5

Preparing to drill

Hose connection

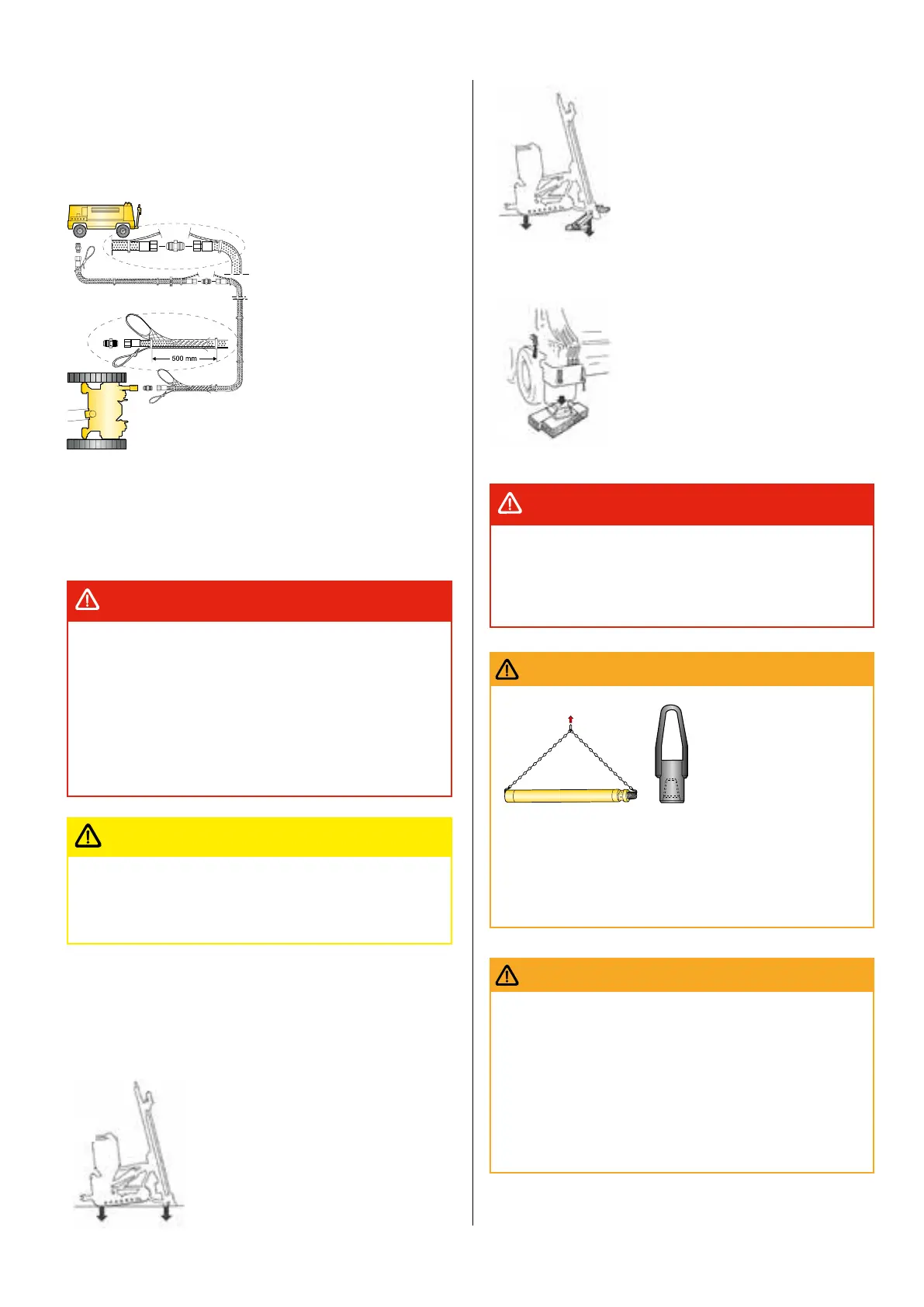

Connecting and securing the air hoses

For a compressed air system to

be efficient, reliable and

economic, there must be:

• sufficient compressed-air ca

-

pacity (volume and pressure);

• minimal pressure loss between

the compressor and the hammer;

• minimal air leakage between

couplings.

This can be realized by ensuring

that:

• the correct size of compressor

is selected;

• the correct hose size is used

between the compressor and the

hammer;

• there is no leakage in hose con

-

nections between the compres-

sor and hammer.

• Compressed-air hoses between the compressor and the

drill rig must be secured by means of an external or internal

safety wire, which must be fastened safely to the drill rig. If

the DTH hammer is to work at pressures above 10 bar (145

psi), any local regulations regarding air hoses and couplings

must be strictly observed.

• Always check that hoses, hose nipples and hose clamps

are not damaged, and that they are properly tightened and

secured.

DANGER

• Always check the condition of drill string components. Bent

or worn pipes can cause damage and excessive wear to the

hammer and rig.

CAUTION

Setting-up the rig

Before drilling with the DTH hammer, the rig must be set-up cor-

rectly in order to give stability and safety. If this is not done, the

effects of feed force and rotation torque can cause the rig to move.

This will have a negative effect on drilling, especially when drilling

deep, straight holes.

When setting up a drill wagon or crawler

drill rig, a stable three-point set-up must be

obtained, with the weight of the rig distrib-

uted between the base of the feed beam and

the two rear corners of the rig. It is of the

utmost importance that the rear loading

points are as far to the rear of the rig as

possible, with most of the rig weight being

loaded on to the base of the feed.

