24

880397M_MSW_GFX4-GFXTERMO4_08-2018_ENG

ALARMS

GENERIC ALARMS AL1, AL2, AL3 and AL4

Four generic alarms are always available and can perform various functions.

Typically, alarm AL.1 is defined as minimum and AL.2 as maximum.

These alarms are set as follows:

- select the reference variable to be used to monitor the value (parameters A1.r, A2.r, A3.r and A4.r): the origin of the

variable can be chosen from the process variable PV (generally linked to the main input), the ammeter input, the voltmeter

input, the auxiliary analog input, or the active setpoint.

- set the value of the alarm setpoint (parameters AL.1, AL.2, AL.3 and AL.4).

This value is used for comparison with the reference variable value: it can be absolute or indicate a shift from the variable in

case of deviation alarm.

- set the hysteresis value for the alarm (parameters Hy.1, Hy.2, Hy.3 and Hy.4):

the hysteresis value defines a band for safe re-entry of the alarm condition: without this band, the alarm would be deactivated

as soon as the reference variable re-entered the setpoint limits, with the possibility of generating another alarm signal in the

presence of oscillations of the reference signal around the setpoint value.

- select alarm type:

- absolute/deviation: if the alarm refers to an absolute value or to another variable (for example, to the setpoint).

- direct/reverse: if the reference variable exceeds the alarm setpoint in the “same direction” as the control action or not. For

example, the alarm is direct if the reference variable exceed the upper setpoint value during heating or assumes values below

the lower setpoint during cooling. In the same manner, the alarm is reverse if the reference variable assumes values below

the lower setpoint during heating or exceeds the setpoint during cooling.

- normal/symmetrical: if band value is subtracted or added, respectively, to/from the upper and lower limit of the alarm setpoints

or indicates a higher and lower band compared to the alarm setpoint.

- with/without disabling at switch-on: if you want to check the reference variable value at system switch-on or wait until the

variable enters the control window.

- with/without memory: if the alarm signal persists even when the cause has been eliminated or stops when the variable returns

to normal values.

- definition of upper and lower limits for setting absolute alarms: if the alarm is used to check that the operator does

not set a setpoint value outside a certain band during multiset operation. The above concepts are better explained in the fol-

lowing figures:

