Paragraphs 89-91

FORD

front of housing as shown at (A-Fig.

145).

Press impeller onto shaft until end

of shaft is flush with rear of impeller (B).

Support impeller and shaft surfaces (B),

then press hub onto shaft until flush

with front of shaft as shown at (C).

Installation of pump is reverse of

removal.

Models 1500-1510-1700-1710-

1900-1910-2110

89,

R&R AND OVERHAUL. To

remove water pump, first drain coolant

from radiator and cylinder block. Re-

move radiator as outlined in paragraph

85.

Loosen alternator mounting bolts,

then remove fan belt and fan. Remove

pump mounting bolts and remove water

pump assembly.

Remove mounting plate (3-Fig. 146).

Remove set screw (9) from housing.

Press shaft and bearing assembly

(8)

for-

ward out of impeller (5) and housing.

Press seal (6) rearward out of housing.

Press pump shaft out of pulley (10).

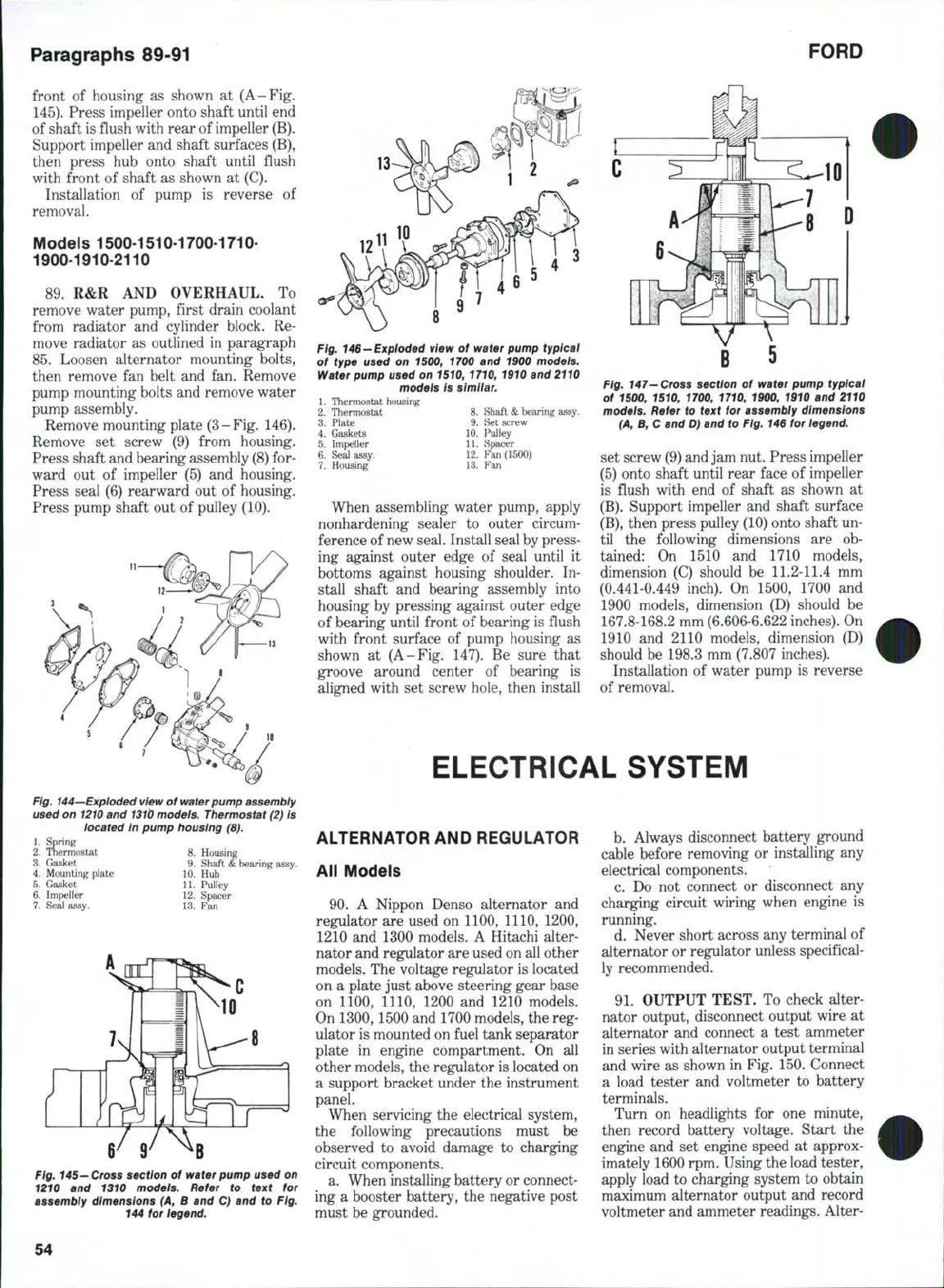

Fig.

144—Exploded

view of water pump assembiy

used on

1210

and

1310

modeis. Thermostat (2) is

located in pump housing (8).

1.

Spring

2.

Thermostat

3.

Gasket

4.

Mounting plate

5.

Gasket

6. Impeller

7. Seal assy.

8. Housing

9. Shaft

&

bearing assy.

10.

Hub

11.

Pulley

12.

Spacer

13.

Fan

B

Fig,

145 —Cross

section of water pump used on

1210 and 1310 modeis. Refer to text for

assembly dimensions (A, B and C) and to Fig,

144 for iegend.

