Safety and operating instructions

© Construction Tools PC AB | 9800 0908 01 | 2023-05-12

Original Instructions

15

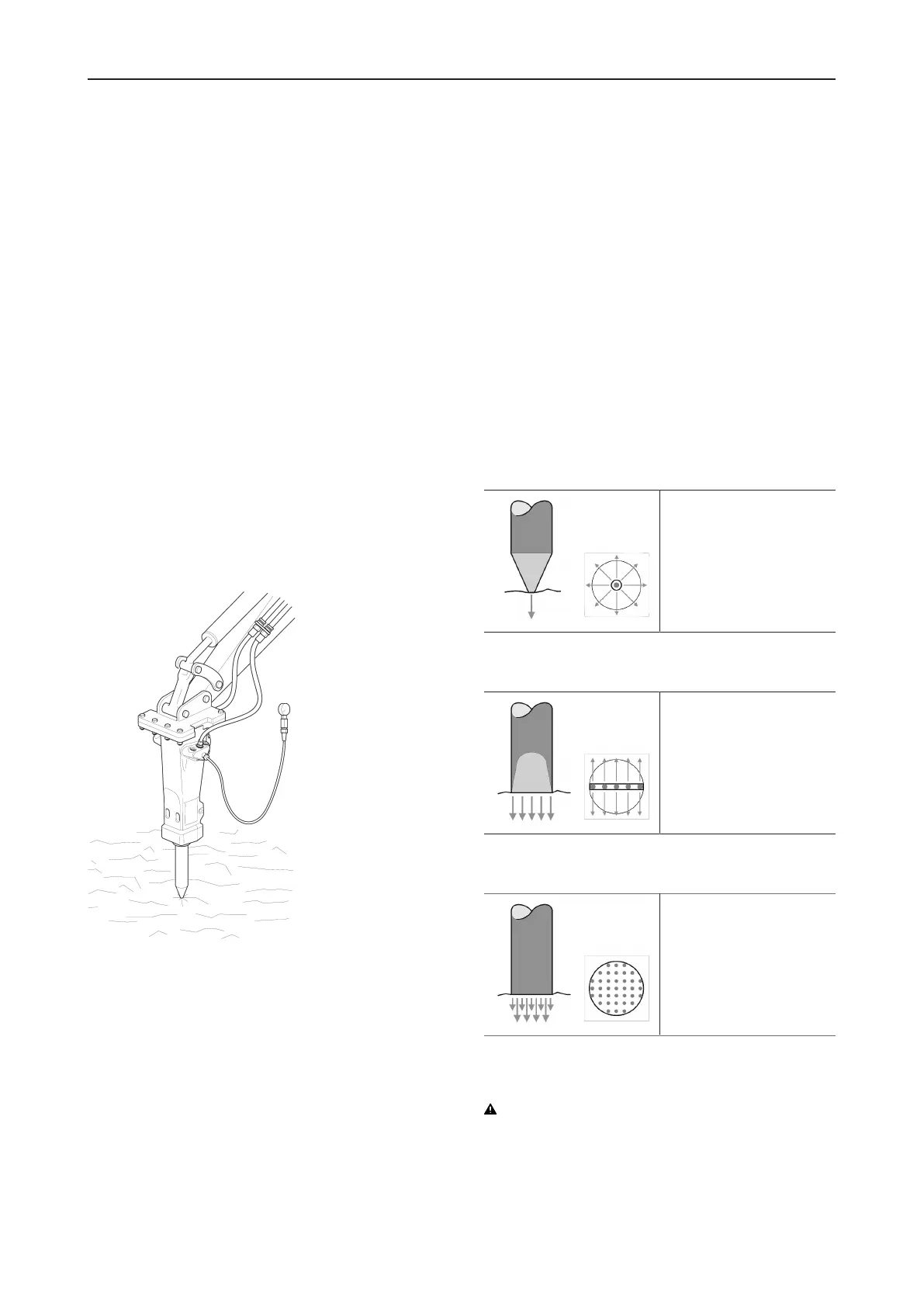

5.4 Pressure adjustment

The hydraulic breaker is equipped with a pressure relief

valve which secures the breaker. The operating pressure

of the machine (max 150bar (2176psi)) is checked and

adjusted by a pressure gauge while operating the hy-

draulic breaker.

n

If the operating pressure is more than 150bar

(2176psi) the pressure must be decreased. Reduce

the oil flow from the carrier until the pressure is down

to 150bar (2176psi). This adjustment is important to

ensure that the built in pressure relief valve in the

breaker does not open and leak oil back to the tank

and create heating problems.

n

If the operating pressure is between 130–150 bar

(1886-2176psi), normally no adjustment is needed.

n

If the carrier's oil flow is too low to retain an accept-

able operating pressure the restrictor in the breaker

needs to be changed. See flow diagrams in "Techni-

cal data" to choose the best restrictor for your appli-

cation.

Position the hydraulic breaker vertically towards solid

bedrock or similar to adjust the pressure using a pres-

sure gauge.

