15

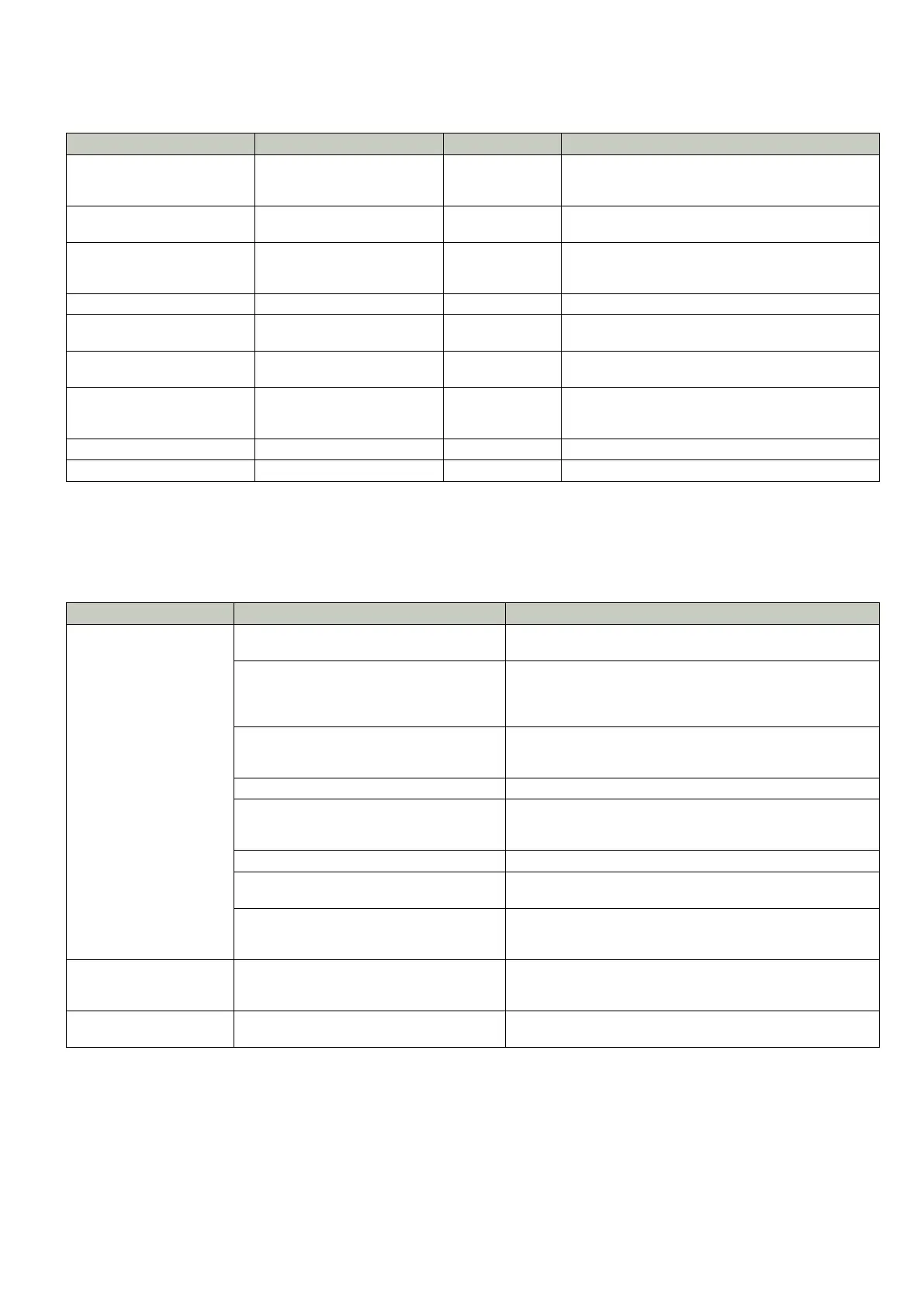

Wear limits

Component Wear limit Action Comments

Drill bit (diameter). Min. 6–10 mm (COP 34 4–7

mm) greater than the max.

diam. of the cylinder.

Fit new bit. Min. measurement at lower working pressures.

Max. measurement at higher working pressure.

Driver chuck (diameter). Never less than the diameter

of the cylinder.

Replace. Failure to replace in good time will cause severe

wear to hammer cylinder.

Cylinder (diameter). COP 44 – min. 89 mm

COP 54/54Qm – min. 111 mm

COP 64/64qm – min. 132 mm

Replace. Measure the diameter along the full length of the

cylinder, with the exception of the outermost 100

mm at each end. Risk of fracture.

Bit bushing (inside diameter). COP 64 max. 87,6 mm Replace. Measure the bit bushing at its waist.

Piston / Cylinder. Diametric clearance:

max. 0,20 mm

Replace worn

parts.

Outside diameter of piston should be measured at

the sealing surface of the piston.

Piston / Control tube. Diametric clearance:

max. 0,20 mm

Replace worn

parts.

Inside diam. of the piston against outside diam. of

the control tube.

Check valve. Valve seat worn or damaged. Replace worn or

damaged parts.

Tightness of check valve can be tested by pouring a

small amount of oil into the valve with the hammer

in vertical position.

Sleeve (flushing valve). Worn or damaged. Replace.

Buffer. Worn or damaged. Replace.

