SHOP MANUAL

Paragraphs 82-88

Clean exterior surfaces with a brass

wire brush, soaking in an approved car-

bon solvent if necessary, to loosen hard

carbon deposits. Rinse parts in clean

diesel fuel or calibrating oil immediately

after cleaning to neutralize the solvent

and prevent etching of polished sur-

faces.

Clean nozzle spray orifice hole using

1.0 mm (0,040 inch) wire in a pin vise.

Scrape carbon from pressure chamber

using hooked scraper. Clean valve seat

using brass scraper.

Reclean all parts by rinsing thoroughly

in clean diesel fuel or calibrating oil and

assemble while parts are immersed in

cleaning fluid. Make sure adjusting shim

pack is intact. Tighten nozzle retaining

nut (3) to a torque of 61-75 N-m (45-55

ft.-lbs.).

Do not overtighten, distortion

may cause valve to stick and no amount

of overtightening can stop a leak caused

by scratches or dirt. Retest assembled

injector as previously outlined.

GLOW PLUGS

All Models

82.

Glow plugs are parallel connected

with each glow plug grounding through

mounting threads. Start switch is pro-

vided with a "HEAT" position which can

be used to energize the glow plugs for

faster warm up. If "COLD START AID"

indicator light fails to glow when start

switch is held in "HEAT" position an ap-

propriate length of time (approximately

30 seconds), check for loose connections

at switch, indicator lamp, glow plug con-

nections and ground. A test lamp can be

used at glow plug connection to check

for current to glow plug.

COOLING SYSTEM

All models use a pressurized cooling

system which raises coolant boiling

point. An impeller type centrifugal

pump is used to provide forced circula-

tion, A thermostat is used to stabilize

operating temperature.

RADIATOR

All Models

85.

Radiator cap pressure valve is set

to open at 90 kPa (13 psi) on all models.

