SHOP MANUAL

Paragraph 32

lead pencil. Install valve and rotate

valve against seat while applying light

Tessure against the valve. Seat contact

lint should be in center of valve face

and seat width should be within speci-

fied limits. If necessary, use a 30° stone

to lower seat contact point and use a 60°

stone to raise seat contact point. Both

stones will narrow the seat width. Check

for correct recession (R) of valve head

below machined surface of cylinder

head. Renewable valve seat inserts are

available on 1110, 1510, 1710, 1900,

1910 and 2110 models.

Measure valve stem diameter and

valve guide bore to determine stem to

guide clearance. Renewable valve guides

are used on 1910 and 2110 models. On

all other models, cylinder head must be

renewed if guides are excessively worn.

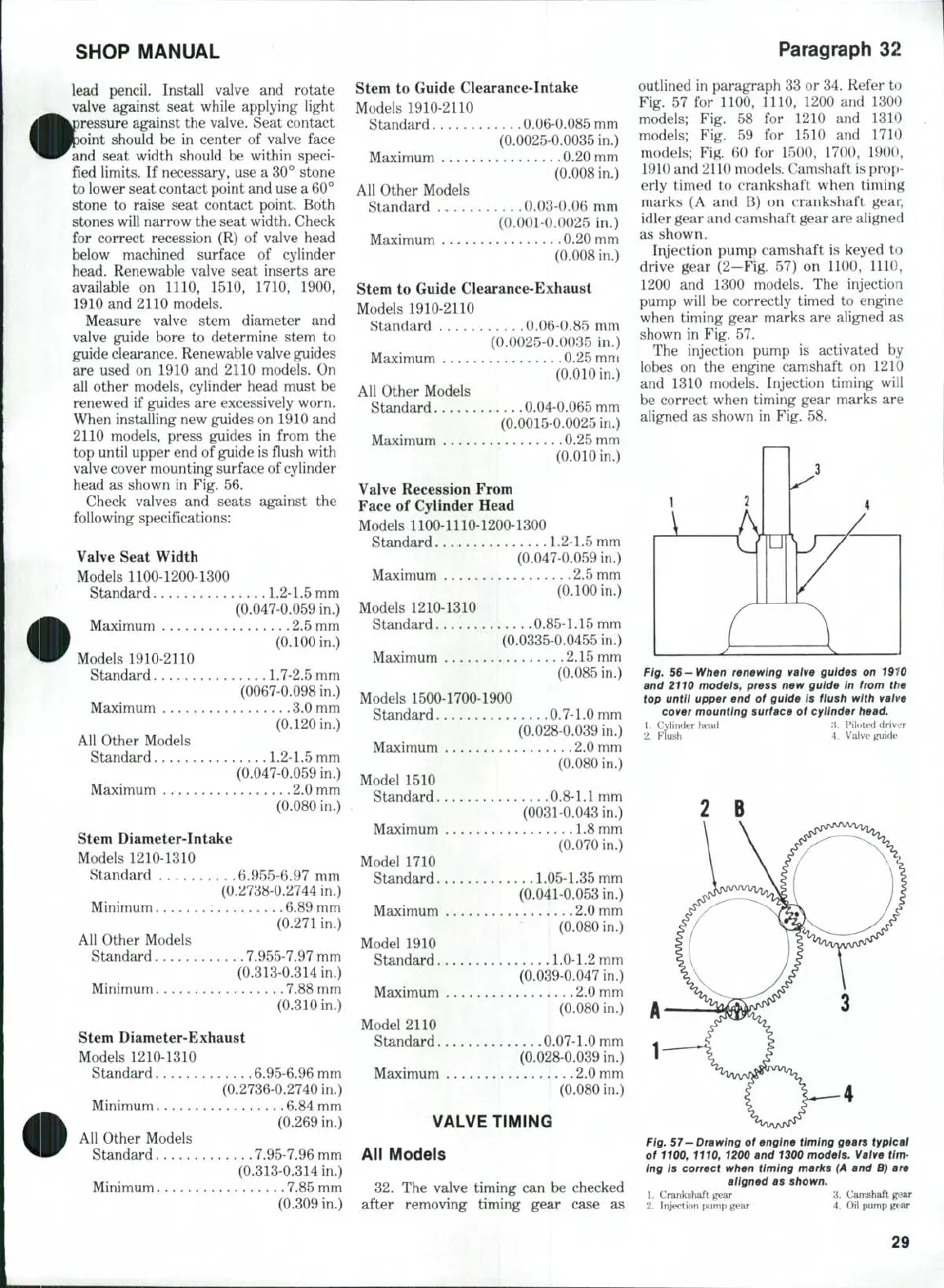

When installing new guides on 1910 and

2110 models, press guides in from the

top until upper end of guide is flush with

valve cover mounting surface of cylinder

head as shown in Fig. 56.