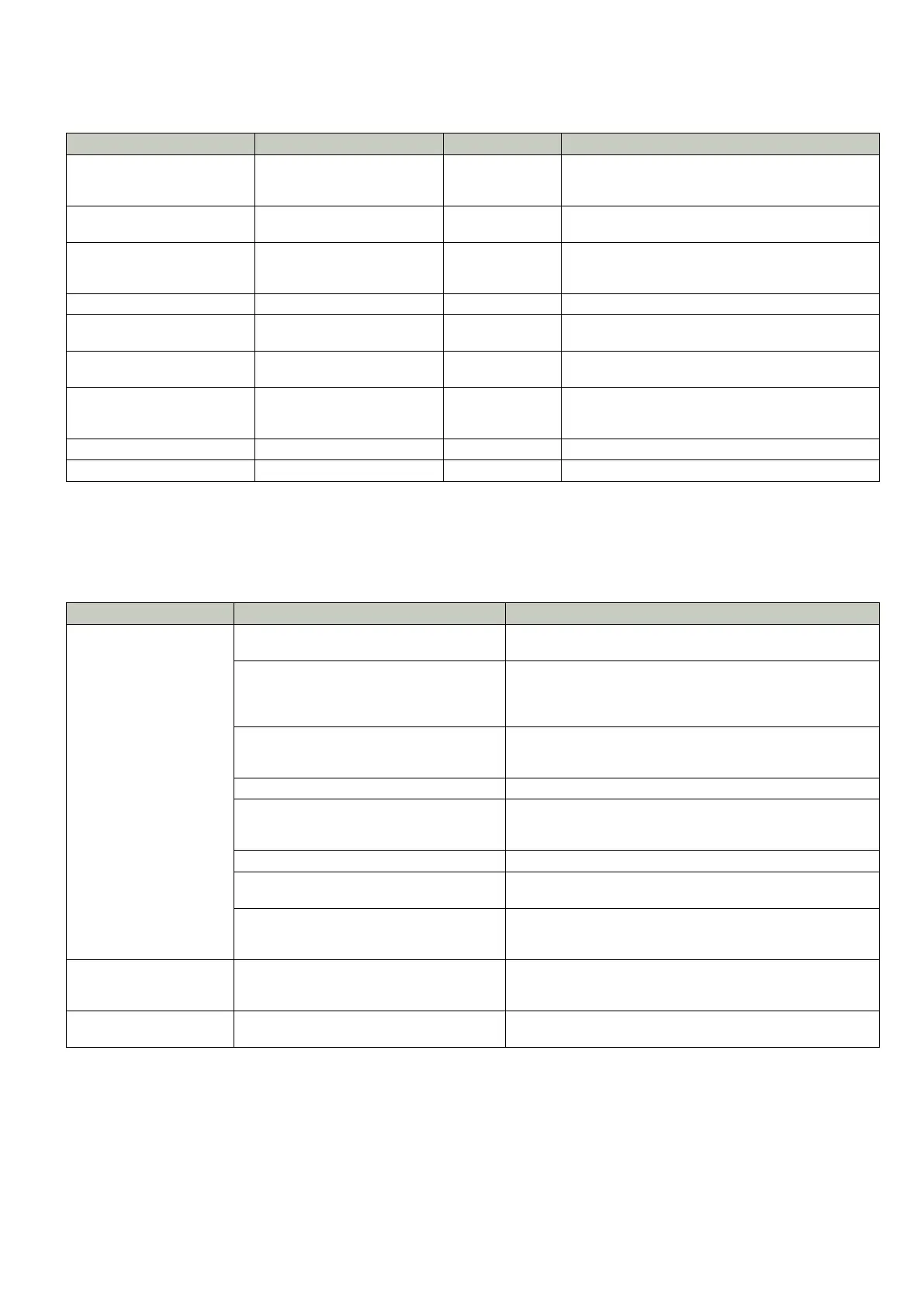

Trouble shooting

Fault Cause Remedy

Impact mechanism does

not operate, or works with

reduced effect.

Air supply throttled or blocked. Check the air pressure. Check that all air passages leading to

the hammer are open.

Oil is not reaching the impact mechanism

of the hammer. Poor or no lubrication,

causing increased wear, scoring or seizure.

Let operating air blow through rotation spindle on dry

plank or similar. After a few moments, plank surface should

become oily. Inspect lubricator. Top-up with oil if necessary

or increase lube oil dosage.

Too large clearance (wear) between the

piston and cylinder, or between piston and

control tube.

Disassemble the hammer and inspect the wear (see ”Wear

limits”). Replace worn parts.

Hammer clogged with dirt. Disassemble the hammer and wash all components.

Compression ring worn or damaged. Check clearance between top sub and cylinder. (See

”Checking the clearance between the top sub and cylinder”,

page 10) Replace worn or damaged compression ring.

Worn buffer rings in the cover. Disassemble the hammer and replace the buffer rings.

O-rings in bit bushing (COP 64) are worn or

damaged.

Disassemble the hammer and replace the O-rings.

Dirt enters the hammer when drilling in

water-bearing formation.

Make sure the check valve seals against the seat in the top

sub (see ”Dirt in hammer”, page 9). Remove the top sub and

replace check valve.

Lost drill bit and chuck Impact mechanism has been operated

without rotation to the right.

Fish out the lost equipment using a fishing tool. Remember

to always use right-hand rotation, both when drilling and

when lifting the drill string.

Excessive air

consumption

Flushing valve parts damaged.

Foot valve worn or damaged.

Disassemble and replace damaged parts, see page 7.

Replace foot valve, see page 12.

Overhauling

DTH hammers should be overhauled at suitable intervals depending on the drilling conditions and empirical service records. Since the

abrasiveness of the rock has a considerable bearing on the rate of wear, it will affect the overhauling intervals accordingly. Before the DTH

hammer is sent to an authorized Epiroc service workshop for overhauling, the joints at the top sub and driver chuck should be ”cracked” on

the rig.

Loading...

Loading...