SECTION

'10:

CYLINDER & CRANKCASE

COVER

It is rccommended that the cylinde.

bores be reconditioned

to restore the cross

hatch when

new

piston

rlngs

are

to be

innalled in a cylinderthat iswithin specification.

Be careful not

to

hone ove6ize or itwillbe necessarv

to

reolace

the crankcase.

Honing

is

donewithava ablespeed L2",

podab

e drilland

a honing fixture. See

Page

l0-5 for dimensions

to make a

honing fixture. Use tlvo crankcase cover mounting

scrcws to

fasten the cr€nkcaseto the honing fixturc, Figure

10-5.

Clarnp honing fixture and crankcase securely

in a

vise

at a

convenient work height.

Plac-" hone in middle of cyllnder bore. Tlghten

adjusting

knob with

finger

untilstones

fit

snugly against

cylinder

wall.

DO NOT

FORCE.

Cut a

wood

block and

place

inside

rylinder

to

prevent

hone f.om exrending further than

3/4" to 1

'

(19

mm

to

25 mm) below cylinder

bore.

Place

hone

dive shaft

in

chuck of

portable

drill and tighten. Be sure that

cylinder and

hone are centered and aligned with the drilspindle.

NOTE:

To

produ.e

the

prcper

(oss

hatch finish use a dd

speed of apyoximately

2OO RPM

and

/P-60

Hatch nrckes

per

minvte.

Lubfi.ate hone

libera

y

to

prevent

build up

on finishing stones,

NOTE: Automatic transmission fluid is

an accebtable

honing oil. Another ac.eptabte honing oit

can be tnade

by mixing 4

patts

No. 30 weight oil with

I

patt

kercsene.

with hol running wat€r

Repeatwashing

and

rinsing unlilallt€ces

oi hon n9

grh

a€

gone.

Honing

git

is

highly

abGsive and

willcause rapid wearto all

ofthe lnternal components of the engine unless

ii is

completely

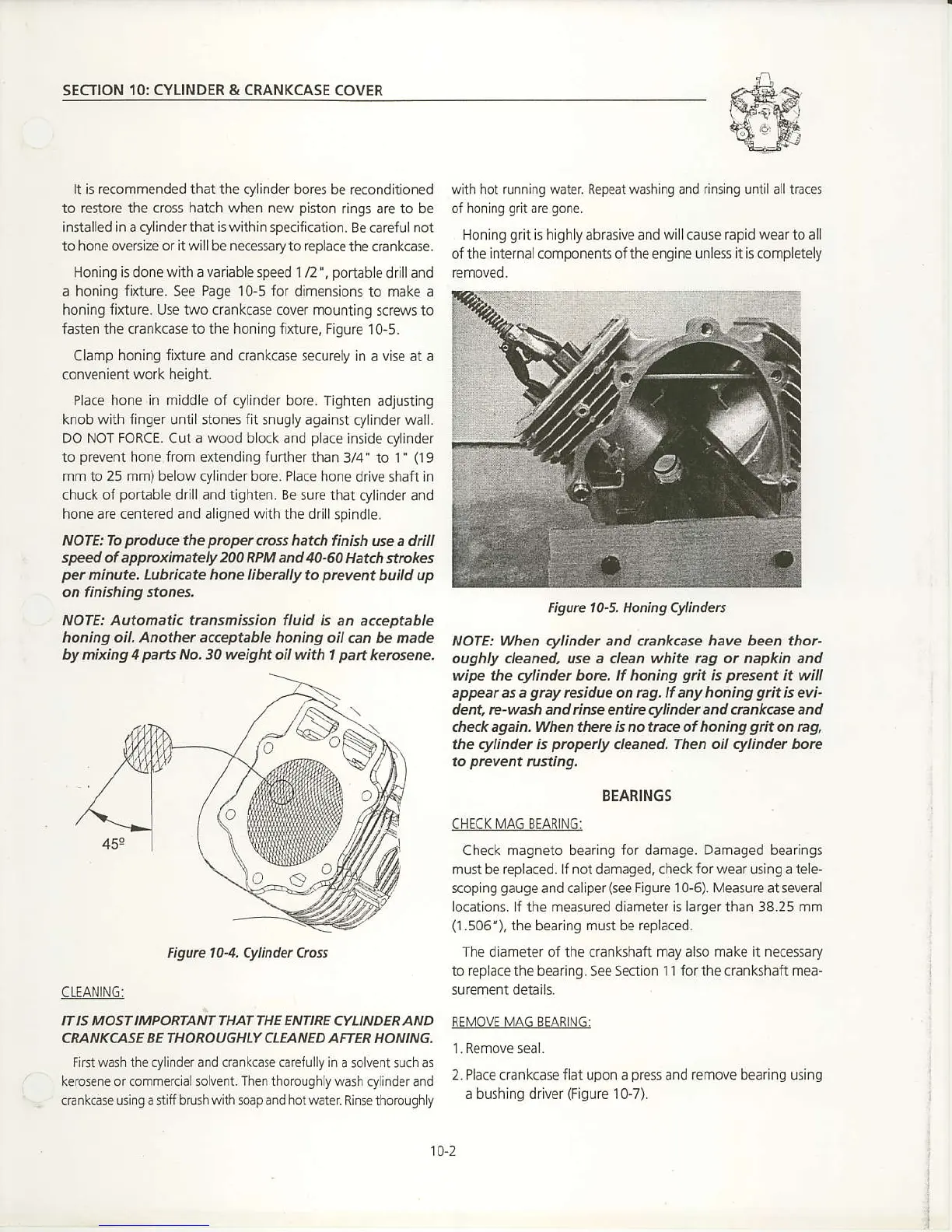

Figwe

| 0-4.

