8-7

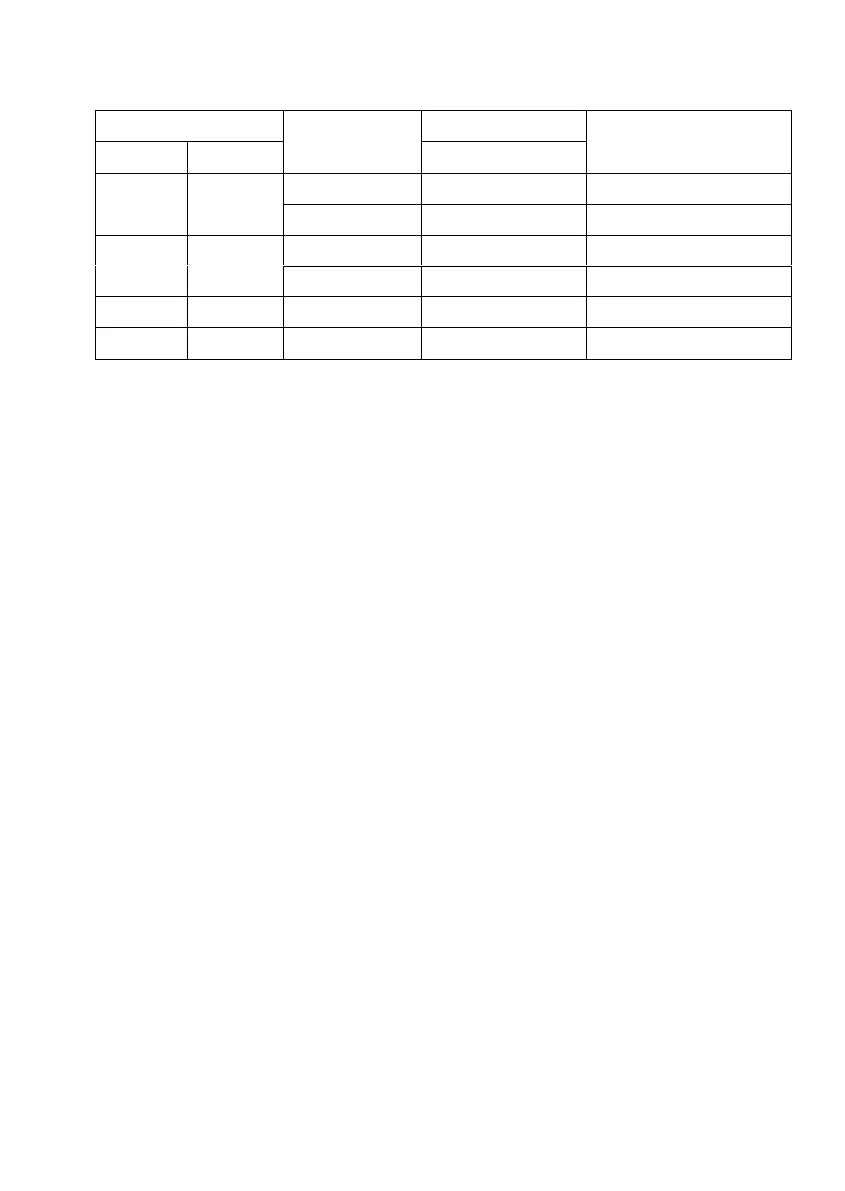

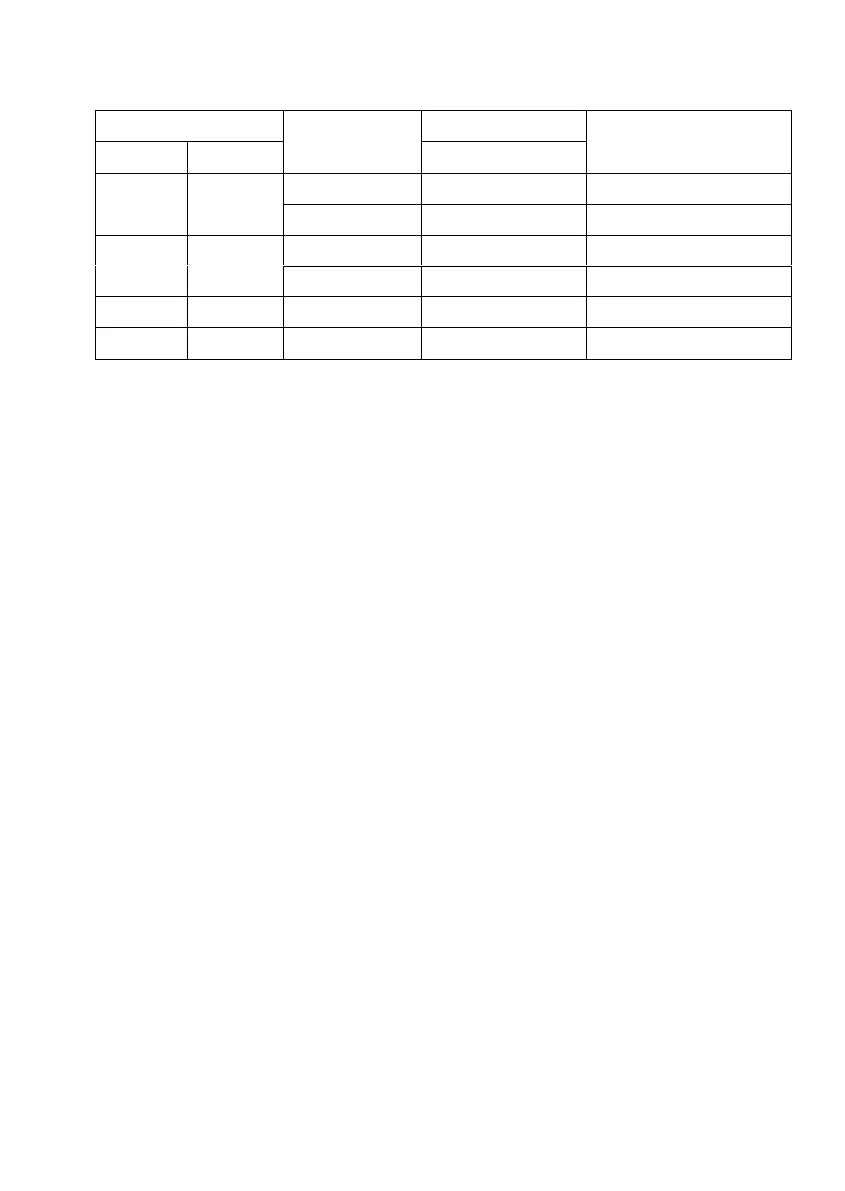

Table 8.4 Operation of STO Functional Safety Function

Digital input signals Alarm ECF Digital output signal Inverter status

[EN1] [EN2] [Y*] (DECF)

Shorted Shorted No issue ON Ready to run

Issue OFF Output shutdown (STO)

Opened Opened No issue ON Output shutdown (STO)

Issue OFF Output shutdown (STO)

Shorted Opened Issue OFF Output shutdown (STO)

Opened Shorted Issue OFF Output shutdown (STO)

8.6.2 Notes for compliance to Functional Safety Standard

1) Wiring for terminals [EN1] (Enable input 1) and [EN2] (Enable input 2)

- [EN1]/[EN2] and [PLC] are terminals prepared for connection of safety related wires; therefore, careful wiring

should be performed to ensure that no short-circuit(s) can occur to these terminals.

- For opening and closing the hardware circuit between terminals [EN1]/[EN2] and [PLC], use safety approved

components such as safety switches and safety relays that comply with EN ISO13849-1 Cat. 3 PL=e or

higher to ensure a complete shutoff.

- Input cables of [EN1] and [EN2] must be segregated in different electrical conductors installed inside

different conduits, otherwise the use of independent shielded cables is a must. The armor of the conduit or

the shield must be connected to CM terminal.

- It is the responsibility of the machinery manufacturer to guarantee that a short-circuiting or other fault does

not occur in wiring of external safety components between terminals [EN1]/[EN2] and [PLC].

Fault Examples:

• Terminals [EN1]/[EN2] and [PLC] are short-circuited due to the wiring being caught in the door of the

control panel so that a current continues to flow in terminal [EN1]/[EN2] although the safety component is

OFF and therefore the safety function will/may NOT operate

• The wiring is in contact with any other wire so that a current continues to flow in terminal [EN1]/[EN2] and

therefore the safety function will/may NOT operate

2) Notes for Safe Torque Off (STO) function

- When configuring the product safety system with this Safe Torque Off (STO) function, make a risk

assessment of not only the external equipment and wiring connected to terminals [EN1] and [EN2] (Enable

input 1 and Enable input 2) but also the whole system including other equipment, devices and wiring against

the product safety system required by the machinery manufacturer under the manufacturer's responsibility in

order to confirm that the whole system conforms to the product safety system required by the machinery

manufacturer.

In addition, as preventive maintenance, the machinery manufacturer must perform periodical inspections to

check that the product safety system properly functions.

- Inverter is designed according to Pollution Degree 2 environment. If the inverter is installed inside a worse

environment (for example, Pollution Degree 3 environment), the inverter may be damaged. Even though,

Loading...

Loading...