5

2.5 CONNECTING START CIRCUIT WIRES

2.5.1 ON-SITE GENERATOR CONNECTIONS

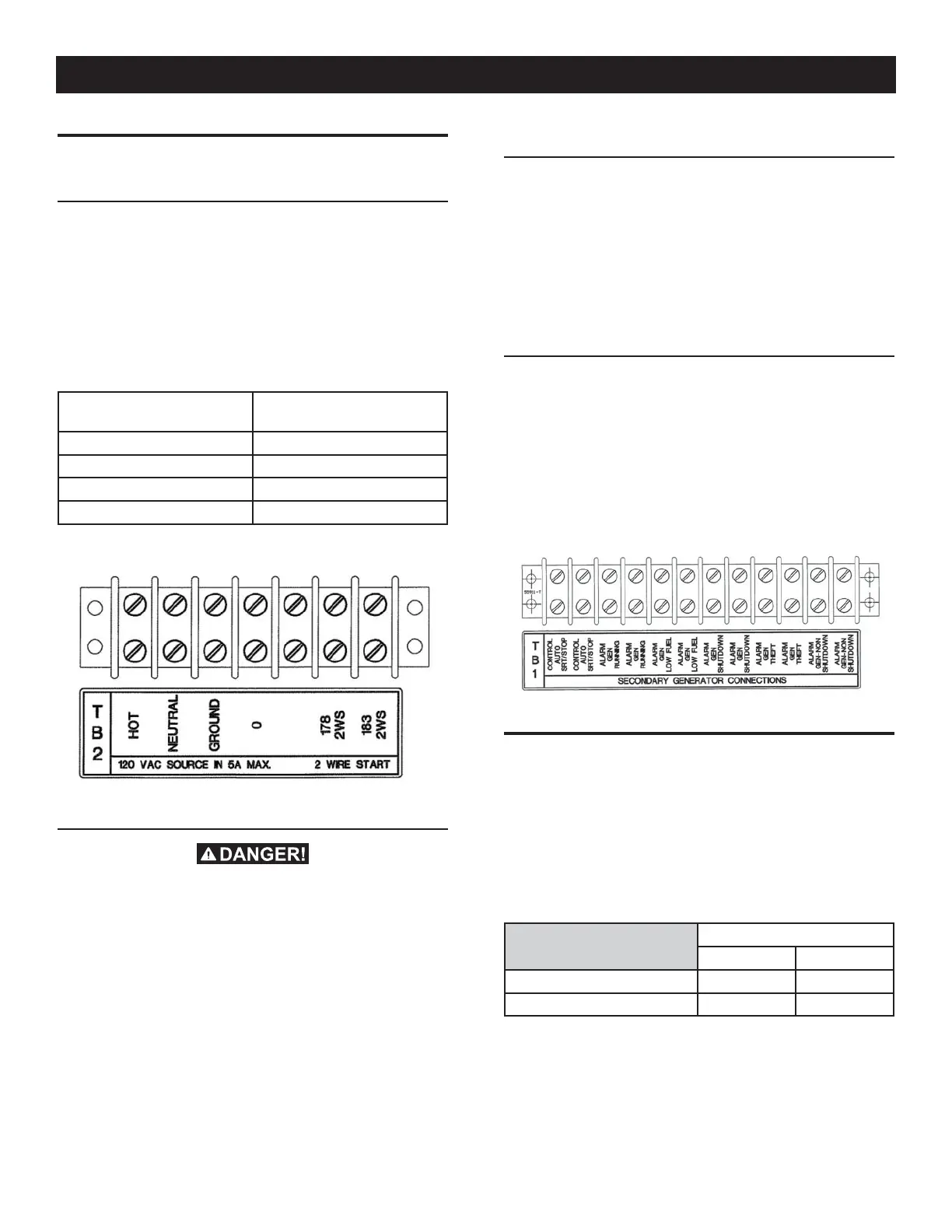

Connect suitable, approved wiring to transfer switch terminals

178 and 183 (see the following chart). Route these wires through

suitable, approved individual conduit and connect to identically

numbered terminals in the AC connection (lower) panel of the

generator set (see Figure 4).

Closure of Wire 178 and 183 circuit by switch circuit action must

result in generator engine cranking and startup.

Recommended wire gauge sizes for this wiring depends on the

length of the wire as recommended in the following chart:

MAXIMUM WIRE LENGTH

RECOMMENDED WIRE

SIZE

460 feet (140m) No. 18 AWG.

461 to 730 feet (223m) No. 16 AWG.

731 to 1,160 feet (354m) No. 14 AWG.

1,161 to 1,850 feet (565m) No. 12 AWG.

Figure 4 — On-site Generator Connections

2.5.2 BATTERY CHARGER CONNECTION (REQUIRED)

Disconnect all power from this unit before

making connections.

Connection steps (refer to Wiring Diagram 0J7612 on Generac

Website):

1. Ensure that utility power is OFF at this point.

2. Connect # 14 AWG (or larger) insulated wire (fused at the

source) with a 15A circuit maximum to terminals TB2-1,2,3

in the TAS and run this to the nearest 120 VAC single phase

critical load that will be supplied by the generator if utility

power is lost.

