SECTION 3.3

DIAGNOSTIC TESTS

Page 51

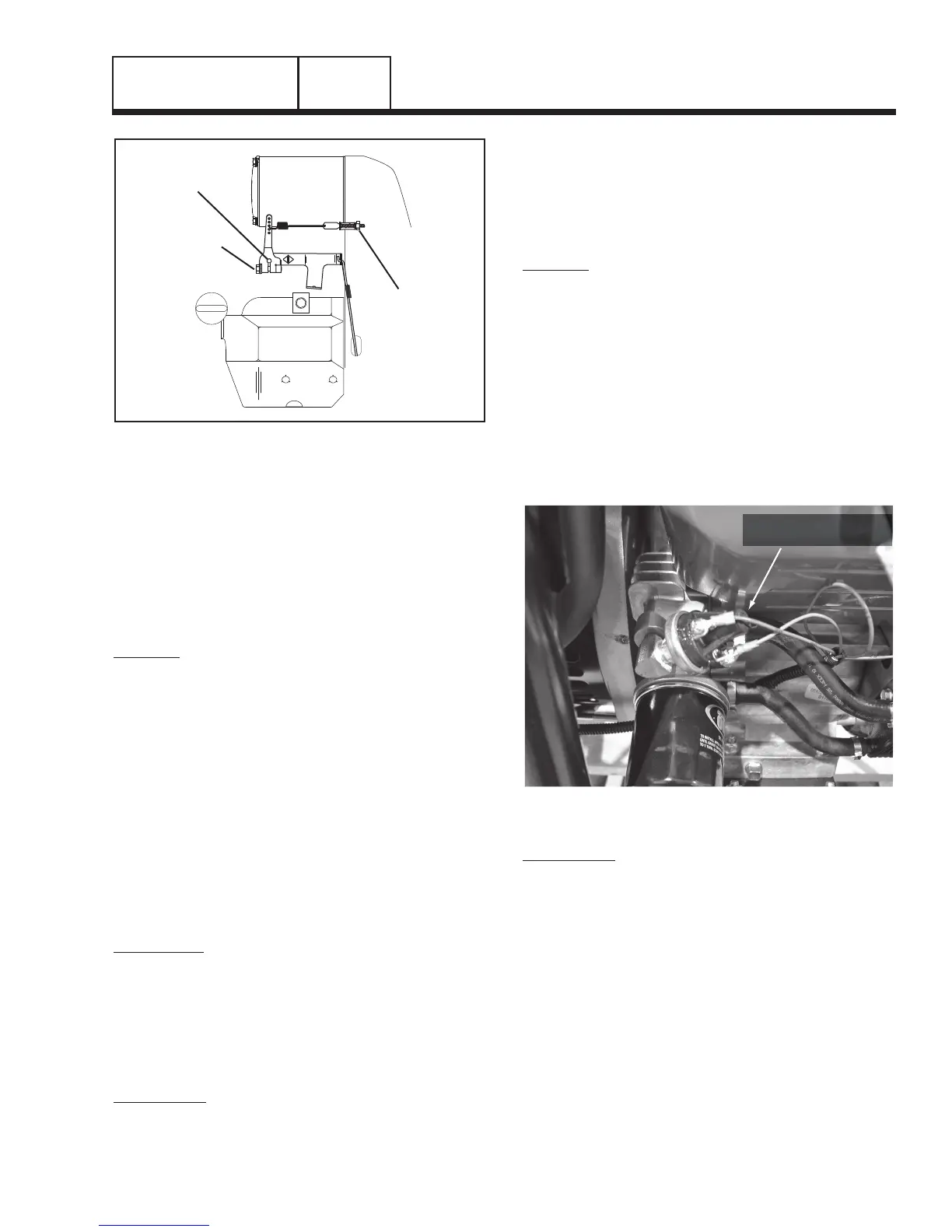

GOVERNOR

SHAFT

PRIMARY

ADJUST

SCREW

GOVERNOR

CLAMP

BOLT

Figure 20. Engine Governor Adjustment (410cc Engine)

4. Connect a frequency meter across the generators AC

output leads.

5. Turn the primary adjust screw to obtain a frequency

reading of 62.5 Hz.

6. When frequency is correct at no load, check the AC volt-

age reading. If voltage is incorrect, the voltage regulator

may require adjustment if so equipped.

RESULTS:

1. If, after adjusting the engine governor, frequency and

voltage are good, tests may be discontinued.

2. If frequency is now good, but voltage is high or low, refer

back to flow chart.

3. If engine was overspeeding, check linkage and throttle

for binding. If no governor response is indicated refer to

engine service manual.

4. If engine appears to run rough and results in low fre-

quency, proceed to Problem 26 Flow Chart.

TEST 45 – CHECK OIL LEVEL SWITCH

DISCUSSION:

The 389cc engine does not utilize oil pressure to

lubricate the internal components. It utilizes a splash

type lubrication system. The switch should be nor-

mally open as long as the engine is filled with oil. The

switch will close when the oil level drops to low the

switch will close and ground out the magnetos inhibit-

ing spark until the oil level is raised.

