SHOP MANUAL

Paragraph

4

Fig.

5

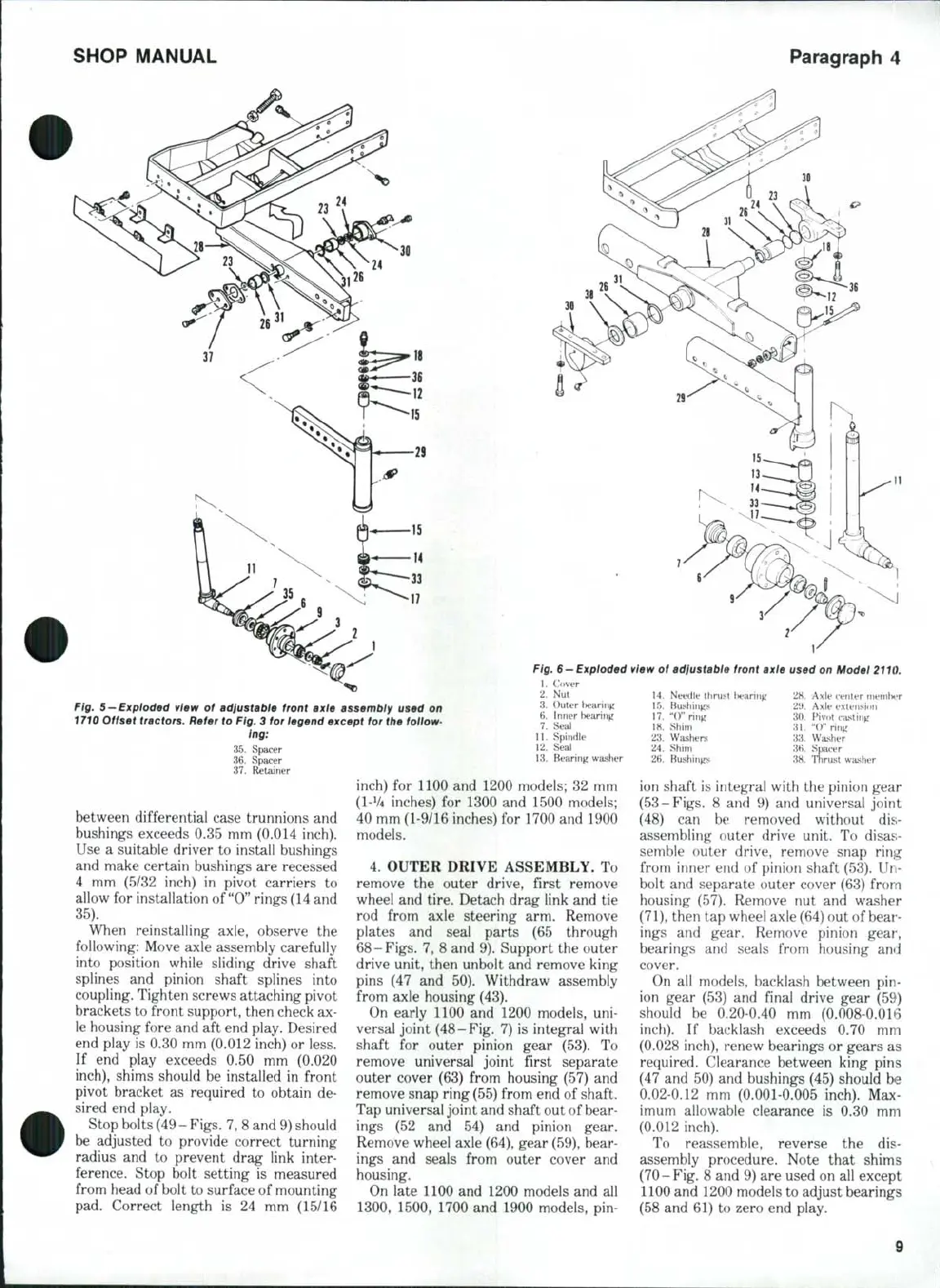

- Exploded view of adiustabie front axie assembiy used on

1710 Offset tractors. Refer to

Fig.

