44

880397M_MSW_GFX4-GFXTERMO4_08-2018_ENG

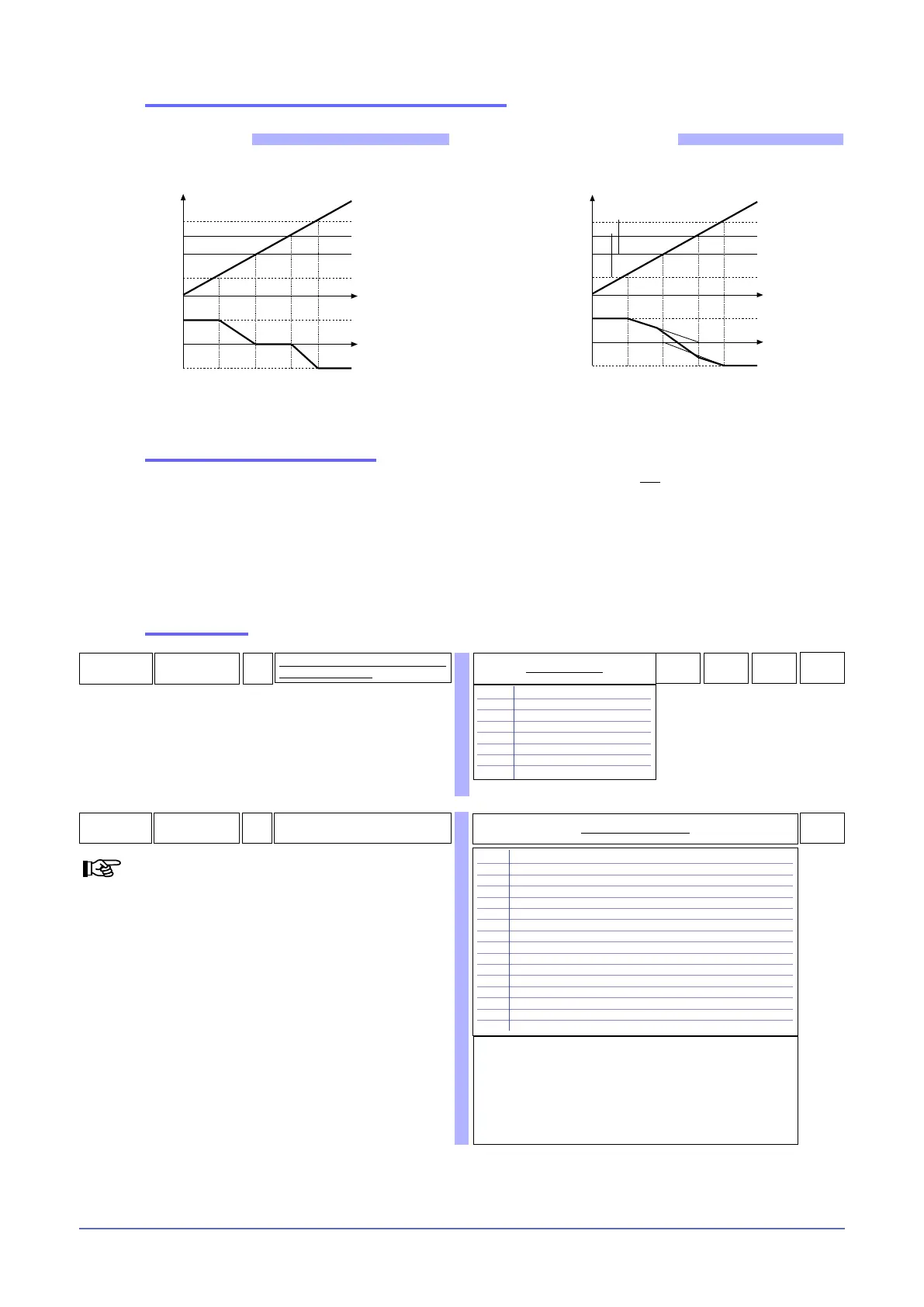

Control output with only proportional action in case of proportional

heating band separate from cooling band.

Control output with only proportional action in case of proportional

heating band superimposed on cooling band.

Output with separate band Output with superimposed band

Heat/cool control with separate or superimposed band

Heat/cool control with relative gain

This control mode (enabled with parameter Ctr = 14) asks you to specify cooling type. The PID cooling parameters are then cal-

culated based on heating parameters in the ratio specified (ex: C.ME = 1 (oil), H_Pb = 10, H_dt =1, H_It = 4 implies: C_Pb = 12.5, C_dt = 1

, C_It = 4)

Apply the following values when setting cycle times:

Air T Cool cycle = 10 sec.

Oil T Cool cycle = 4 sec.

Water T Cool cycle = 2 sec.

NB.: Cool parameters cannot be changed in this mode.

