SECTION

4:

GOVERNOR

CONTROLS

AND GOVERNOR

8. Slide the arm

in until the thrust washer is tight.

9. slidethelowerbushingdownand

intoitSholder,theninsirll

the upper e-clip.

ASSEMELE:

1. Clean any old

gasket

material from the crankcase

and

cover mating sudaces.

2.

Be sure thal the new oilpassage

o-ring is in

place.

3.

Put a

new

gasket

on the crankcase,

4. Slidethe

crankcase cover back on the crankcase.

Nol€:

Hold the

govemor

atm in

the counter-clo*wise

position

wlrile insta ing, Also, nldke

surc thatthe swing'

ing

an bhcket

goes

in

place.

5. Stan all of the crankcase

bolts, and then torque them to

35 ft.

lbs., following the

propertorque

sequence.

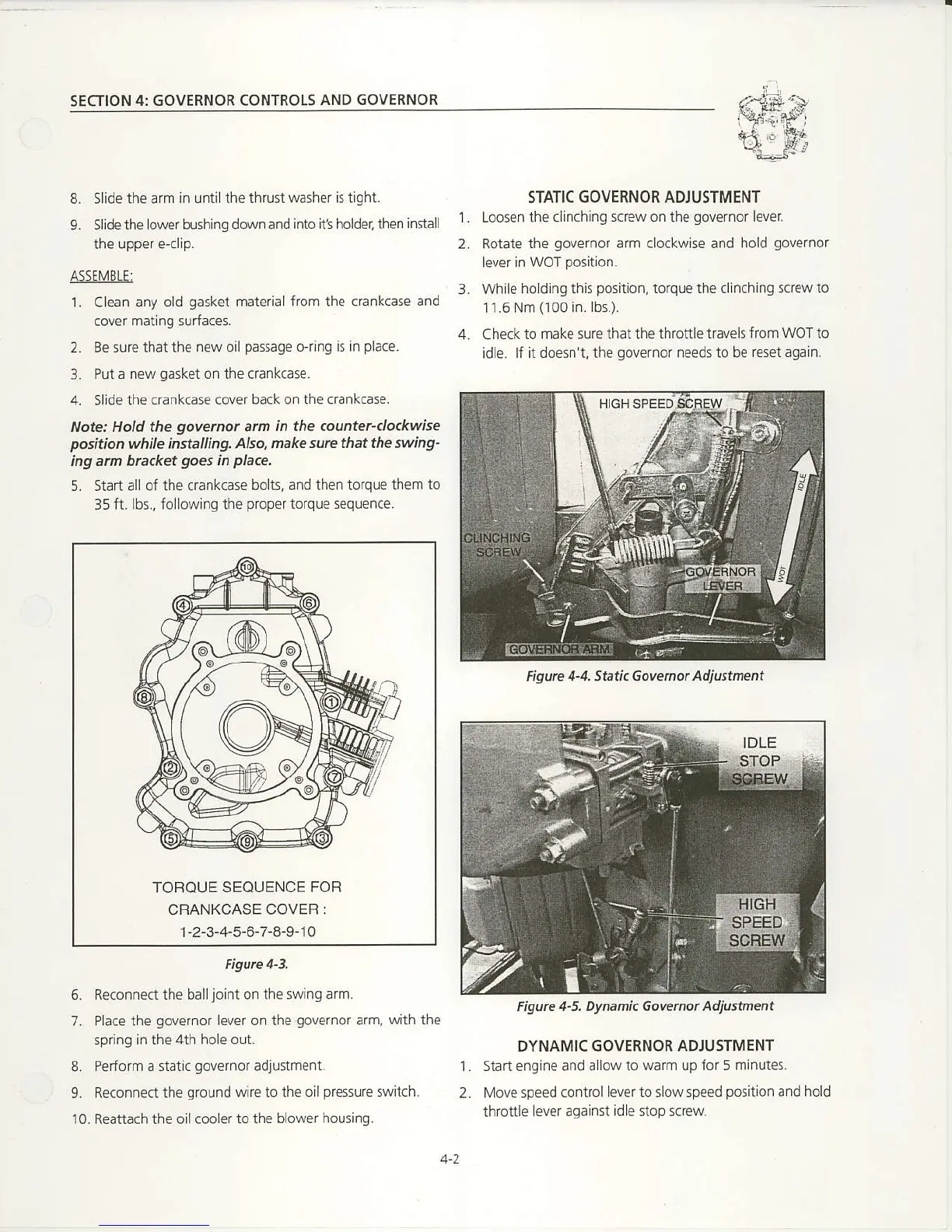

STATIC GOVERNOR ADIUSTMENT

Loosen the clinching

screw

on the

govemor

lever

Rotate

the

governor

arm clockwise and hold

governor

lever

in WOT

position.

While holding this

position,

torque the clinching screw to

11.6 Nm

(100

in.