Check valves and seats against the

following specifications:

Valve Seat Width

Models 1100-1200-1300

Standard

1,2-1.5

mm

(0.047-0.059 in.)

Maximum 2.5 mm

(0.100 in.)

Models 1910-2110

Standard

1.7-2.5

mm

(0067-0.098 in.)

Maximum 3.0 mm

(0,120 in.)

All Other Models

Standard

1,2-1.5

mm

(0.047-0.059 in.)

Maximum 2.0 mm

(0,080 in.)

Stem Diameter-Intake

Models 1210-1310

Standard 6.955-6.97 mm

(0.2738-0.2744 in.)

Minimum ; 6.89 mm

(0.271 in.)

All Other Models

Standard 7,955-7,97 mm

(0.313-0.314 in.)

Minimum 7.88 mm

(0.310 in.)

Stem Diameter-Exhaust

Models 1210-1310

Standard 6.95-6.96 mm

(0,2736-0.2740 in.)

Minimum 6.84 mm

(0.269 in.)

All Other Models

Standard 7.95-7.96 mm

(0.313-0.314 in.)

Minimum 7.85 mm

(0.309 in.)

Stem to Guide Clearance-Intake

Models 1910-2110

Standard 0.06-0.085 mm

(0.0025-0,0035 in.)

Maximum 0.20 mm

(0.008 in.)

All Other Models

Standard 0.03-0.06 mm

(0.001-0.0025 in.)

Maximum 0.20 mm

(0.008 in.)

Stem to Guide Clearance-Exhaust

Models 1910-2110

Standard 0.06-0.85 mm

(0.0025-0.0035 in.)

Maximum 0.25 mm

(0.010 in.)

All Other Models

Standard 0.04-0.065 mm

(0.0015-0,0025 in.)

Maximum 0.25 mm

(0,010 in.)

Valve Recession From

Face of Cylinder Head

Models 1100-1110-1200-1300

Standard

1.2-1.5

mm

(0.047-0,059 in.)

Maximum 2.5 mm

(0.100 in.)

Models 1210-1310

Standard 0.85-1.15 mm

(0.0335-0.0455 in.)

Maximum 2.15 mm

(0.085 in,)

Models 1500-1700-1900

Standard

0,7-1.0

mm

(0,028-0.039 in.)

Maximum 2.0 mm

(0.080 in.)

Model 1510

Standard

0.8-1.1

mm

(0031-0.043 in.)

Maximum 1.8 mm

(0,070 in,)

Model 1710

Standard

1,05-1,35

mm

(0.041-0.053 in.)

Maximum 2.0 mm

(0,080 in.)

Model 1910

Standard

1.0-1.2

mm

(0.039-0.047 in.)

Maximum 2.0 mm

(0,080 in.)

Model 2110

Standard. 0.07-l.Omm

(0.028-0.039 in.)

Maximum 2,0 mm

(0,080 in.)

