SECTION 3.3

DIAGNOSTIC TESTS

Page 49

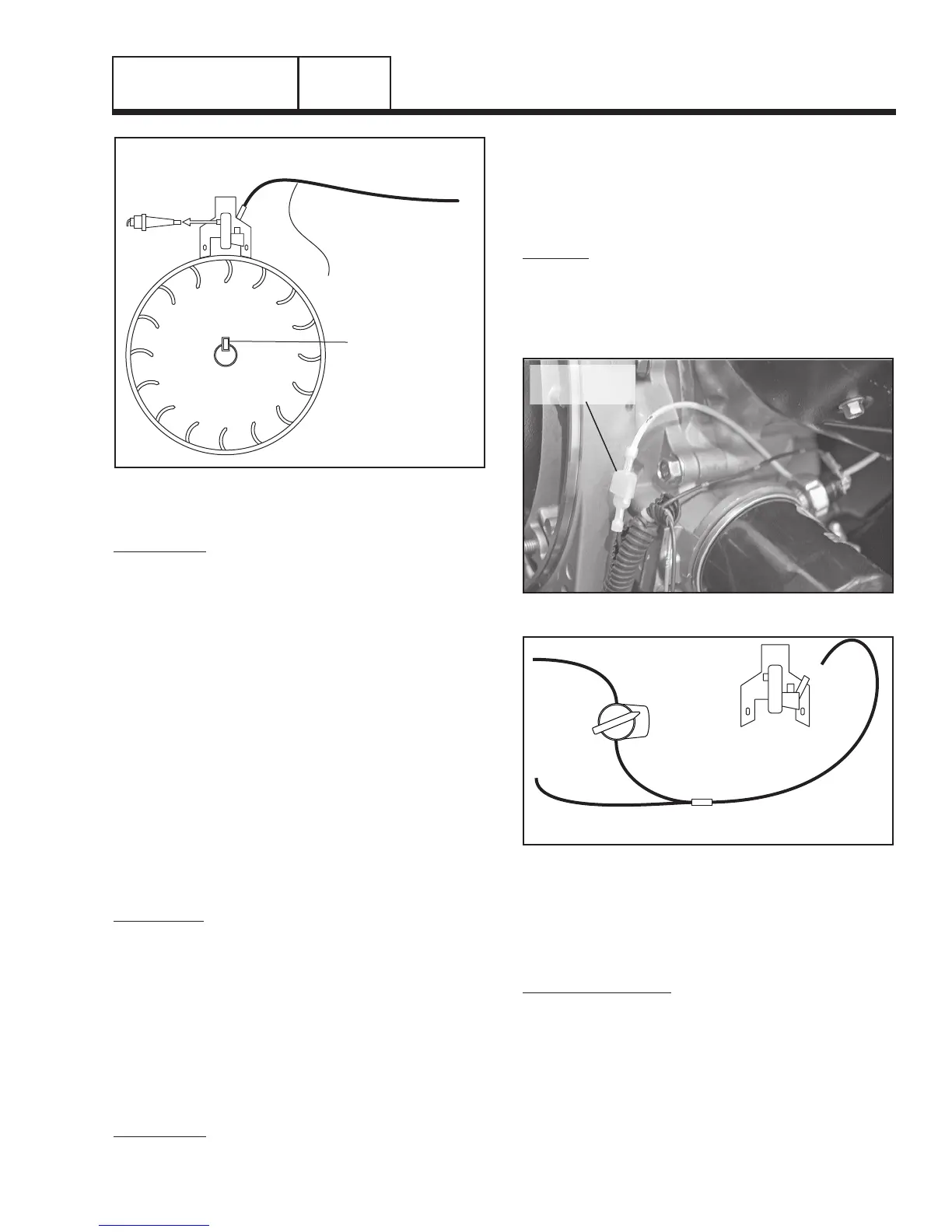

SPARK PLUG

ENGINE WIRE HARNESS

REMOVE LEAD

FLYWHEEL KEY

WIRE 18 TO

START-RUN-STOP SWITCH

(SHUTDOWN LEAD)

Figure 16. Engine Ground Harness

PROCEDURE:

1. Check the flywheel magnet by holding a screwdriver at

the extreme end of its handle and with its point down.

When the tip of the screwdriver is moved to within 3/4

inch (19mm) of the magnet, the blade should be pulled

in against the magnet.

2. For rough running or hard starting engines check the fly-

wheel key. The flywheel’s taper is locked on the crankshaft

taper by the torque of the flywheel nut. A keyway is pro-

vided for alignment only and theoretically carries no load

Note: If the flywheel key becomes sheared or even

partially sheared, ignition timing can change.

Incorrect timing can result in hard starting or fail-

ure to start.

TEST 39 – REMOVE WIRE 18 / SHUTDOWN

LEAD

DISCUSSION:

Wire 18 on all engines is used to shutdown the unit

when either the switch is placed in the OFF posi-

tion or a low oil condition has occurred. A ground

is applied to the magneto in both instances which

will inhibit spark and shutdown the unit. If a short to

ground exists on this wire the engine will be inhibited

from producing spark. This test will check the integrity

of the wire.