180

(tr

R/W

Control type

134

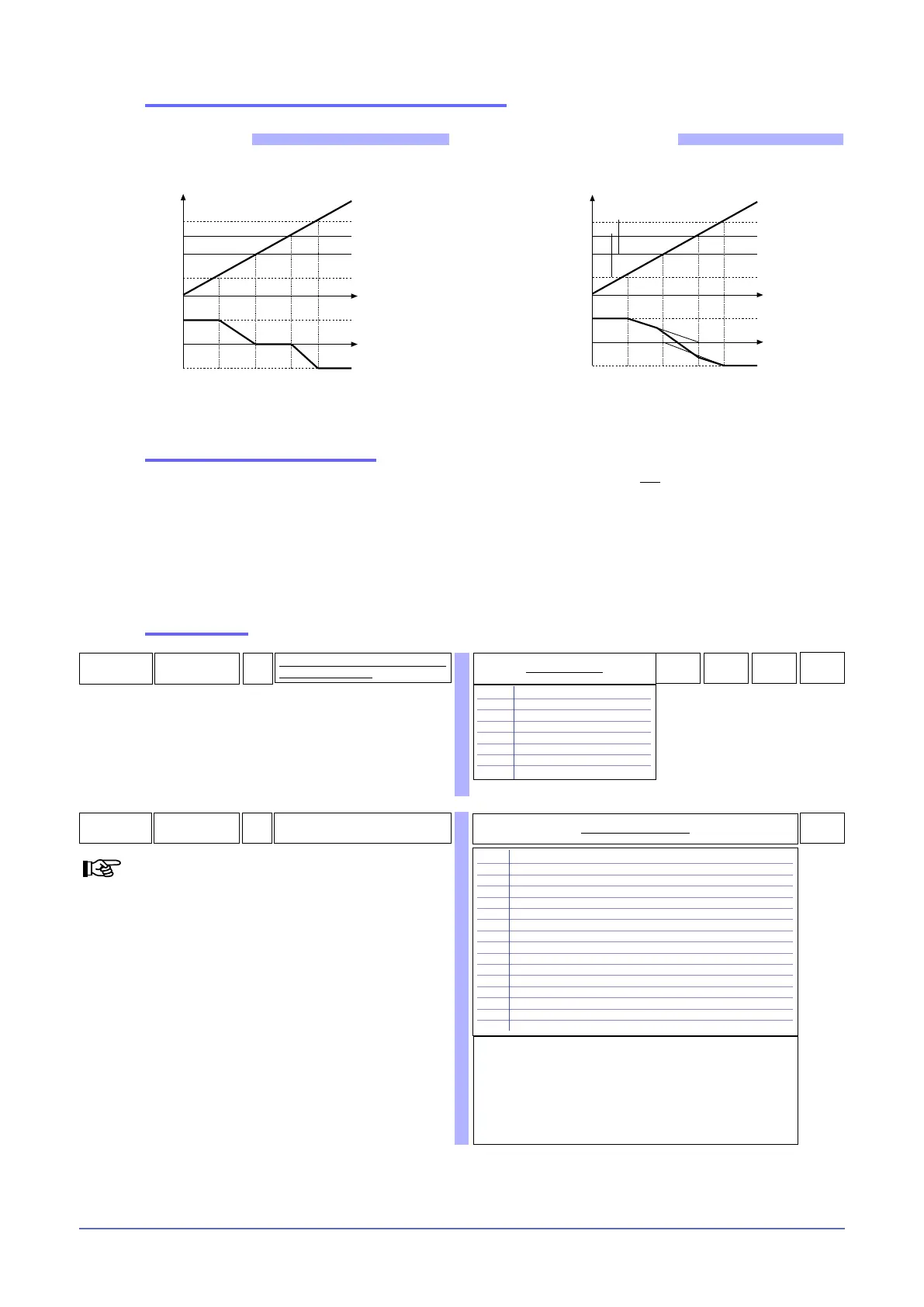

Table of heat/cool controls

Select sample time for derivative action.

+0 sample 1 sec.

+16 sample 4 sec.

+32 sample 8 sec.

+64 sample 240 msec.

+128 No Reset of integral component at setpoint change

Note: the LBA alarm is not enabled in the ON/OFF control.

Val Control type

0 P heat

1 P cool

2 P heat / cool

3 PI heat

4 PI cool

5 PI heat / cool

6 PID heat

7 PID cool

8 PID heat / cool

9 ON-OFF heat

10 ON-OFF cool

11 ON-OFF heat / cool

12 PID heat + ON-OFF cool

13 ON-OFF heat + PID cool

14 PID heat + cool with relative gain (see parameter C.ME)

PID Parameters

PV = process variable

SP + cSP = cooling setpoint

c_Pb = cooling proportional band

Time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

Time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

PV = process variable

SP = heating setpoint

h_Pb = heating proportional band

WARNING: the Control ( “Ctr”) default parameter changed

from “6” to “134” starting from products with serial

number “SN 1013A1965” ( March 2010).

The option “+128”, used to disable the “Integral power reset” has

been introduced as an improvement, starting from the Software

version “1.43”.

We strongly suggest to verify the eventual recipes created with

Software versions before the 1.43, because, if the parameter

“Ctr” is included in the recipe, it could be congured in an unde-

sirable way.

617

spu

R/W

Selection of process variable of zone /

Zone reference power

1 PV zone 1

2 PV zone 2

3 PV zone 3

4 PV zone 4

9 POWER zone 1 (*)

10 POWER zone 2 (*)

11 POWER zone 3 (*)

12 POWER zone 4 (*)

Table of selections

(*):

- The reference power of a slave zone in automatic mode is the power of a master

zone in automatic or manual mode.

- The reference power of a slave zone in manual mode is the zone manual power.

- Software shutdown remains independent for each zone.

1

zone 1

2

zone 2

3

zone 3

4

zone 4

Loading...

Loading...