VALVE TIMING

All Models

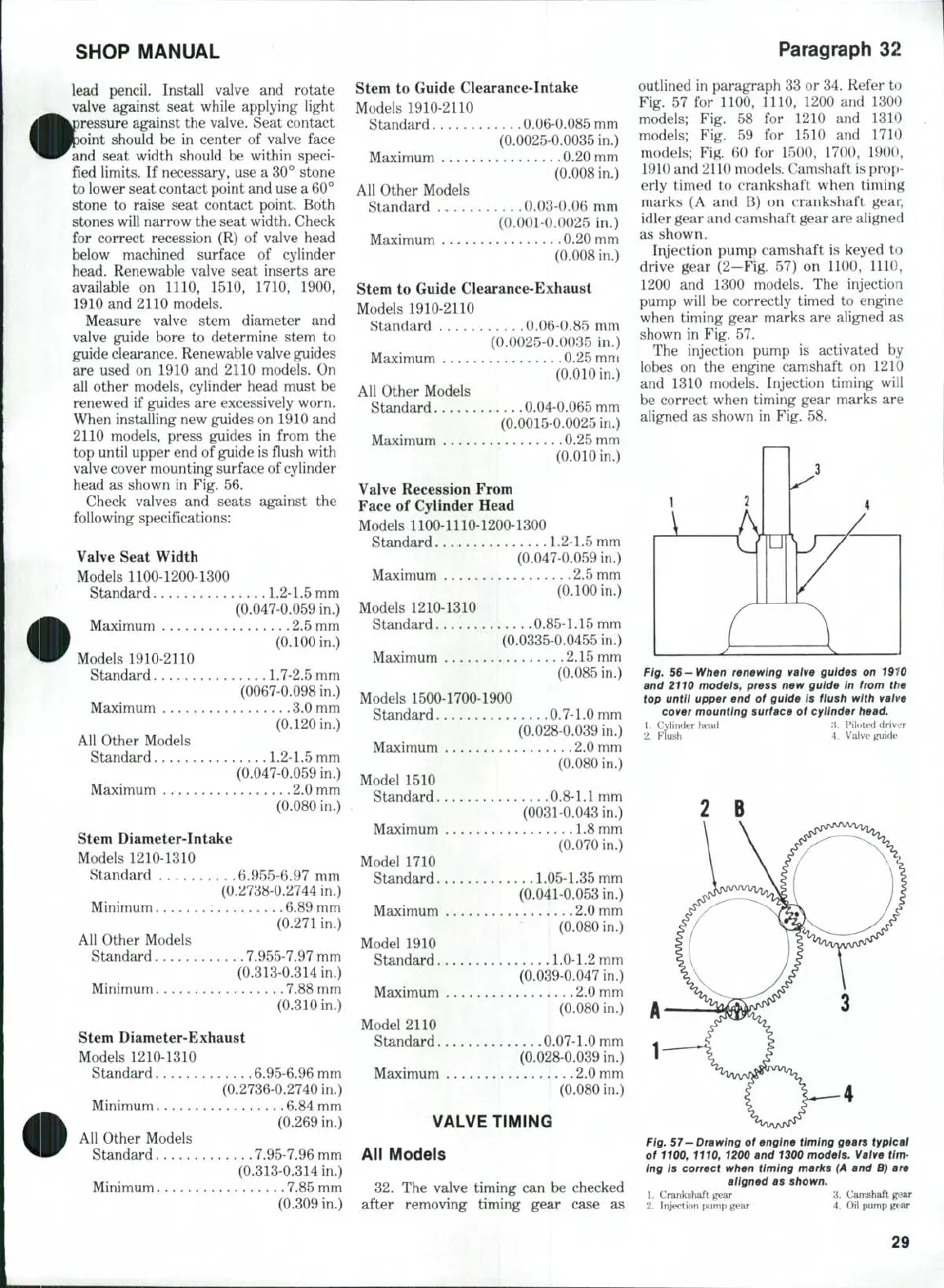

32,

The valve timing can be checked

after removing timing gear case as

outlined in paragraph 33 or 34, Refer to

Fig. 57 for 1100, 1110, 1200 and 1300

models; Fig, 58 for 1210 and 1310

models; Fig. 59 for 1510 and 1710

models; Fig. 60 for 1500, 1700, 1900,

1910 and 2110 models. Camshaft is prop-

erly timed to crankshaft when timing

marks (A and B) on crankshaft gear,

idler gear and camshaft gear are aligned

as shown.

Injection pump camshaft is keyed to

drive gear (2-Fig. 57) on 1100, 1110,

1200 and 1300 models. The injection

pump will be correctly timed to engine

when timing gear marks are aligned as

shown in Fig. 57.

The injection pump is activated by

lobes on the engine camshaft on 1210

and 1310 models. Injection timing will

be correct when timing gear marks are

aligned as shown in Fig. 58.

Fig. 56—When renewing vaive guides on 1910

and 2110 models, press new guide in from the

top until upper end of guide is fiush with vaive

cover mounting surface of cyiinder

head.

1.

Cylinder head A. Fil(>te<l driver

2.

Flush 4. Valve Kuide

Fig.

57—Drawing

of engine timing gears typical

of

1100,

1110, 1200 and 1300 models. Valve tim-

ing is correct when timing marks

(A

and

B)

are

aligned as shown.

1.

Crankshaft gear 3. Camshaft gear

2.

Injection pump gear 4. Oil pump gtar

29

Loading...

Loading...