En-9

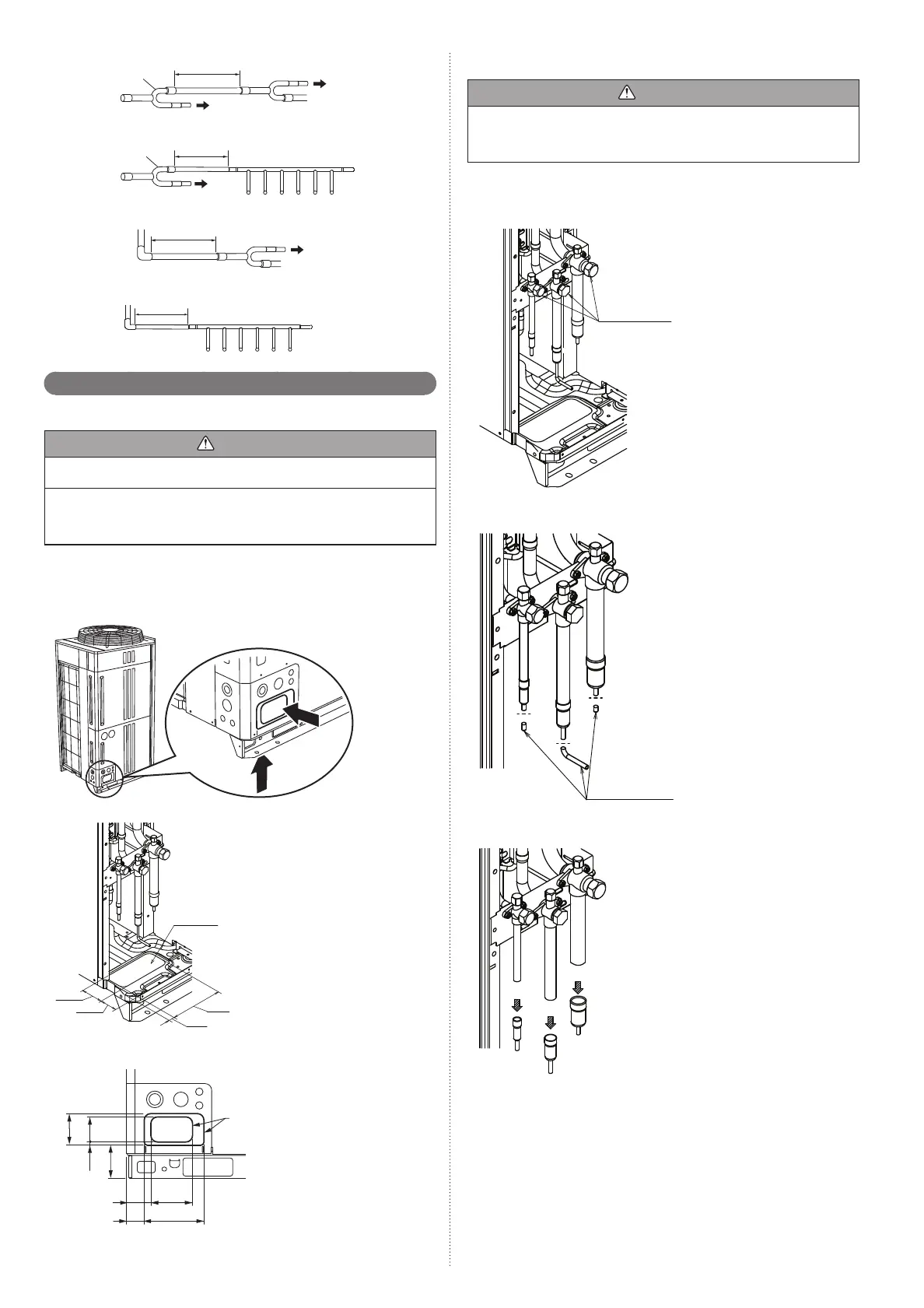

Main pipe

0.5 m or more

To indoo r u n it

To indoo r u n it

To indoo r u n it

Main pipe

0.5 m or more

To indoo r

unit

Separation tube

or

Header

0.5 m or more

0.5 m or more

To indoo r u n it

or

Header

Separation tube

To indoo r

unit

Piping method5. 3.

Opening the knockout hole5. 3. 1.

CAUTION

Be careful to prevent panel deformation or damaged while opening the knockout

hole.

To prevent cutting of the wiring after the knockout hole was opened, remove the

burrs along the edge.

In addition, to prevent rusting, painting the edge with rust preventive paint is recom-

mended.

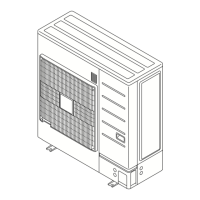

The piping can be connected from 2 directions; the front or the bottom.

(Knockout holes are provided so that the piping can be connected from 2 different

directions.)

Use the front knockout hole, as required.

A Knockout positionFig.

B Detail of knockout position (bottom)Fig.

