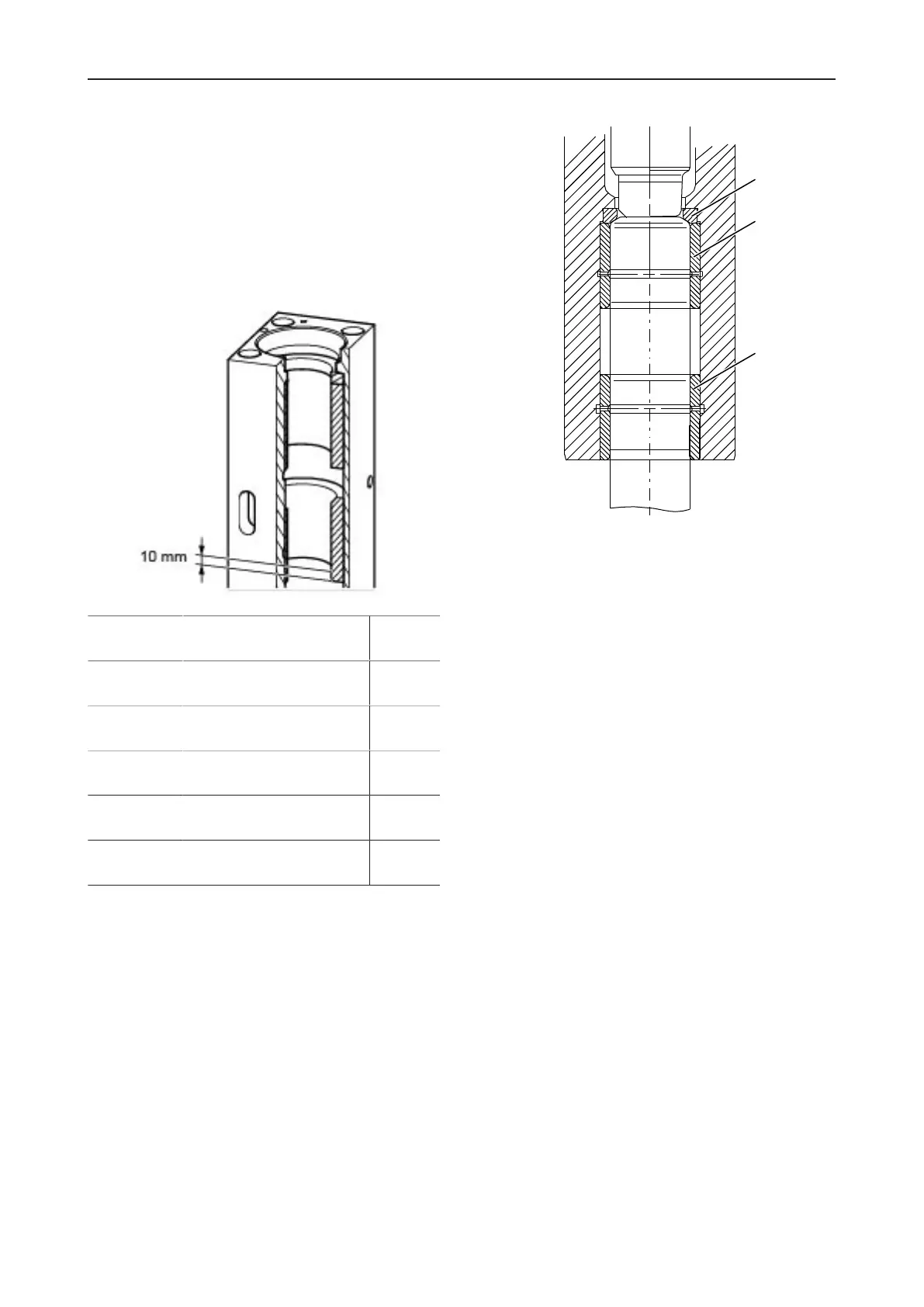

A. impact ring

B. upper wear bush

C. lower wear bush

The upper wear bush and the impact ring must be re-

placed in a workshop fitted out for this purpose.

n

Replace the lower wear bush when its inside diame-

ter is greater than the maximum permissible diame-

ter.

n

When replacing the lower wear bush check the inside

diameter of the upper wear bush using inside cal-

lipers (partnumber3363094952).

n

Replace the upper wear bush and the impact ring

when the inside diameter is greater than the maxi-

mum permissible diameter.

n

Replace the impact ring if you find chips and cracks.

Loading...

Loading...