Paragraphs 2-3

FORD

Axle end play should not exceed 0.20

mm (0.008 inch). If end play is excessive,

renew thrust washers (23) and/or add

shims (24) as required.

When renewing spindle bushings (15),

the top bushing should be pressed into

bore until bushing is 4.7 mm (3/16 inch)

below top surface of axle on models

equipped with an "0" ring (17-Figs, 1

and 2) at top of spindle (11). On models

equipped with a lip type seal (12-Figs.

3,

4, 5 and 6) at top of spindle, top

bushing should be pressed into bore until

top of bushing is 7 mm (9/32 inch) below

top surface of axle. Install seal with lip

facing upward.

Front wheel bearings should be re-

moved, cleaned, inspected, renewed if

damaged and packed with a good quality

No.

2 EP lithium base grease after each

600 hours of operation. Tighten wheel

bearing retaining nut (2) until slight

drag is noticed while rotating wheel hub,

then loosen nut to first castellation and

install cotter pin.

FRONT AXLE

(FOUR WHEEL DRIVE)

2.

The front axle of four wheel drive

models includes the differential as-

sembly, axle housings, drive shafts,

universal joints and final drives. Refer

to appropriate paragraphs 3 through 12

for service to components.

Tie rod length should be adjusted to

provide front wheel toe-in of 0-5 mm

(0-3/16 inch) on all models.

Models 1100-1200-1300-1500-1700

-1900 So Equipped

3.

REMOVE AND REINSTALL. To

remove the complete front drive axle as-

sembly, first raise front of tractor and

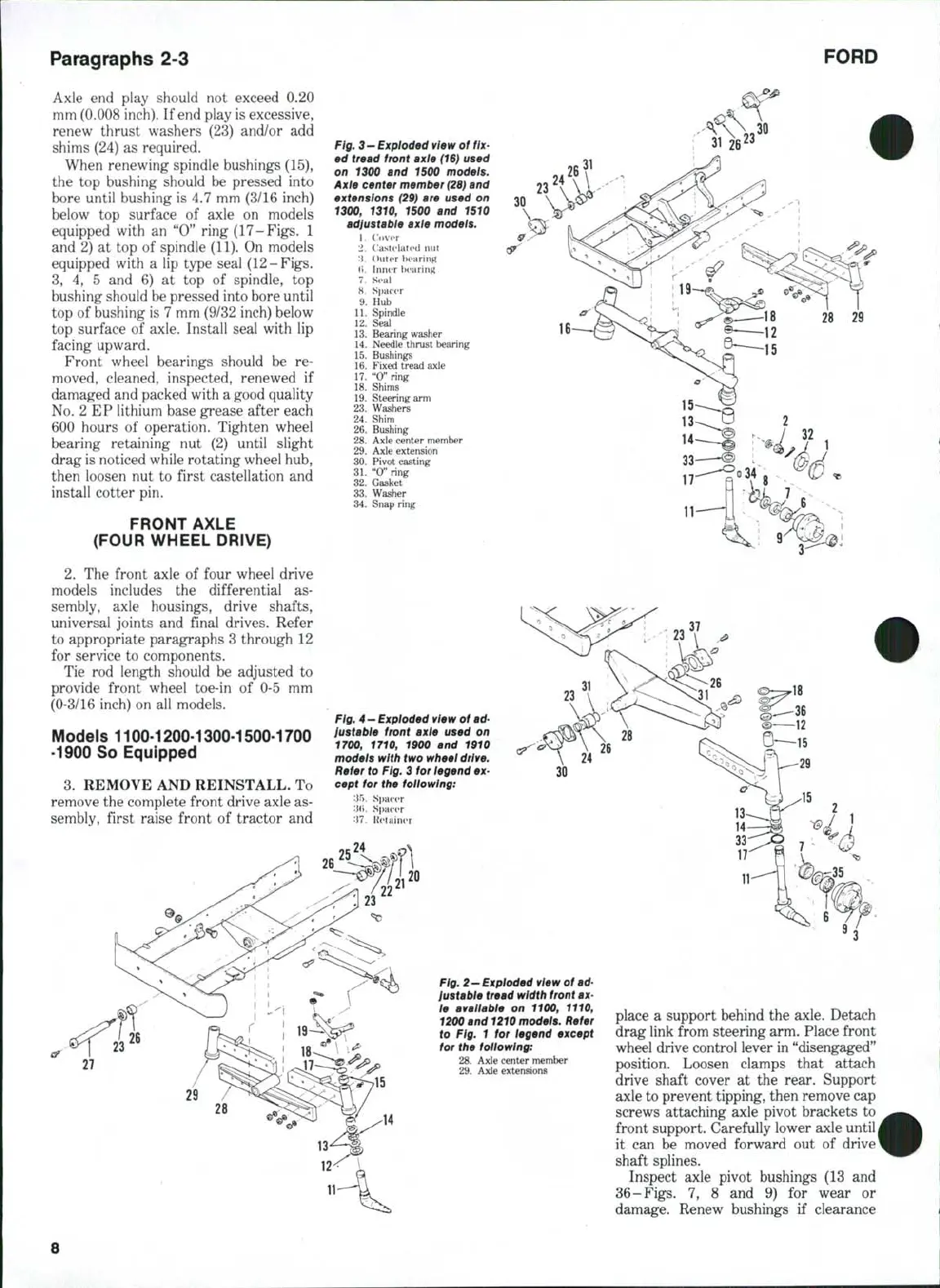

Fig.

3-Exploded view of

fix-

ed tread front axle

(16)

used

an 1300 and 1500 models.

Axle center member

(2S)

and

extensions (29} are used on

1300, 1310, 1500 and 1510

adiustable axie modeis.

