Safety and operating instructions

20 © Construction Tools PC AB | 9800 0908 01 | 2023-05-12

Original Instructions

7 Maintenance

It is essential that regular maintenance is performed to

maintain the breakers maximum efficiency.

Equipment that is insufficiently maintained can be dan-

gerous for both the operator and persons near the

breaker. Make sure that regular maintenance routines

with lubrication are followed to keep the equipment safe

and efficient.

7.1 Cleaning

NOTICE Environmental damage due to polluted water

Hydraulic oil and chisel paste are environmentally harm-

ful and must not penetrate the ground or enter the water

table or water supplies.

u Collect the water used for cleaning if it has been con-

taminated by hydraulic oil and chisel paste.

u Dispose of the water in accordance with the applica-

ble regulations to avoid environmental hazards.

7.2 Every second hour

Regularly lubricate the working tool, the tool retainer and

the bushings.

7.2.1 Lubricating with a grease gun

WARNING Hot working tool during operation and

a period of time after use

u Avoid contact with the working tool.

WARNING Hot hydraulic breaker during operation

and a period of time after use

u Avoid contact with the hydraulic breaker.

CAUTION Skin eczema

Grease can cause eczema if it comes in contact with the

skin.

u Avoid getting grease on your hands. Wash thor-

oughly after contact.

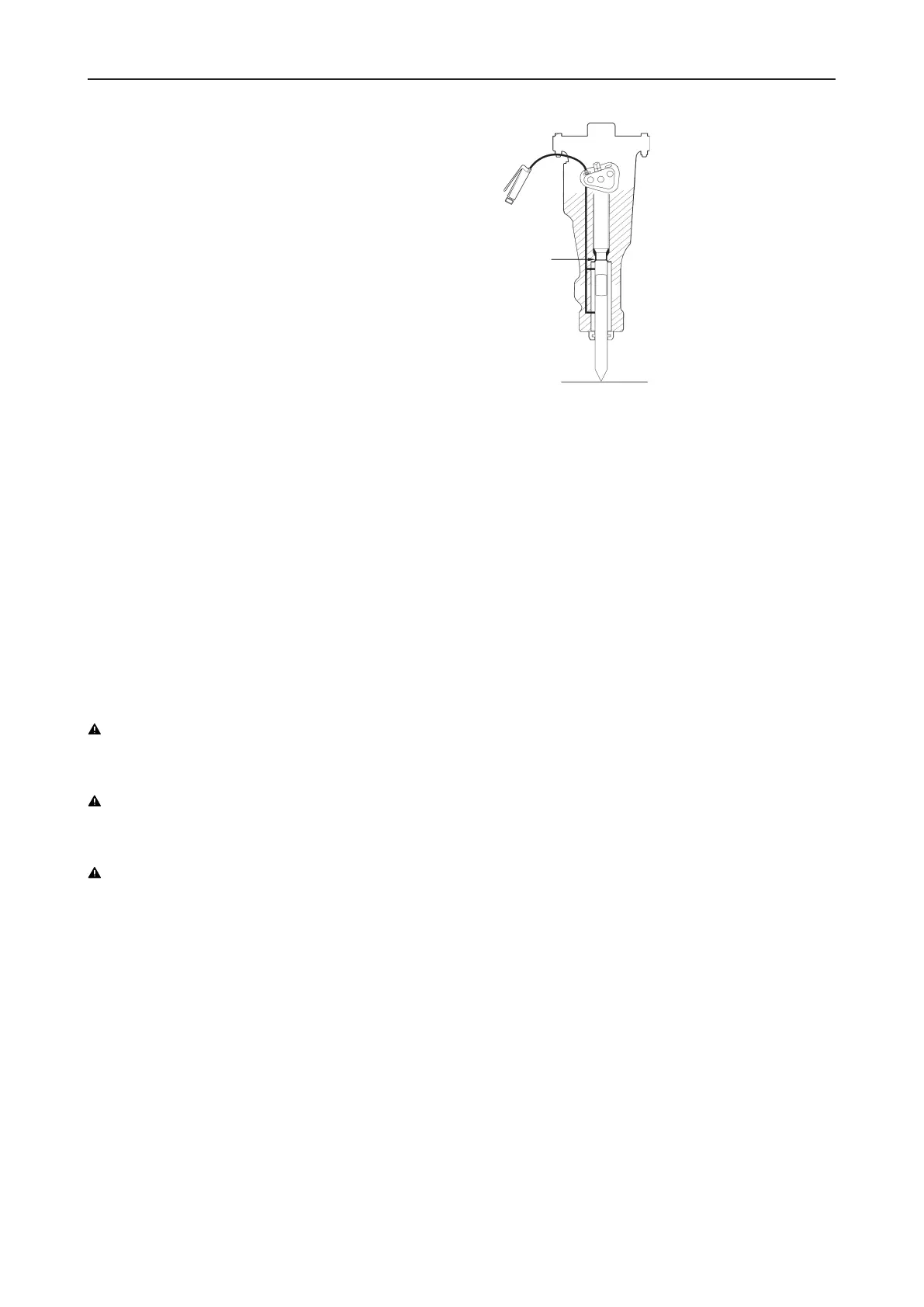

1.

Press the working tool all the way into the breaker up

to the stop(A). Otherwise the space between the top

of the working tool and the piston will be filled with

grease, and damage can occur to seals, piston, and

cylinder.

2.

Lubricate the working tool's shank plentifully during

all upward operations. The bushing and the working

tool must be lubricated so frequently that dirt cannot

penetrate into the hydraulic breaker.

When the working tool is exposed to high pressure and

high temperatures a standard type of grease will melt

and run. To avoid this always use Epiroc chisel paste.

7.2.2 Central lubrication system

We recommend Epiroc's central lubrication system.

When this system is fitted on the carrier, grease is

pumped continuously from a lubrication container on the

carrier to the hydraulic breaker when the hydraulic

breaker is activated. This increases the life of the tool

bushings and working tools considerably.

7.3 Every day

n

Check tool retainers and lock pins for damage,

change if necessary.

n

Check that hoses, couplings, and accumulator are in

a good condition, change if necessary.

n

Check that bolts and connections are free from dam-

age and properly tightened, change if damaged. See

tightening torques in the spare parts list.

n

Refill the central lubricating system.

7.4 Every week

n

Clean the hydraulic breaker carefully.

n

Check the wear bushing's wear and maximum inner

wear limits.

Loading...

Loading...