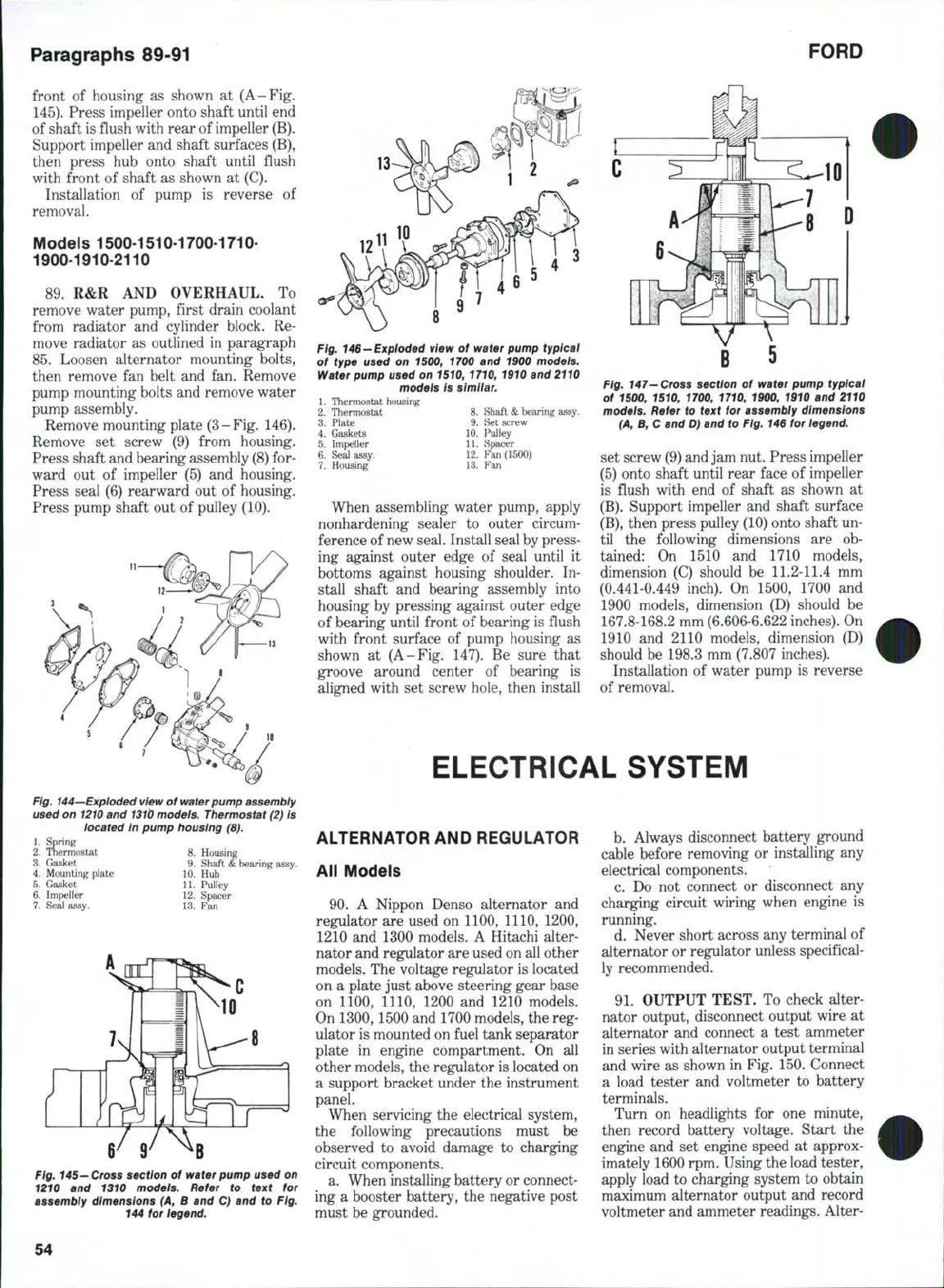

Fig, 146-Exploded view of water pump typicai

of type used on 1500, 1700 and 1900 modeis.

Water pump used on 1510, 1710, 1910 and 2110

models is

simiiar.

1.

Thermostat housing

2.

Thermostat 8. Shaft

&

bearing assy.

3.

Plate 9. Set screw

4.

Gaskets 10. Puliey

5.

Impeller 11. Sfwicer

6. Seal assy. 12. Fan (1500)

7.

Housing 13. ?"an

When assembling water pump, apply

nonhardening sealer to outer circum-

ference of new seal. Install seal by press-

ing against outer edge of seal until it

bottoms against housing shoulder. In-

stall shaft and bearing assembly into

housing by pressing against outer edge

of bearing until front of bearing is flush

with front surface of pump housing as

shown at (A-Fig. 147). Be sure that

groove around center of bearing is

aligned with set screw hole, then install

B

5

Fig, 147-

Cross

section of water pump typicai

of 1500, 1510, 1700, 1710, 1900, 1910 and 2110

modeis. Refer to text for assembly dimensions

(A,

B, C and D) and to Fig, 146 for iegend,

set screw (9) and jam nut. Press impeller

(5) onto shaft until rear face of impeller

is flush with end of shaft as shown at

(B).

Support impeller and shaft surface

(B),

then press pulley (10) onto shaft un-

til the following dimensions are ob-

tained: On 1510 and 1710 models,

dimension (C) should be 11.2-11.4 mm

(0.441-0.449 inch). On 1500, 1700 and

1900 models, dimension (D) should be

167.8-168.2 mm (6.606-6.622 inches). On

1910 and 2110 models, dimension (D)

should be 198,3 mm (7.807 inches).

Installation of water pump is reverse

of removal.