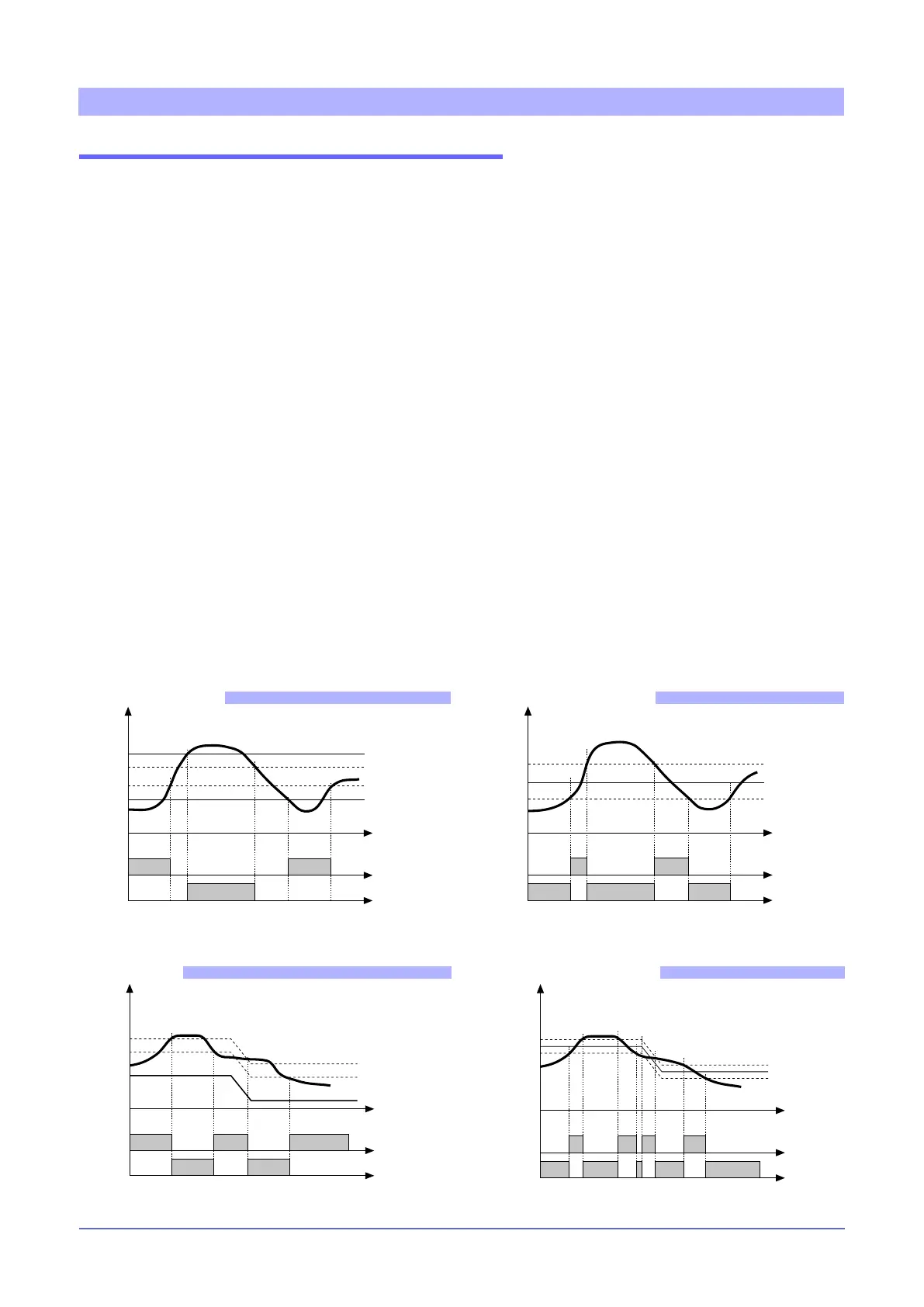

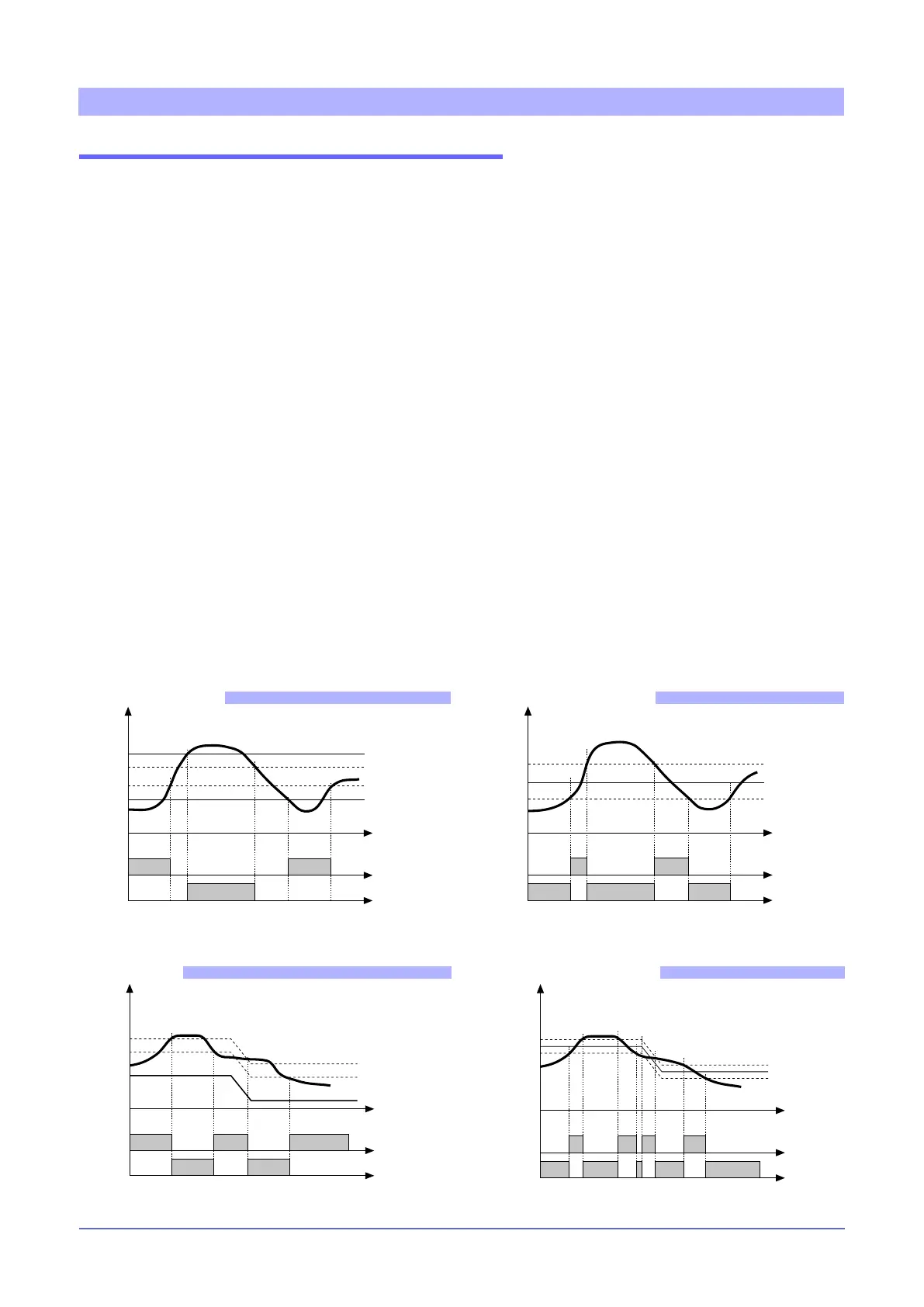

time

AL1 + Hyst1

AL2 + Hyst2

AL2

AL1

allarm 1

allarm 2

(*)

For AL1 reverse absolute alarm (low) with positive Hyst1, AL1 t = 1 (*) = OFF

if disabled at switch on

For AL2 direct absolute alarm (high) with negative Hyst2, AL2 t = 0

Normal absolute alarm

For AL1 = symmetrical inverse absolute alarm with Hyst1, AL1 t = 5

For AL1 = symmetrical direct absolute alarm with Hyst1, AL1 t = 4

Minimum hysteresis = 2 scale points

Inverse

Direct

AL1

AL1 + [ Hyst1 ]

AL1 - [ Hyst1 ]

time

Symmetrical absolute alarm

For AL1 = normal inverse deviation alarm with negative Hyst 1, AL1 t = 3

For AL1 = normal direct deviation alarm with negative Hyst 1, AL1 t = 2

SP+AL1

SP

Inverse

Direct

time

Hyst1

Deviation alarm

For AL1 = Symmetrical inverse deviation alarm with Hyst 1, AL1 t = 7

For AL1 = Symmetrical direct deviation alarm with Hyst 1, AL1 t = 6

time

SP+AL1

SP

Inverse

Direct

SP-AL1

Symmetrical deviation alarm

Loading...

Loading...