Safety and operating instructions

48 © Construction Tools GmbH | 3390 5201 01 | 2023-05-15

Original Instructions

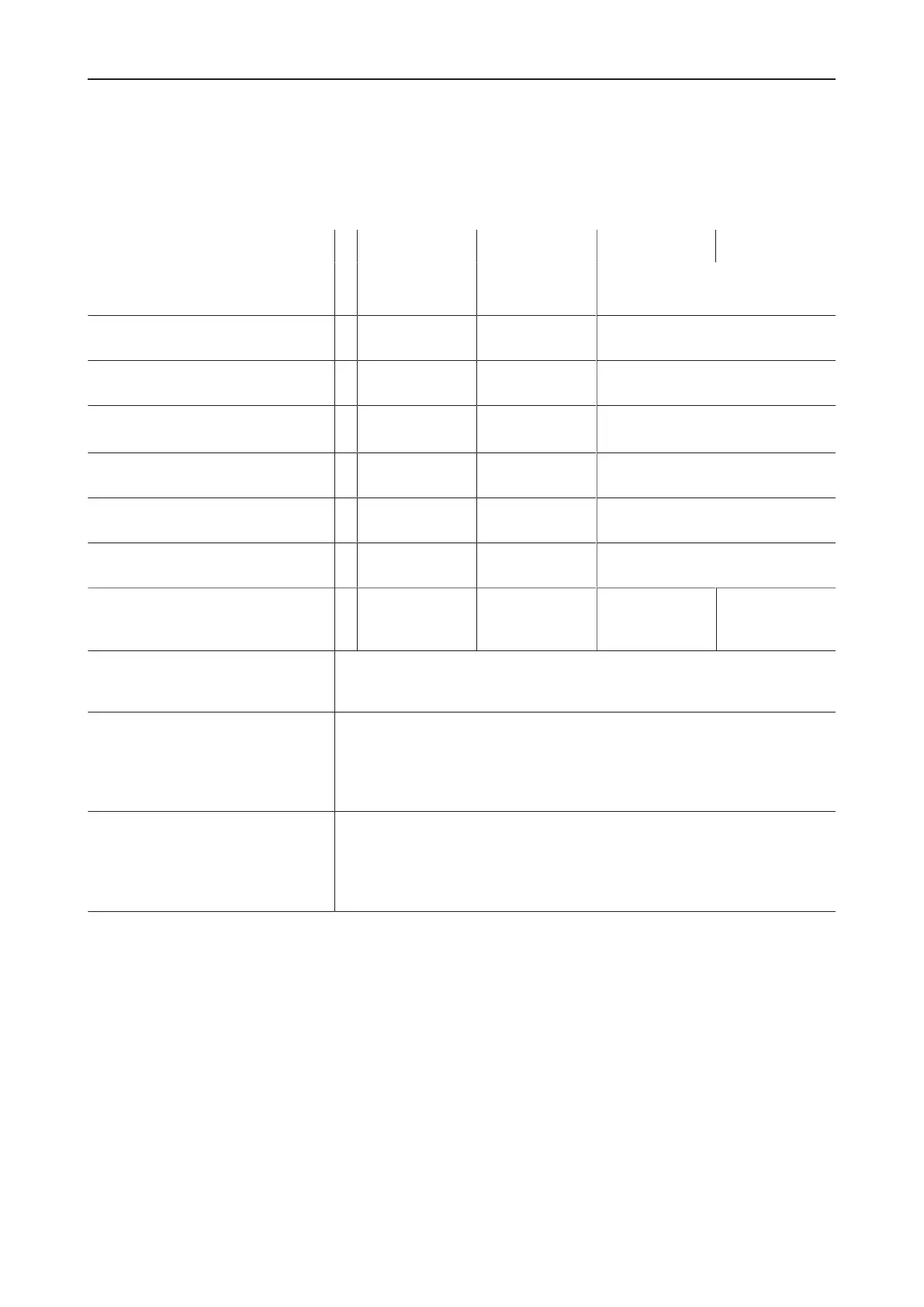

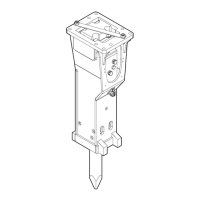

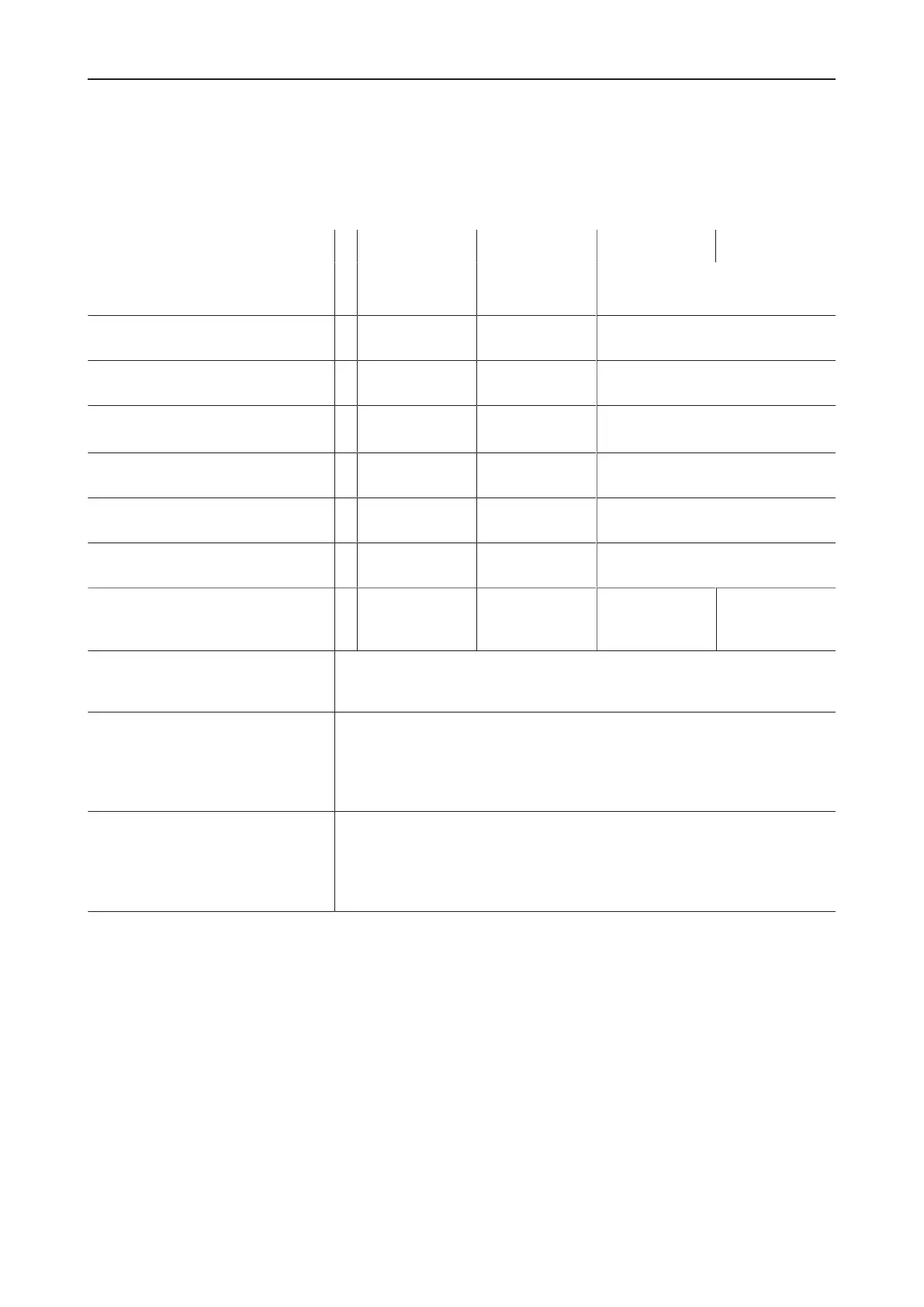

7.15 Bolt connections / Tightening torques MB750 E, MB1000 E

The bolt connections of hydraulic breakers are subjected to very high loads.

n

Tighten any loose connections without exceeding the recommended tightening torques.

MB750 E MB1000 E

Connection point Interval Type of span-

ner

Size / Torque

Adapter plate* (fastening screws) A daily Allen key 17mm (0.67in.) / 390Nm

(288ftlbs)

Tensioning bolts** B weekly visual

check

Torque spanner/

power wrench

50mm (1.97in.)

Filling valve »G« (threaded plug) C in case of a re-

pair

socket spanner

Allen key

22mm (0.87in.) / 130Nm (96ftlbs)

5mm (0.20in.) / 20Nm (15ftlbs)

Ports »P« and »T« D weekly open-ended

wrench

50mm (1.97in.) / 275Nm

(203ftlbs)

Valve (HV) E in case of a re-

pair

Allen key 12mm (0.47in.) / 100Nm (74ftlbs)

Percussion chamber ventilation F in case of a re-

pair

open-ended

wrench

41mm (1.61in.) / 200Nm

(148ftlbs)

AutoControl System G in case of a re-

pair

Allen key - 24mm (0.95in.)

350Nm

(258ftlbs)

* Apply anti-seize compound to the allen screw threads before inserting them.

The contact faces of the screw head and the lock washers must not be lubri-

cated.

**MB750 E The tensioning bolt heads can be seen through the openings in the breaker

box.

1. Pre-tighten the tensioning bolts to 200Nm (148ftlbs) crosswise,

2. retighten 120° (2 hexagons) crosswise,

3. retighten 90° (1.5 hexagons) crosswise

**MB1000 E The tensioning bolt heads can be seen through the openings in the breaker

box.

1. Pre-tighten the tensioning bolts to 200Nm (148ftlbs) crosswise,

2. retighten 120° (2 hexagons) crosswise,

3. retighten 120° (2 hexagons) crosswise

Loading...

Loading...