PART 2

Page 24

AC GENERATORS

SECTION 2.2

BRUSHED EXCITATION TROUBLESHOOTING FLOWCHARTS

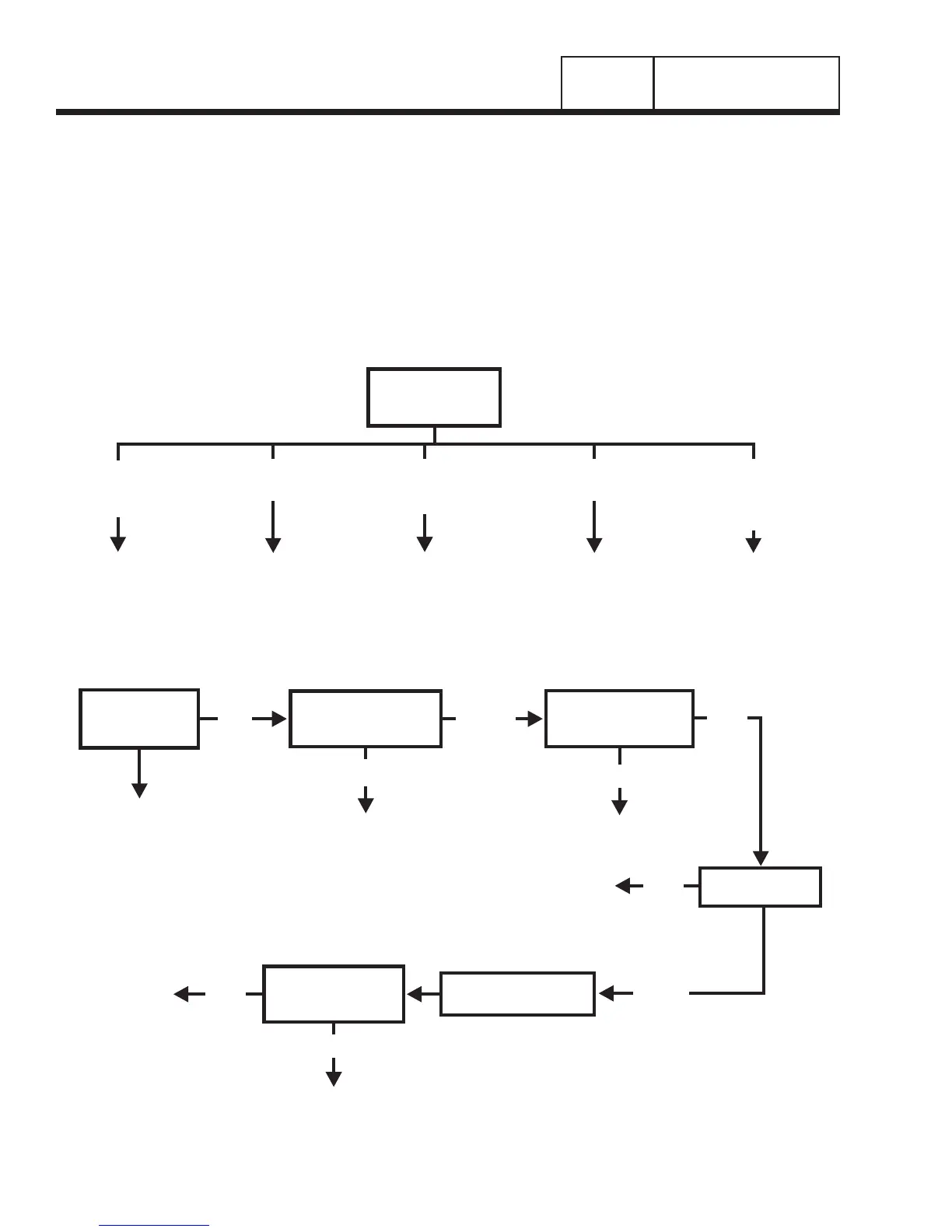

GO TO PROBLEM 6 GO TO PROBLEM 5GO TO PROBLEM 5 GO TO PROBLEM 7

VOLTAGE &

FREQUENCY BOTH

HIGH OR LOW

FREQUENCY GOOD

VOLTAGE HIGH

ZERO VOLTAGE

ZERO FREQUENCY

FREQUENCY GOOD,

LOW OR RESIDUAL

VOLTAGE

TEST 1 - CHECK

NO LOAD VOLTAGE

& FREQUENCY

NO LOAD VOLTAGE &

FREQUENCY GOOD -

VOLTAGE/FREQUENCY

FALLS OFF UNDER LOAD

If Problem Involves AC Output

VERIFY ROTOR IS SPINNING,

GO TO PROBLEM 5

REPLACE

BRUSHES

STOP TESTING

BAD

BAD

BAD

GOOD

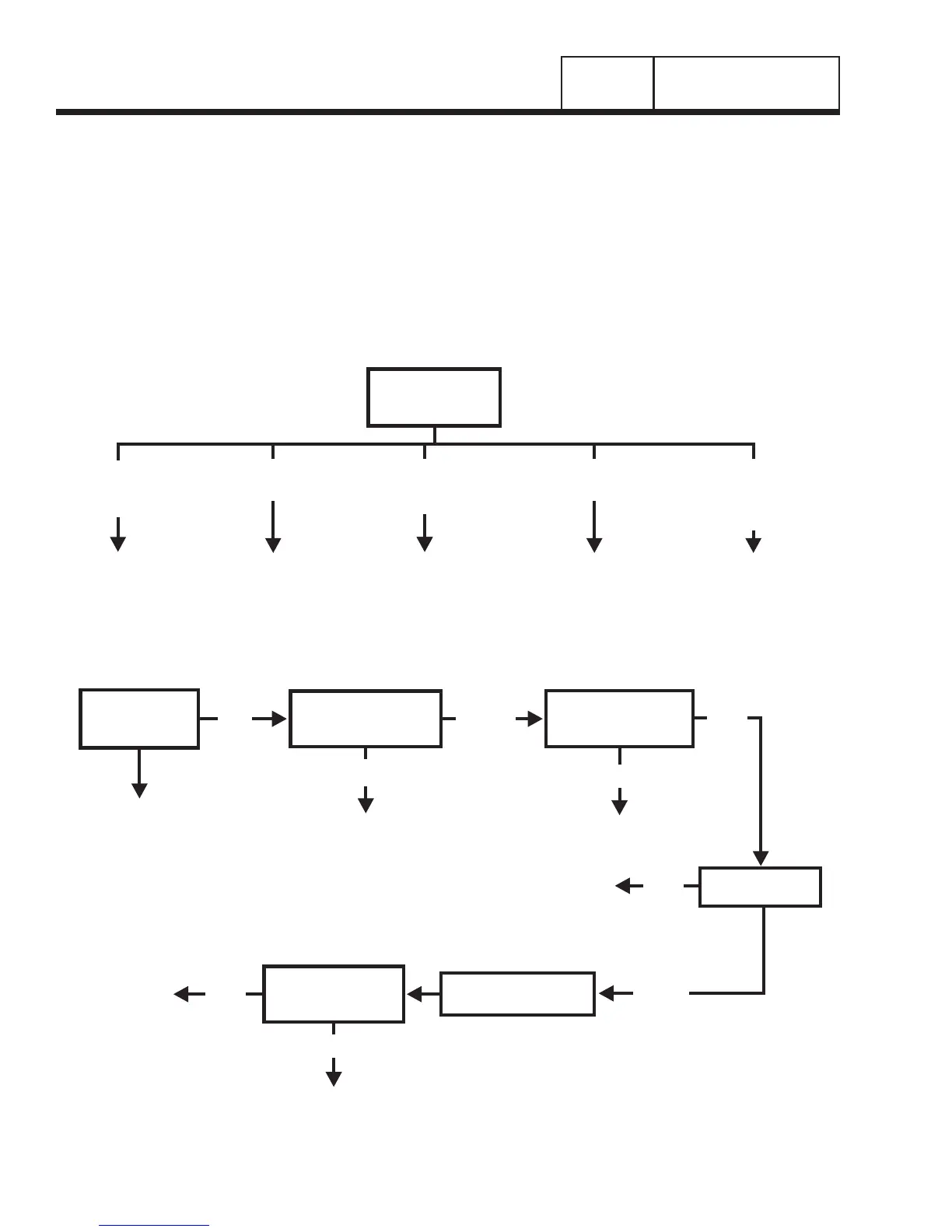

Problem 5 – Generator Produces Zero Voltage or Residual Voltage

TEST 2 – CHECK

MAIN CIRCUIT

BREAKER

RESET TO “ON”

OR REPLACE IF BAD

REPLACE COMPONENT

AS NEEDED

TEST 3 – CHECK

CONTINUITY OF

RECEPTACLE PANEL

TEST 5 – CHECK

BRUSHES

REPLACE

ALTERNATOR

REPLACE AUTOMATIC

VOLTAGE REGULATOR

TEST 12 – ADJUST

AUTOMATIC VOLTAGE

REGULATOR

ON

GOOD

GOOD

STOP TESTING

GOOD

BAD

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

The GP series portable generators currently use

three different types of alternators. Two of the alterna-

tors are brushless capacitor type with different style of

capacitors (Configuration “A” and “B”). The third uti-

lizes a voltage regulator and a brushed excitation sys-

tem (Configuration “C”). To help with troubleshooting,

two sets of flow charts have been created for these

different styles of alternators.

Identify the configuration of the alternator being ser-

viced using Sections 1.3 and 1.4 of this manual and

proceed to the appropriate flowchart section.

Configuration “A” – Brushless Capacitor, use Section 2.1

Configuration “B” – Brushless Capacitor, use Section 2.1

Configuration “C” – Brushed Excitation, use Section 2.2

Loading...

Loading...