It is recommended that a 50/50 mix of

ethylene glycol base antifreeze and

water be used for coolant. Refer to

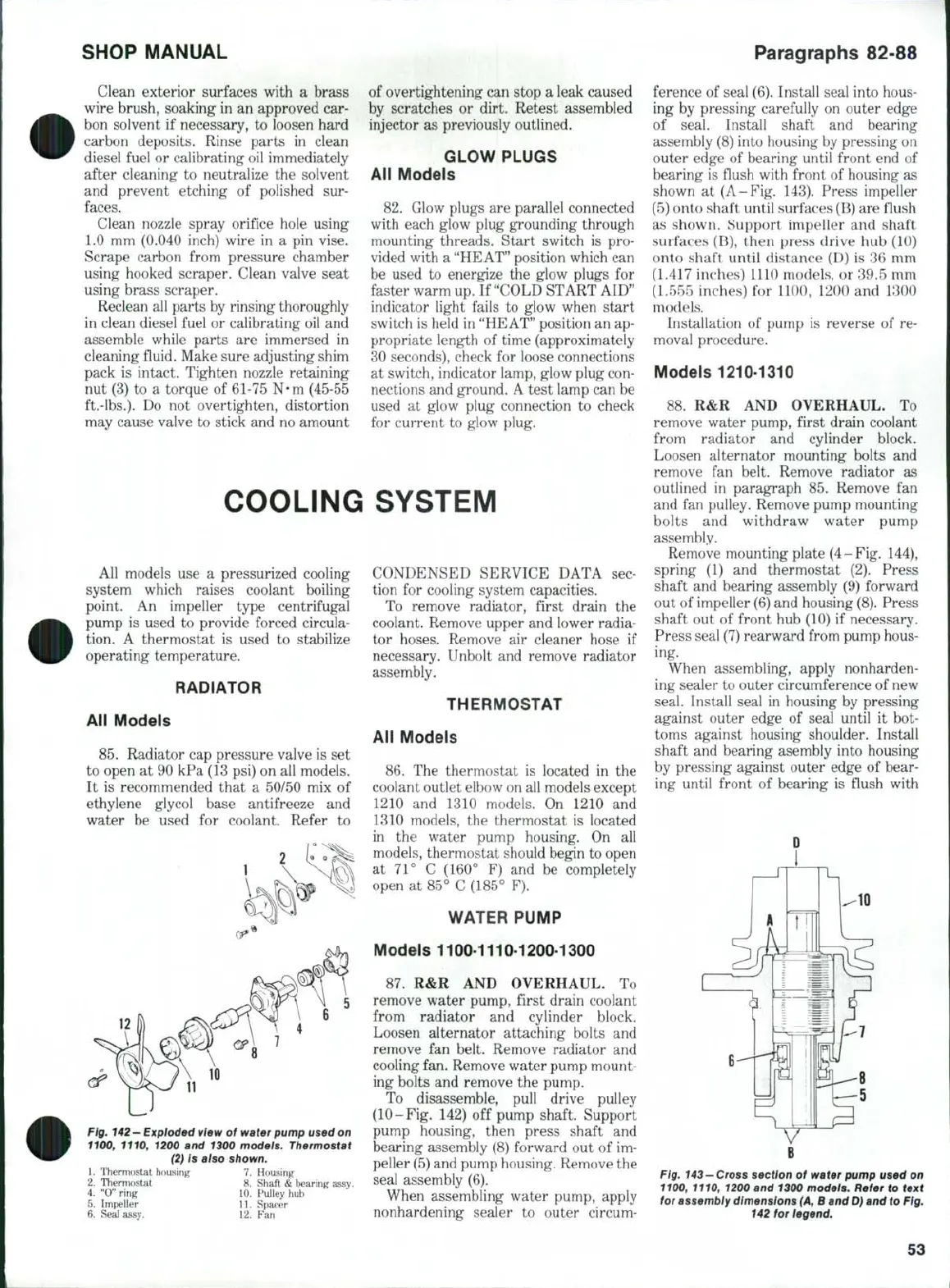

2

FIQ.

142—

Exploded view of water pump used on

1100, 1110, 1200 and 1300 modeis. Thermostat

(2) is aiso shown.

1,

Thermostat housing

2.

Thermostat

4.

"0" ring

5.

Impeller

6. Seal assy.

7.

8.

10.

11,

12.

Housing

Shaft

&

bearing assy

Pulley huh

Spacer

Fan

CONDENSED SERVICE DATA sec-

tion for cooling system capacities.

To remove radiator, first drain the

coolant. Remove upper and lower radia-

tor hoses. Remove air cleaner hose if

necessary. Unbolt and remove radiator

assembly.

THERMOSTAT

All Models

86.

The thermostat is located in the

coolant outlet elbow on all models except

1210 and 1310 models. On 1210 and

1310 models, the thermostat is located

in the water pump housing. On all

models, thermostat should begin to open

at 7r C (160° F) and be completely

open at

85"*

C (185° F),

WATER PUMP

Models 1100-1110-1200-1300

87.

R&R AND OVERHAUL. To

remove water pump, first drain coolant

from radiator and cylinder block.

Loosen alternator attaching bolts and

remove fan belt. Remove radiator and

cooling fan. Remove water pump mount-

ing bolts and remove the pump.

To disassemble, pull drive pulley

(10-Fig. 142) off pump shaft. Support

pump housing, then press shaft and

bearing assembly (8) forward out of im-

peller

(5)

and pump housing. Remove the

seal assembly (6).