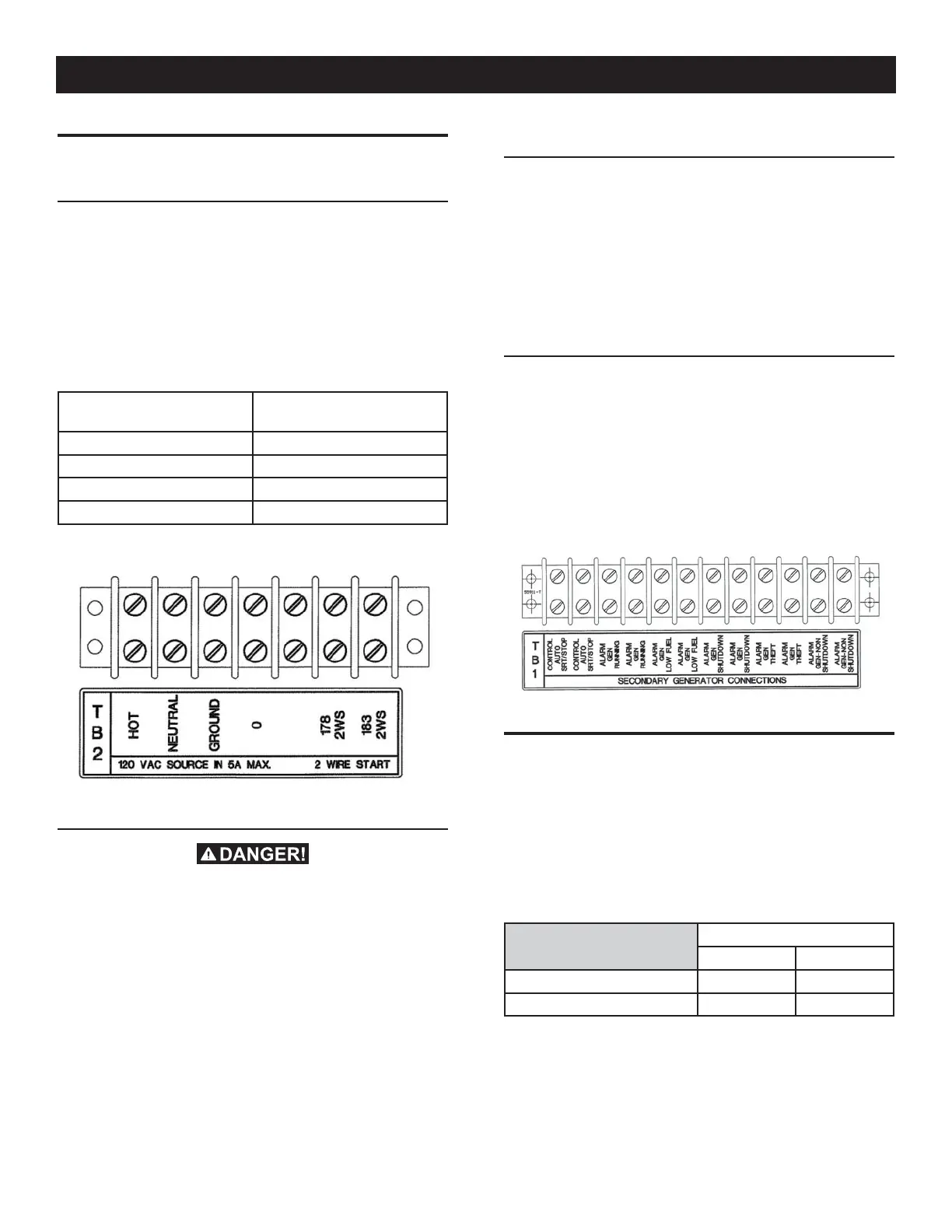

2.5.3 SECONDARY GENERATOR CONNECTIONS

The 2-wire start connections for the secondary generator are to be

made at the terminal blocks labeled "TB1 - Secondary Generator

Connections", the two terminals labeled "Control Auto Start/Stop".

This is typically done through a multi-wire cable to the secondary

generator.

Closure of the relay contacts across these terminals will occur

when the secondary generator is to run.

2.5.4 SECONDARY GENERATOR ANNUNCIATOR

CONNECTIONS

A terminal strip is provided to make the annunciator connections

from the Cam-lok box. A multi-conductor cable is provided with

the cam-lok enclosure (provided separately).

Route the multi-conductor cable into the TAS enclosure, be sure to

keep cable away from power leads. Secure in place using ty-wraps

or other appropriate fasteners. Connect the wires to the terminal

strip matching the functions declared on the terminal strip decal.

Figure 5 — Secondary Generator Connections

2.6 AUXILIARY CONTACTS

There is access to Auxiliary Contacts on the transfer switch to

operate customer accessories, remote advisory lights, or remote

annunciator devices. A suitable power source must be connected

to the COMMON (C) terminal. The contacts shown as FACTORY in

Figure 5 are connected at the factory for operating transfer switch

advisory lights. The contacts shown as auxiliary are available for

customer use.

Contact operation is shown in the following chart:

Switch Position

Utility Standby

Common to Normally Open Closed Open

Common to Normally Closed Open Closed

NOTE:

Auxiliary Contacts are rated 10 amps at 125 or 250 volts AC.

DO NOT EXCEED THE RATED VOLTAGE AND CURRENT OF THE

CONTACTS.

Installation

Loading...

Loading...