&200,66,21,1*

&219(56,216(7

This operation should be carried out by a qualified

professional equipped with a calibrated combustion

analyser.

Before each intervention, switch off electrical and

gas supplies.

The boiler is pre-set in work for Natural gas H (G20)

or for LPG (G31).

&RQYHUVLRQIURP1DWXUDOJDV+WR/3*

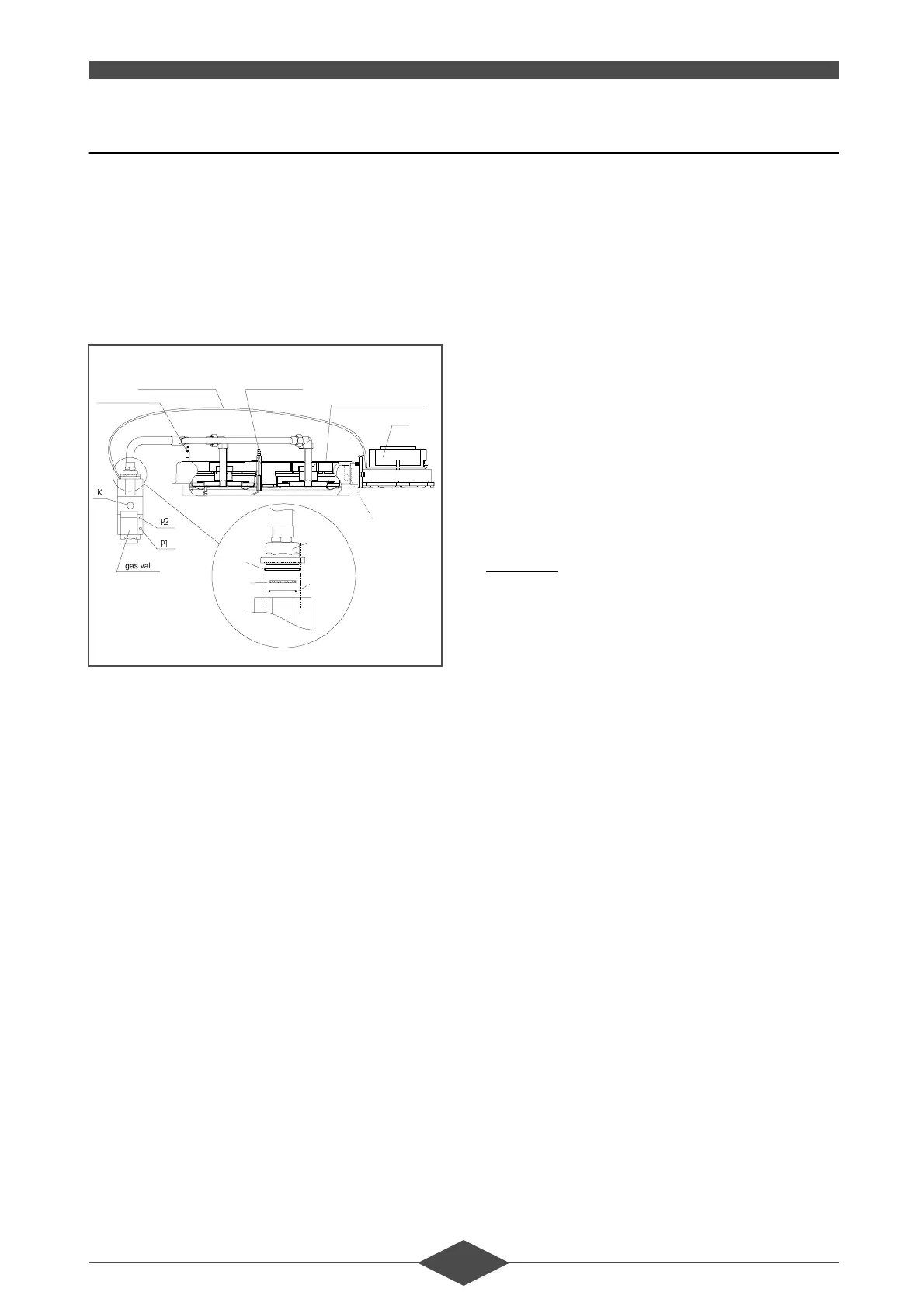

- Replace gas reducer Ø 7.30 (Natural gas H) by

gas reducer Ø 5.60 at the gas valve outlet

(fig. 23).

- Insert air ring Ø 31 into the burner sleeve (fig. 23).

- Check combustion parameters (see table § 3 - V

- COMMISSIONING).

- If necessary, proceed to the adjustment of gas

valve according the process described hereafter

(a CO

2

/CO analyser calibrated beforehand is

necessary).

&RQYHUVLRQIURP/3*WR1DWXUDOJDV+

- Replace gas reducer Ø 5.60 by gas reducer

Ø 7.30 (Natural gas H) at the gas valve outlet

(fig. 23).

- Remove air ring Ø 31 from the burner sleeve

(fig. 23).

- Check combustion parameters (see table § 3 - V

- COMMISSIONING).

- If necessary, proceed to the adjustment of gas

valve according the process described hereafter

(a CO

2

/CO analyser calibrated beforehand is

necessary).

$GMXVWPHQWSURFHVV

- Commission the burner by pushing for about

5 seconds on button A of the control board -

Switch to flashing "7" on the display. Check the

gas tightness with a foaming product (inlet con-

nections of the boiler, inlet/outlet of the gas valve,

outlet of the gas tube).

- Gradually set the sanitary potentiometer to the

right hand stop point (burner at maximum rate).

- Check the CO

2

/CO rate according to the table § 3

- V - COMMISSIONING. The flow rate at the max-

imum setting is not adjustable, it’s given by the

gas reducer.

- Set the sanitary potentiometer to the left hand

stop point (burner at minimum rate).

- Check the CO

2

/CO rate according to the table § 3

- V - COMMISSIONING and adjust the V screw if

necessary (screwing increases the gas flow, un-

screwing reduces it).

Reminder:

- Before adjusting the minimum rate (screw K),

wait for a stable CO

2

/CO reading on the analyser.

Switch from minimum to maximum rate several

times to ensure that the adjustment has been

made correctly. Use an accurately calibrated

analyser.

.

3

3

gas valve

Ignition electrode

Air/Gas servo system

Ionisation probe

Burner THR 10-50 GN/GP

Fan

Brass air ring

31

only for

propane gas

∅

Gas valve

Flange

O-ring

Gas reducer

O-ring

Gas valve

flange

Gas

reducer

)LJ

Loading...

Loading...