Note: The shutdown lead on units with the 389cc

engine will not be identified as Wire 18. Refer to

Figure 18 for identification of location.

PROCEDURE:

1. Turn off the fuel supply

2. Remove the flywheel cover so that the magneto is

exposed.

3. Disconnect Wire 18 from the magneto.

4. Repeat Test 25, “Check Ignition Spark.”

RESULTS:

1. If spark now occurs, Wire 18 has a short to ground.

Trace Wire 18 back to the START-RUN-STOP switch

and Oil Pressure Module (If so equipped).

2. If spark still does not occur, refer back to flow chart.

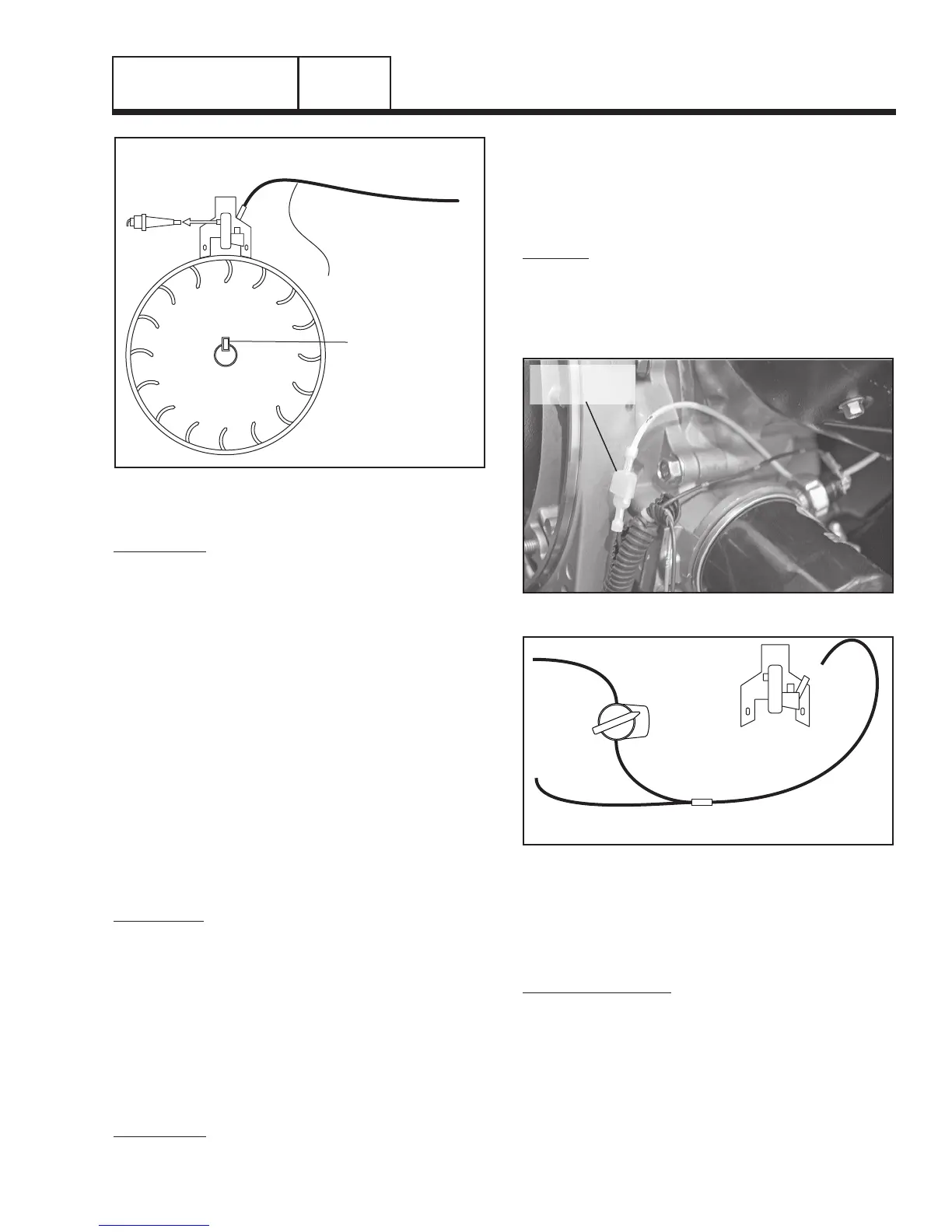

Figure 17. Wire 18 (410cc Engine)

OFF

ON

OFF-ON SWITCH

MAGNETO

SHUTDOWN HARNESS

WIRE 18

Figure 18. Shutdown Lead (389cc Engine)

TEST 40 – CHECK / ADJUST GOVERNOR

(389/206/163cc ENGINES)

INITIAL ADJUSTMENT:

1. Loosen the governor lever clamp bolt (See Figure

19).

2. While holding the governor lever in its full “INC. RPM”

position, rotate the governor shaft counter clockwise as

far as it will go.

Note: The governor shaft will only turn approx-

imately 20 degrees from a full clockwise posi-

tion. Do not apply excessive torque to the

governor shaft.

DC CONTROL

PART 3

Loading...

Loading...