Ibs.).

Check

to make sure that the throttle

travels from WOT to

idle.

lf it doesn't, the

governor

needs to be resetagain.

Figurc 4-5. Dynamic Govenor Adjustment

DYNAMIC GOVERNOR ADJUSTMENT

Slart engine and

a'bw 10 warr up fo 5 mi,rures.

Move speed

control lever to dowspeed

position

and hold

thrcttle

lever against idle nop scfew

1.

2.

L

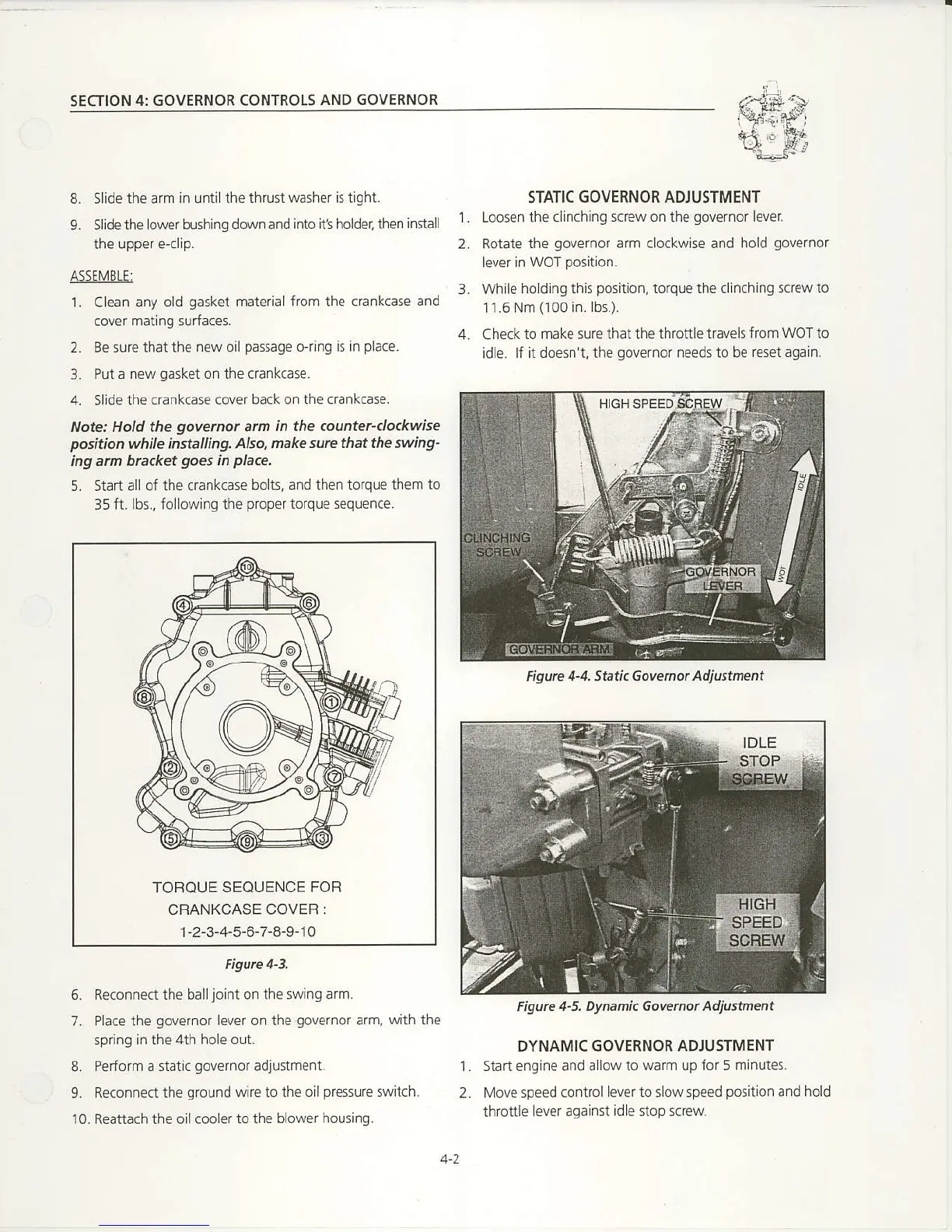

TOROUE

SEQUENCE FOR

CRANKCASE

COVEF :

1

-2-3-4-5-6-7-8-9-

1

0

Figurc 4-3,

5. Reconnect the ball

joint

on the swinq arm.

7- Place the

govenor

lever on the

governor

arm,

with the

spring in the 4th hole out.

8.

Perform a static

governor

adjustment.

9. Reconnectthe

ground

wire to the oilpressu€

switch.

10. Reattach the oil cooler to

Ihe blower

housing

t.

2.

Figurc 4-4, Sati. Gowmot Adjustnent

Loading...

Loading...