5.5 Water flushing

The hydraulic breaker is prepared for water flushing, this

function is to bind the dust when performing demolition

operations.

When connecting water flushing the plug in the front of

the breaker must be exchanged with a water nozzle. See

the Spare parts list for ordering a new water nozzle.

Use a ¼ in. hydraulic hose with a JIC connection as a

proper water hose. Contact your nearest authorised

workshop for further instructions.

NOTICE It is recommended to use water flushing to re-

duce the wear on the hydraulic breaker during tunnel

and dust-intensive applications.

5.6 Working tool

5.6.1 Selecting the right working tool

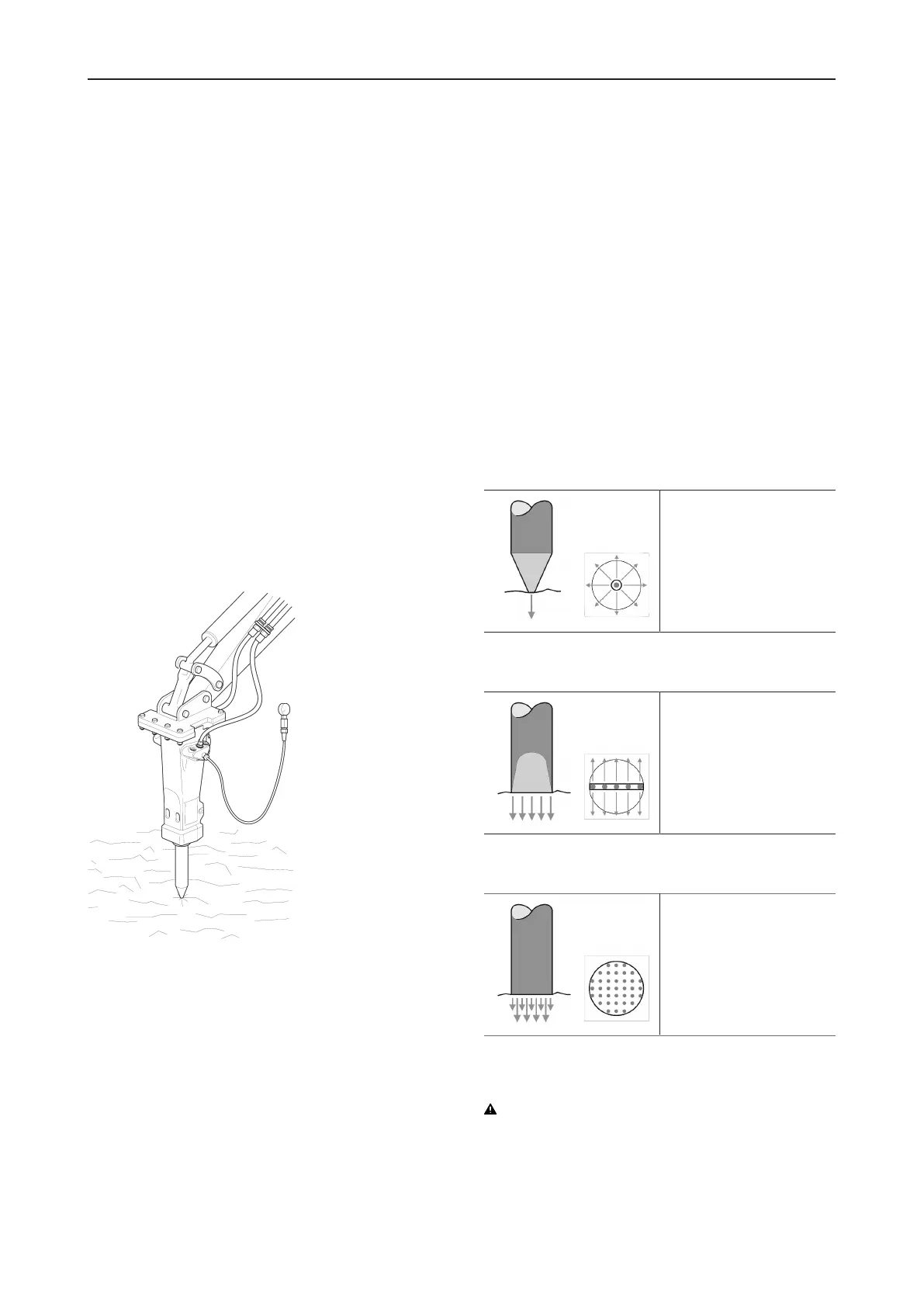

5.6.1.1 Conical moil point

• Very good penetra-

tion

• Regular spread of

wedge action

• No torsion effect

5.6.1.2 Chisels and spades

• Very good spread of

wedge action

• Good penetration

• Torsion effect

5.6.1.3 Blunt tool

• Very good energy ap-

plication

• Optimum breaking ef-

fect

• No torsion effect

5.6.2 Changing the working tool

WARNING Running engine

Changing the inserted tool or accessories while the car-

rier's engine is running can cause serious injury.

u Secure the carrier against involuntary activation.

Loading...

Loading...