3 for iegend except for the follow-

ing:

35.

Spacer

36.

Spacer

37.

Retainer

inch)

for

1100

and

1200 models;

82

mm

(I-V4 inches)

for

1300

and

1500 models;

between differential case trunnions and

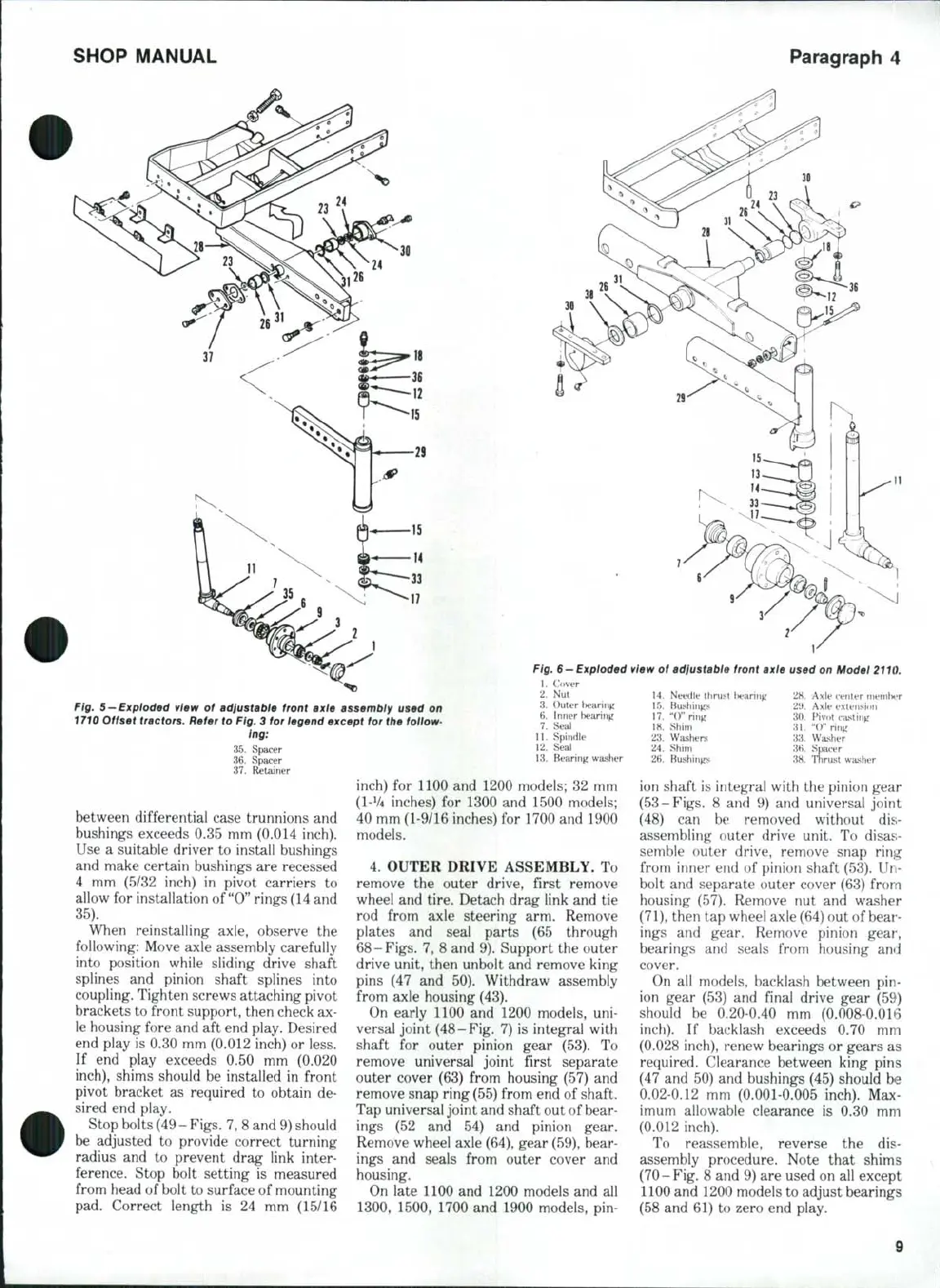

Fig.