ELECTRICAL SYSTEM

ALTERNATOR AND REGULATOR

All Models

90.

A Nippon Denso alternator and

regulator are used on 1100, 1110, 1200,

1210 and 1300 models. A Hitachi alter-

nator and regulator are used on all other

models. The voltage regulator is located

on a plate just above steering gear base

on 1100, 1110, 1200 and 1210 models.

On 1300,1500 and 1700 models, the reg-

ulator is mounted on fuel tank separator

plate in engine compartment. On all

other models, the regulator is located on

a support bracket under the instrument

panel.

When servicing the electrical system,

the following precautions must be

observed to avoid damage to charging

circuit components.

a. When installing battery or connect-

ing a booster battery, the negative post

must be grounded.

b.

Always disconnect battery ground

cable before removing or installing any

electrical components.

c. Do not connect or disconnect any

charging circuit wiring when engine is

running,

d. Never short across any terminal of

alternator or regulator unless specifical-

ly recommended.

91.

OUTPUT TEST. To check alter-

nator output, disconnect output wire at

alternator and connect a test ammeter

in series with alternator output terminal

and wire as shown in Fig. 150, Connect

a load tester and voltmeter to battery

terminals.

Turn on headlights for one minute,

then record battery voltage. Start the

engine and set engine speed at approx-

imately 1600 rpm. Using the load tester,

apply load to charging system to obtain

maximum alternator output and record

voltmeter and ammeter readings. Alter-

54

Loading...

Loading...