Cylinder Crcss

CLEANING:

IT IS MOST IMPORTANT

THAT THE ENTIRE

CYLINDER AND

CRANKCASE

BE THOROUGHLY CLEANED

AFIER HONING.

Finwash thecylinderand crankcasecareiully in

a solventsuch

as

kercsene or commeKlal solvent. Then thorough

ywash

cy

inder

afd

cGnkcase using a stiff brush

with

soap and

hotwater

Rinsethooughy

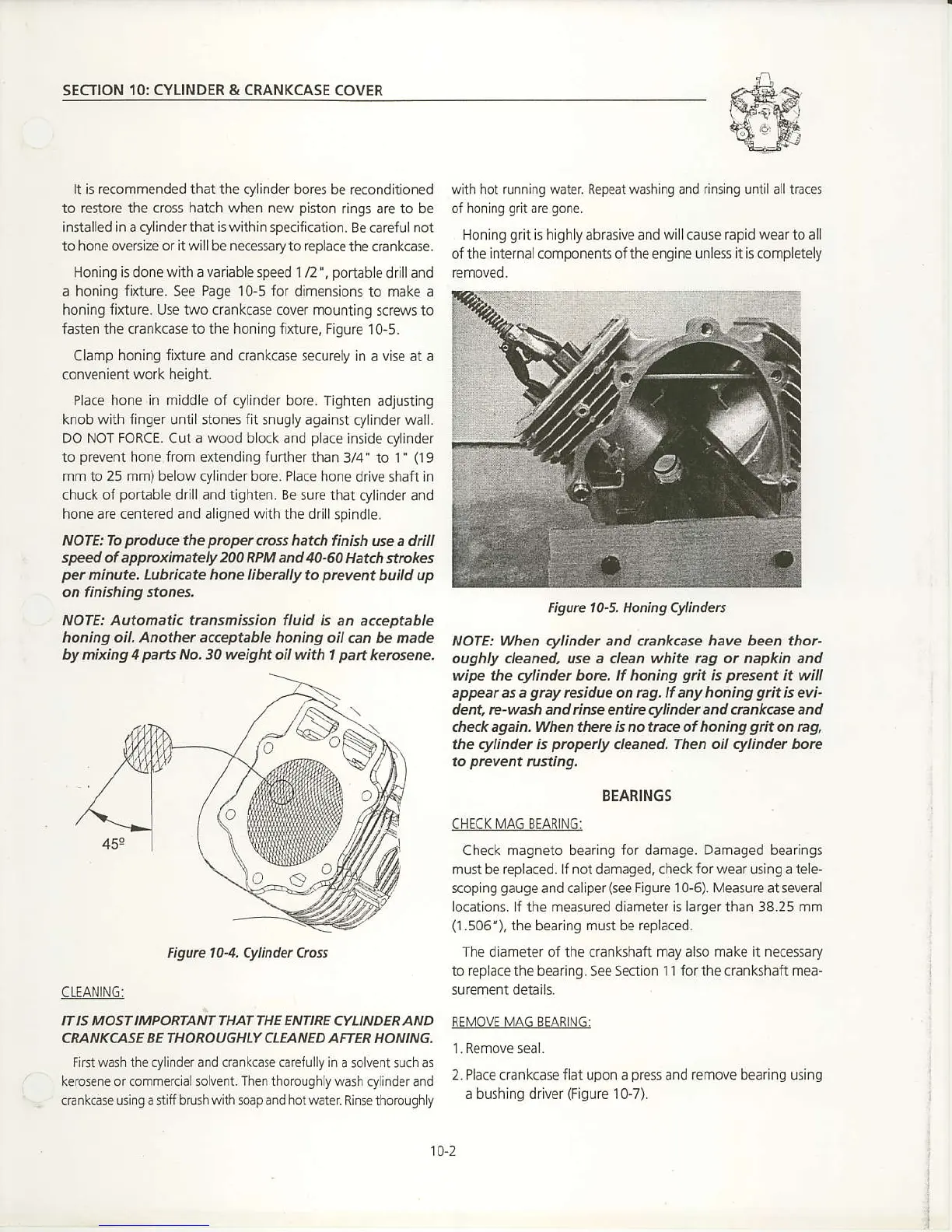

Figurc, 0- 5. Honing Cylinde6

NofE: when cylinder and .rankcase have been thor-

oughly cleaned, use a clean white ag or napkin and

wipe the cylinder borc. ff honing

grit

is

prcsent

it wi

appear as a

gEy

rcsidue on rag. lf any honing

gfit

is evi-

dent re-wash and dnse entirc

qlinder

and

(ankcase

and

.heck again. When therc is no tace of honing

gfit

on hg.

the

qtindet

is

$ope

y

cleaned. Then oil cylindet borc

to

pfevent

fusting,

BEARINGS

CHECK MAG BEAR]NG:

Check

magneto

bearing

for damage. Damaged bearings

must be replaced. Lf not daraaged, check

for wear

using a tele-

scoping

gauge

and calper

(see

Figure 10-6). Measure

atseveral

locations. lf the measured diameter is larger than 38.25 mm

(1.506"),

the bearing must be rcplaced.

The diameter of the crankshift may also make it necessary

to rep acethe bearing.see Secrion 11 forthe cfankshaft mea-

SuTement detars.

REMOVE IV1AG BEAR NG:

2.Placecrankcaseflat upon a

pressand

remove bearing

using

a bushlng driver

(Figure

10-7).

raN

,dffiW,r.'\r'4

10-2

Loading...

Loading...