PROCEDURE:

1. Verify that the oil level is full.

2. Refer to Figure 3 in Section 3.3. Unplug the wire from

the oil level switch.

3. Set VOM to measure resistance.

4. Connect one meter test lead to the previously discon-

nect wire coming from the oil level switch. Connect the

other meter test lead to frame ground. INFINITY should

be measured.

RESULTS:

1. A reading of CONTINUITY indicates that the switch is no

longer functioning and will need to be replaced.

TEST 46 – CHECK OIL PRESSURE SWITCH

If the engine cranks and starts, then shuts down

almost immediately, the cause may be one or more of

the following:

• Lowengineoillevel.

• Lowoilpressure.

• Adefectiveoilpressureswitch.

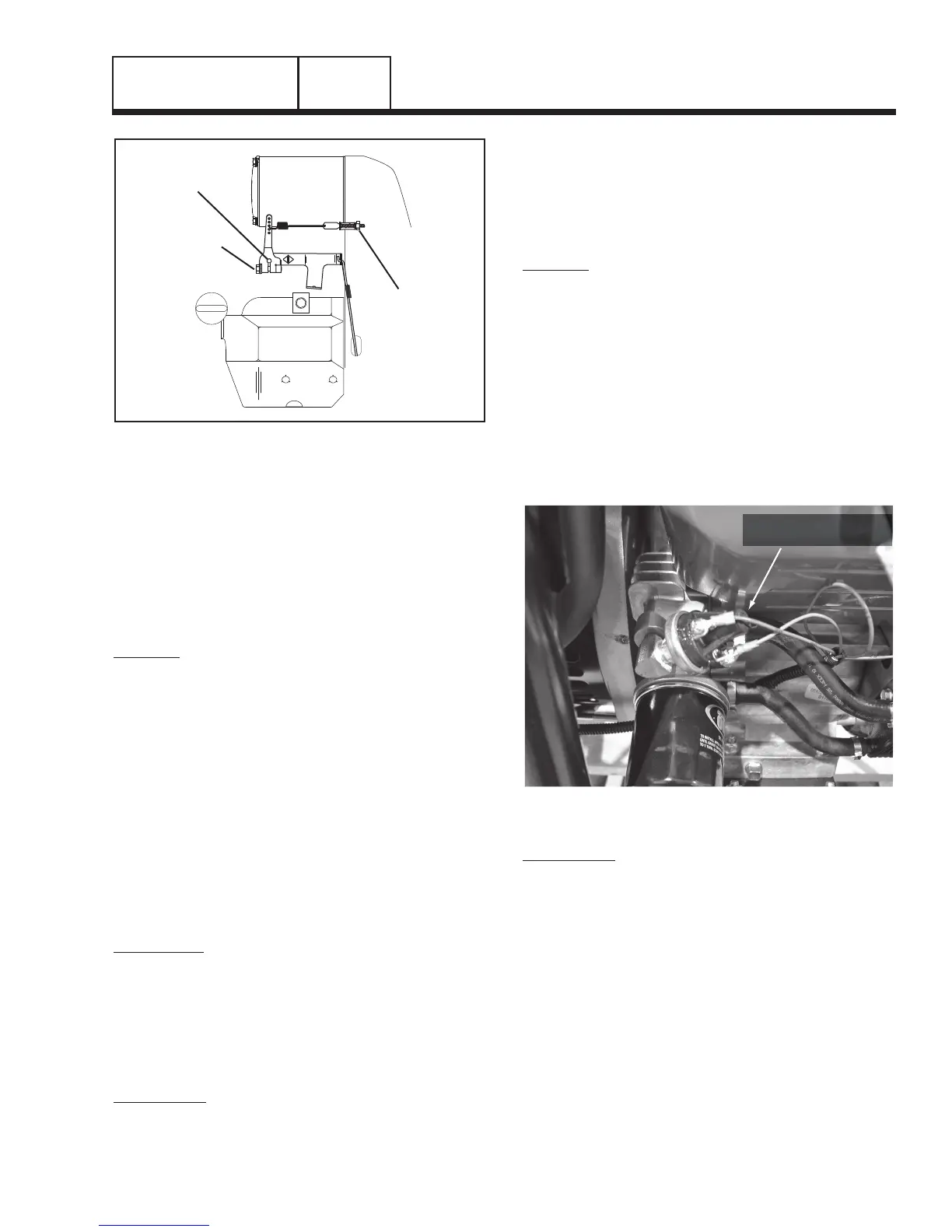

Figure 21. Low Oil Pressure Switch

PROCEDURE:

1. Check engine crankcase oil level.

a. Check engine oil level.

b. If necessary, add the recommended oil to

the dipstick FULL mark. DO NOT OVERFILL

ABOVE THE FULL MARK.

2. Do the following:

a. Disconnect Wire 86 and Wire 0 from the oil

pressure switch terminals. Remove the switch

and install an oil pressure gauge in its place.

b. Start the engine while observing the oil pres-

sure reading on gauge.

c. Note the oil pressure.

(1) Normal oil pressure is approximately 35-40

psi with engine running. If normal oil pres-

sure is indicated, go to Step 4 of this test.

DC CONTROL

PART 3

Loading...

Loading...