1.

Cover

2.

llastelatcd

nut

:i.

Outer b(»aring

(i.

Inner iH'aring

7.

Seal

8.

Spacer

9.

Hub

11.

Spindle

12.

Seal

13.

Bearing washer

14.

Needle thrust bearing

15.

Bushings

16.

Fixed tread axle

17.

"0"

ring

18.

Shims

19.

Steering

arm

23.

Washers

24.

Shim

26.

Bushing

28.

Axle center member

29.

Axle extension

30.

Pivot casting

31.

"0"

ring

32.

Gasket

33.

Washer

34.

Snap ring

30

37

18

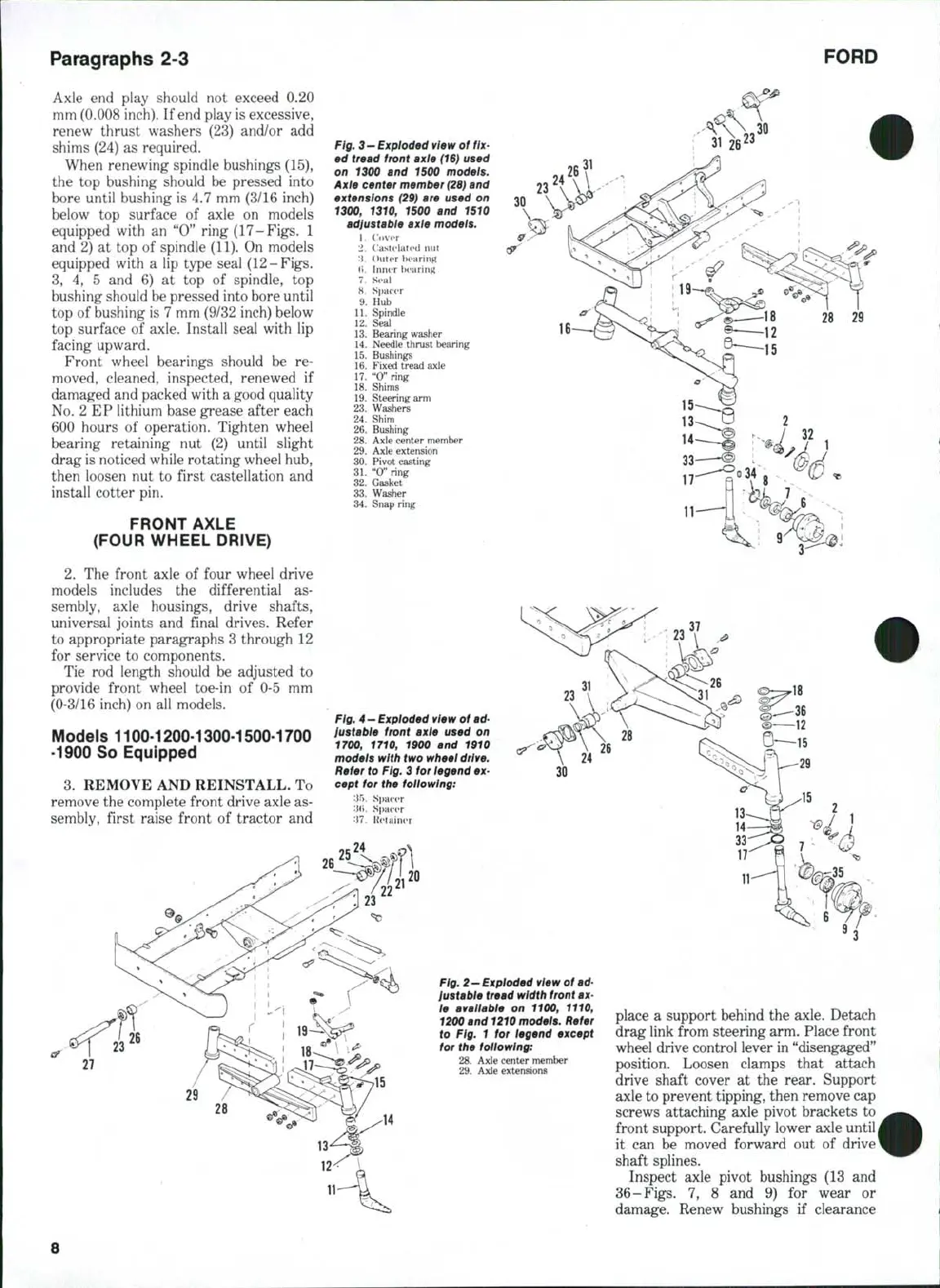

Ftg.

4 —

Expioded view of

ad-

iustabie front axle used on

1700, 1710, 1900 and 1910

models with two wheei drive.

Refer to

Fig.

3 for iegend

ex-

cept for the foiiowing:

'•\^y.

Spacer

'•\i\.

Spacer

'M. Retainer

Fig.

2-Exploded view of

ad-

iustabie tread width

front

ax-

le avaliabie on 1100, 1110,

1200

and

1210

models. Refer

to Fig. 1 for legend except

for the foltowtng:

28.

Axle center member

29.

Axle extensions

place a support behind the axle. Detach

drag link from steering arm. Place front

wheel drive control lever in "disengaged"

position. Loosen clamps that attach

drive shaft cover at the rear. Support

axle to prevent tipping, then remove cap

screws attaching axle pivot brackets to

front support. Carefully lower axle until

it can be moved forward out of drive

shaft splines.

Inspect axle pivot bushings (13 and

36-Figs. 7, 8 and 9) for wear or

damage. Renew bushings if clearance

Loading...

Loading...