Knockout hole

(Unit: mm)

197

42

82

80

C Detail of knockout position (front)Fig.

75

95

10

100

43

73

199

125

Knockout

hole

(Unit: mm)

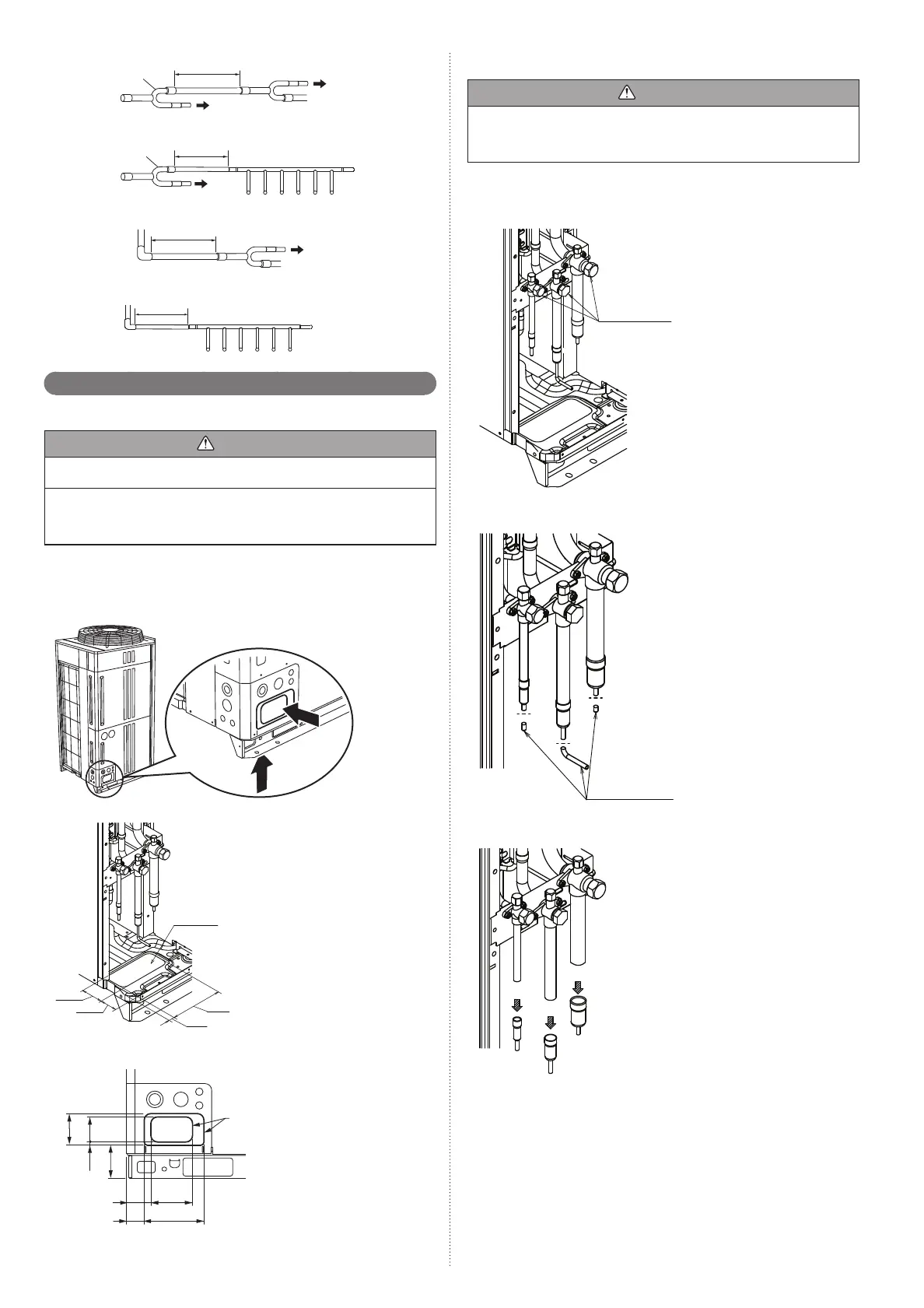

Removing the pinch pipe5. 3. 2.

WARNING

Remove the pinch pipe only when the internal gas is completely drained as shown

on the below instructions.

If gas still remains inside, the piping may crack if you melt the brazing fi ller metal of

the junction area with a burner.

Before connecting the piping, remove the pinch pipe in accordance with the following

instructions:

Verify that the liquid side , suction gas side and discharge gas side 3-way valves 1)

are closed.

3-way valves

Cut the end of the liquid side , suction gas side and discharge gas side pinch pipe 2)

and vent the gas inside the pinch pipe.

End of pinch pipe

After all the gas is vented, melt the brazing fi ller metal on connecting part using a 3)

torch and remove the pinch pipe.

9378945111_IM.indb Sec1:99378945111_IM.indb Sec1:9 2012/11/14 09:48:592012/11/14 09:48:59

Loading...

Loading...