24

Preparing Alumi-

num Cables for

Connection

The AC-side terminals are designed for connecting single-wire, round aluminum cables.

Due to the reaction of aluminum with air that creates a tough, non-conductive oxide layer

the following points must be considered when connecting aluminum cables:

- Reduced rated currents for aluminum cables

- The connection requirements listed below

Connection Requirements:

Carefully clean off the oxide layer of the stripped end of the cable, e.g., using a knife.

IMPORTANT! Do not use brushes, files, or sandpaper; aluminum particles may get stuck

and can transfer to other cables.

After removing the oxide layer of the cable end, rub in a neutral grease, e.g., acid-free

and alkali-free Vaseline.

Then immediately connect it to the terminal.

Monitoring the

Grid

Connecting the

inverter to the

public grid (AC)

IMPORTANT! The ground conductor GND of the AC cable must be laid so that it is discon-

nected last.

Measure the ground conductor GND longer, for example, and loop.

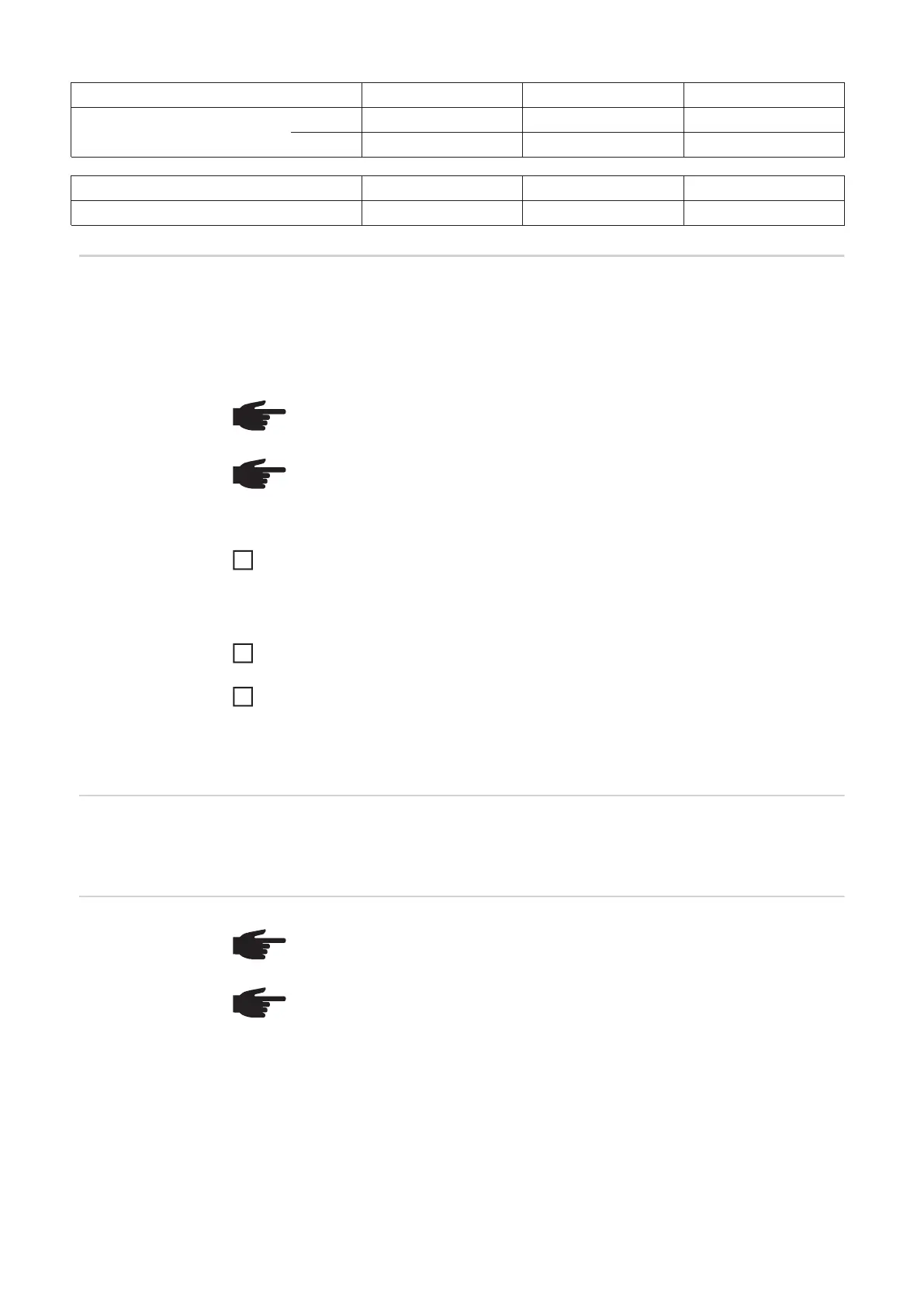

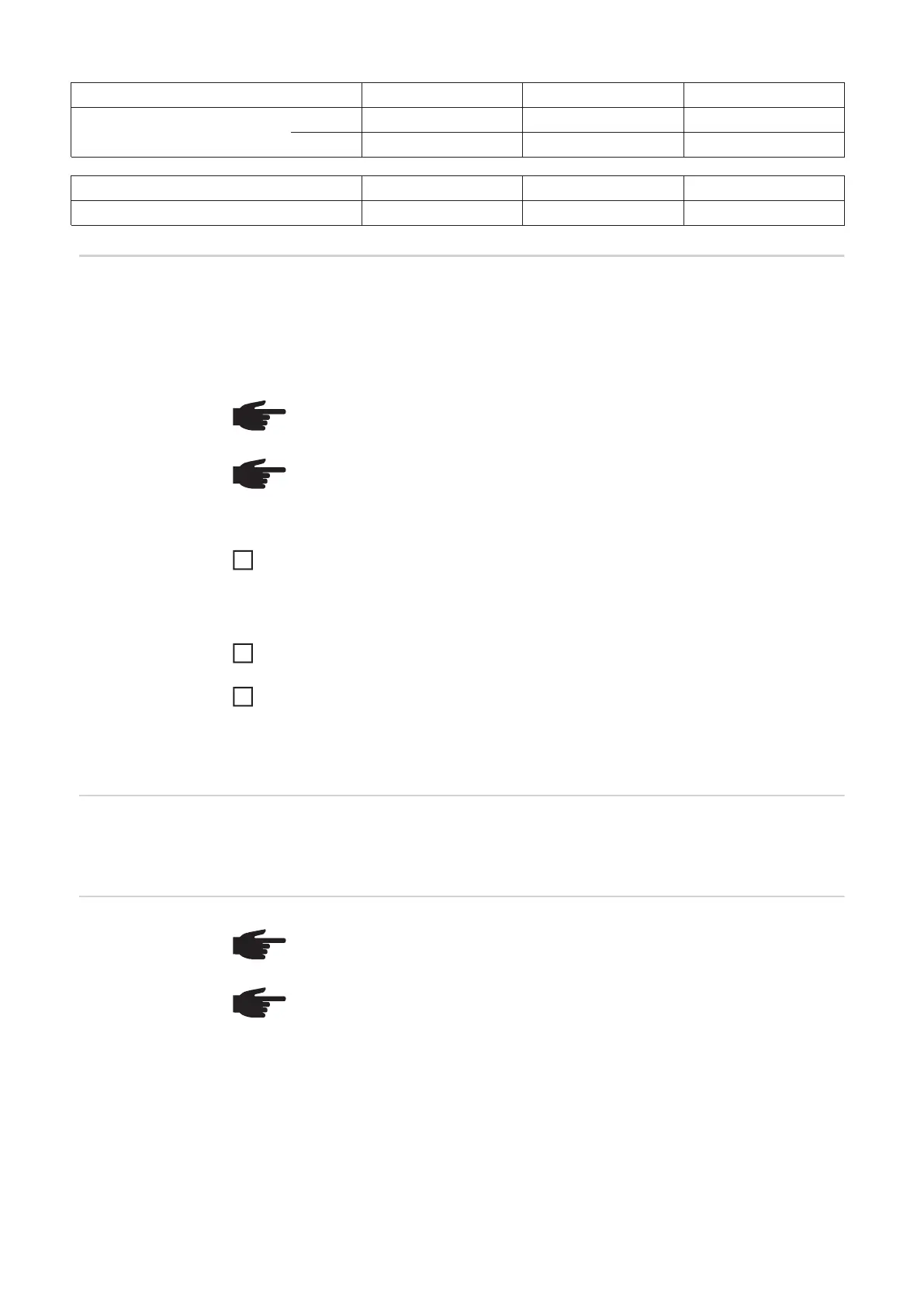

15.0-3 480 20.0-3 480 22.7-3 480

Copper (Cu)/aluminum (Al)

440 V

AC

AWG 14/AWG 12 AWG 10/AWG 10 AWG 8/AWG 8

480 V

AC

AWG 14/AWG 12 AWG 12/AWG 10 AWG 10/AWG 8

24.0-3 480

Copper (Cu)/aluminum (Al) 480 V

AC

AWG 10/AWG 10

NOTE! Always follow the instructions of the cable manufacturer when using alu-

minum cables.

NOTE! Take into account local specifications when configuring cable cross sec-

tions.

IMPORTANT! Repeat the steps above whenever the cable is disconnected and then re-

connected.

1

2

3

IMPORTANT! The resistance in the leads to the AC-side connection terminals must be as

low as possible for optimal functioning of grid monitoring.

NOTE! To ensure a proper ground connection, all grounding terminals GND must

be tightened with the specified torque during installation.

NOTE! Form loops of at least 4 in. (102 mm) in the AC cables when connecting

them to the AC terminals.

Loading...

Loading...