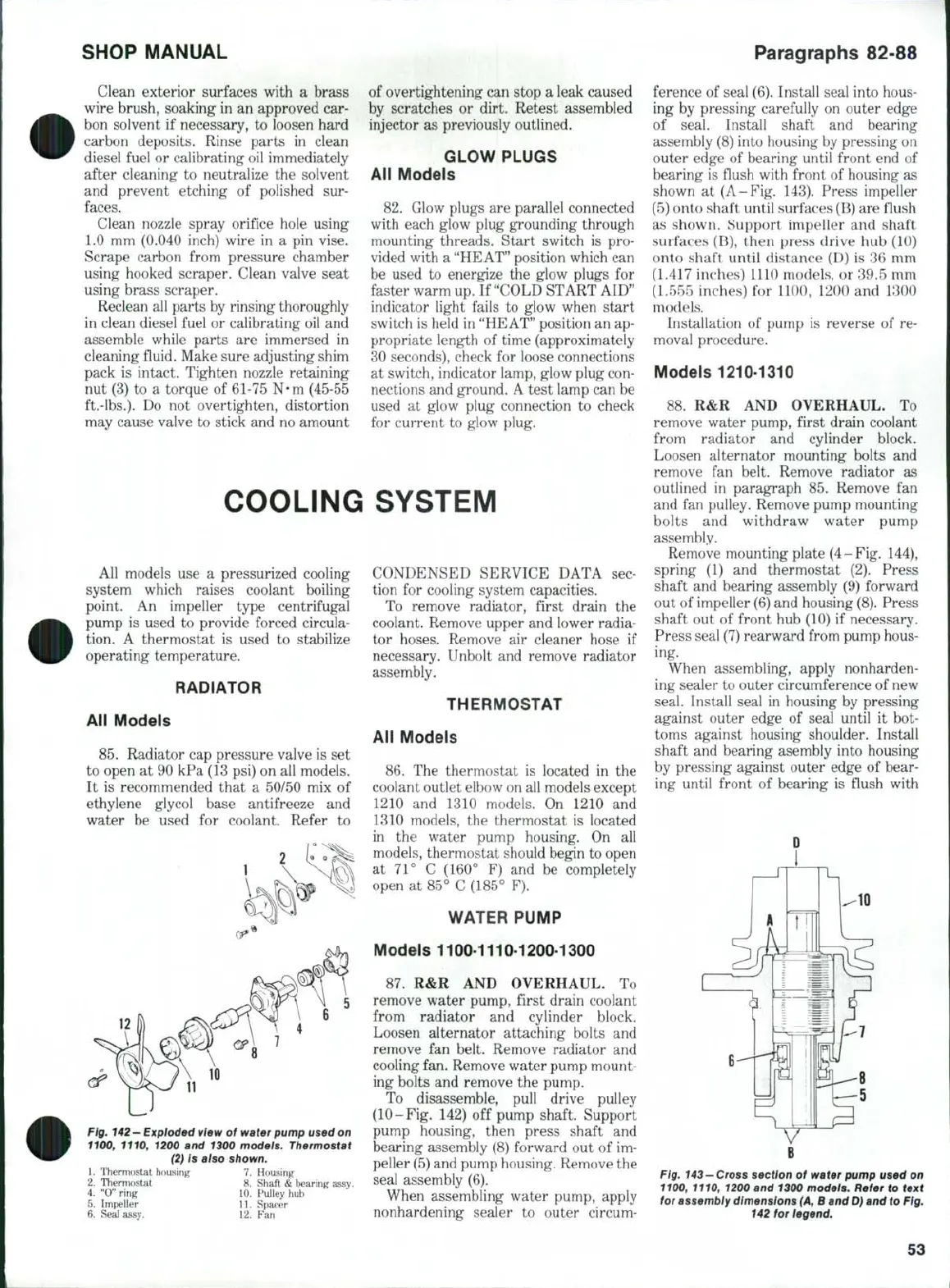

When assembling water pump, apply

nonhardening sealer to outer circum-

ference of seal (6). Install seal into hous-

ing by pressing carefully on outer edge

of seal. Install shaft and bearing

assembly (8) into housing by pressing on

outer edge of bearing until front end of

bearing is flush with front of housing as

shown at (A-Fig. 143). Press impeller

(5) onto shaft until surfaces (B) are flush

as shown. Support impeller and shaft

surfaces (B), then press drive hub (10)

onto shaft until distance (D) is 36 mm

(1.417 inches) UK) models, or 39.5 mm

(L555 inches) for 1100, 1200 and 1300

models.

Installation of pump is reverse of re-

moval procedure.

Models 1210-1310

88.

R&R AND OVERHAUL. To

remove water pump, first drain coolant

from radiator and cylinder block.

Loosen alternator mounting bolts and

remove fan belt. Remove radiator as

outlined in paragraph 85. Remove fan

and fan pulley. Remove pump mounting

bolts and withdraw water pump

assembly.

Remove mounting plate (4-Fig. 144),

spring (1) and thermostat (2). Press

shaft and bearing assembly (9) forward

out of impeller (6) and housing

(8).

Press

shaft out of front hub (10) if necessary.

Press seal (7) rearward from pump hous-

ing.

When assembling, apply nonharden-

ing sealer to outer circumference of new

seal. Install seal in housing by pressing

against outer edge of seal until it bot-

toms against housing shoulder. Install

shaft and bearing asembly into housing

by pressing against outer edge of bear-

ing until front of bearing is flush with

10

Fig.

143—

Cross

section of water pump used on

1100, 1110, 1200 and 1300 models. Refer to text

for assembiy dimensions

(A,

B and D) and to Fig.

142 for legend.

53

Loading...

Loading...