When drilling in soil or other non-consolidat-

ed formations, the weight of the rig must not

be loaded on to the feed near the mouth of

the hole, since this could easily cause the

hole to cave-in. Instead, the load should be

distributed some distance to either side of

the hole. Suitable support can be obtained

by placing a sturdy U-beam under the base

of the feed beam, and supporting the beam

on planks at both ends. A two inch (50 mm)

plank should then be placed inside the

U-beam to prevent mechanical chatter and

damage to the base of the feed beam.

If the rig is wheel-bound, it should be raised

off the ground completely using the jacks,

so that all wheels are clear of the ground.

• The rig must be set-up correctly in order to give stability

and safety. If this is not done, the effects of feed force and ro-

tation torque can cause the rig to move or even to overturn.

This can incur the risk of serious or fatal injury as well as

damage to the drill rig and equipment.

DANGER

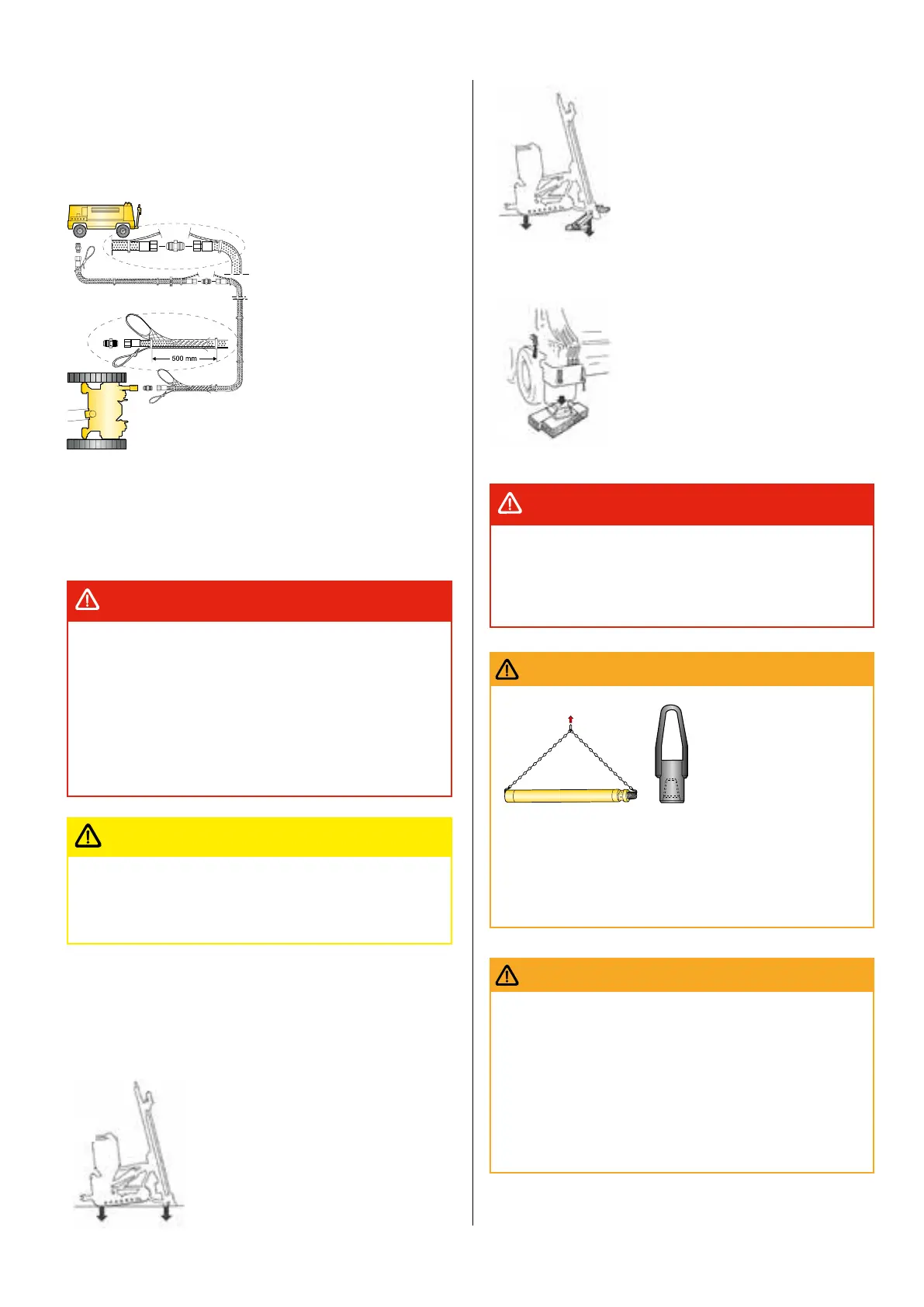

• Heavy lift. Take care when

handling the hammer. The

hammer and its internal

components are heavy and

difficult to handle, espe-

cially in the case of the

larger hammers.

When lifting using mechanical lifting equipment, sling the

hammer as shown in the fig. Alternatively, a lifting-eye cou-

pling can be screwed on to the top sub.

• Transportation. Do not let the hammer lie unsecured on a vehi-

cle or drill rig. Al ways secure the hammer for transportation.

WARNING

• Always wear goggles during drilling!

• The exhaust air from the hammer (and also from the top

sub if a unit for extra flushing is fitted) has a very high

velocity. Objects such as small stones, drill cuttings, sand,

earth and oil residue that are entrained in the flushing air

can cause serious injury to unprotected eyes. Pay special

attention to this danger during collaring, when a top sub with

extra flushing is in use, an when the hammer is fed through

the drill steel support or down into the hole.

WARNING

Loading...

Loading...