6

—Expioded

view of adiustable front axle used on Model 2110.

1.

Cover

2.

Nut 14.

Needle thrust l)earirig

28.

Axle tenter ?nemU?r

3.

Outer tearing

15.

Bushings

21>.

Axle extension

6. Injier hearing

17. "0"

ring

30.

Pivot casting

7.

Seal

18.

Shim

31. "()"

ring

11.

Spindle

23.

Washers

33.

Washer

12.

Seal

24.

Shim

3fi.

Spacer

13.

Bearing washer

2H.

Bushings

38.

Thrust washer

bushings exceeds 0.35 mm (0.014 inch).

Use

a

suitable driver

to

install bushings

and make certain bushings are recessed

4

mm (5/32

inch)

in

pivot carriers

to

allow

for

installation of

"0"

rings (14 and

35).

When reinstalling axle, observe

the

following: Move axle assembly carefully

into position while sliding drive shaft

splines

and

pinion shaft splines into

coupling. Tighten screws attaching pivot

brackets to front support, then check ax-

le housing fore and

aft

end play. Desired

end play

is

0.30 mm (0.012 inch)

or

less.

If

end

play exceeds

0.50 mm

(0.020

inch),

shims should

be

installed

in

front

pivot bracket

as

required

to

obtain

de-

sired end play.

Stop bolts

(49

-

Figs.

7, 8 and 9) should

be adjusted

to

provide correct turning

radius

and to

prevent drag link inter-

ference. Stop bolt setting

is

measured

from head of bolt to surface

of

mounting

pad. Correct length

is 24 mm

(15/16

40 mm (1-9/16 inches)

for

1700 and 1900

models.

4.

OUTER DRIVE ASSEMBLY.

To

remove

the

outer drive, first remove

wheel

and

tire. Detach drag link and

tie

rod from axle steering

arm.

Remove

plates

and

seal parts

(65

through

68-Figs.

7, 8

and 9). Support the outer

drive unit, then unbolt and remove king

pins

(47 and 50).

Withdraw assembly

from axle housing (43).

On early 1100

and

1200 models,

uni-

versal joint (48-Fig. 7)

is

integral with

shaft

for

outer pinion gear

(53). To

remove universal joint first separate

outer cover (63) from housing (57)

and

remove snap ring (55) from end

of

shaft.

Tap universal joint and shaft out of bear-

ings

(52 and 54) and

pinion gear.

Remove wheel axle (64), gear (59), bear-

ings

and

seals from outer cover

and

housing.

On late 1100 and 1200 models

and all

1300,

1500, 1700

and

1900 models,

pin-

ion shaft

is

integral with the pinion gear

(53-Figs.

8 and 9) and

universal joint

(48)

can be

removed without

dis-

assembling outer drive unit.

To

disas-

semble outer drive, remove snap ring

from inner end

of

pinion shaft (53).

Un-

bolt

and

separate outer cover (63) from

housing (57). Remove

nut and

washer

(71),

then tap wheel axle (64) out of bear-

ings

and

gear. Remove pinion gear,

bearings

and

seals from housing

and

cover.

On

all

models, backlash between

pin-

ion gear

(53) and

final drive gear

(59)

should

be

0.20-0.40

mm

(0.008-0.016

inch).

If

backlash exceeds

0.70 mm

(0.028 inch), renew bearings

or

gears

as

required. Clearance between king pins

(47

and

50)

and

bushings (45) should

be

0,02-0.12

mm

(0.001-0.005 inch).

Max-

imum allowable clearance

is 0.30 mm

(0.012 inch).

To reassemble, reverse

the dis-

assembly procedure. Note that shims

(70-Fig.

8

and 9) are used on all except

1100 and 1200 models to adjust bearings

(58 and 61)

to

zero end play.

9

Loading...

Loading...