Do you have a question about the Glow-worm 24cx and is the answer not in the manual?

| Model | 24cx |

|---|---|

| Manufacturer | Glow-worm |

| Category | Boiler |

| Type | Combi |

| Output | 24 kW |

| CH Output (kW) | 24kW |

| Max Working Pressure | 3 bar |

| Dimensions | 740 x 418 x 300 mm |

| Fuel | Natural Gas |

Provides contact numbers for customer service, technical support, and sales enquiries.

Explains how to register the appliance for warranty and provides the registration hotline.

Details critical safety warnings, handling of metal parts, and sealed components.

Covers gas category, safety regulations, hazardous substances, and electrical supply.

Outlines compliance requirements for installation, gas supply, and water systems.

Explains boiler design aspects, safety devices, frost protection, and condensate handling.

Introduces the necessity of regular servicing and availability of spare parts.

Details technical specifications, dimensions, and hydraulic schematics of the boiler.

Specifies requirements for boiler placement, necessary clearances, and ventilation.

Describes various flue configurations and their required terminal positioning.

Covers sealed system filling, bypass, water treatment, and pressure requirements.

Provides instructions for wiring the appliance, including system controls and testing.

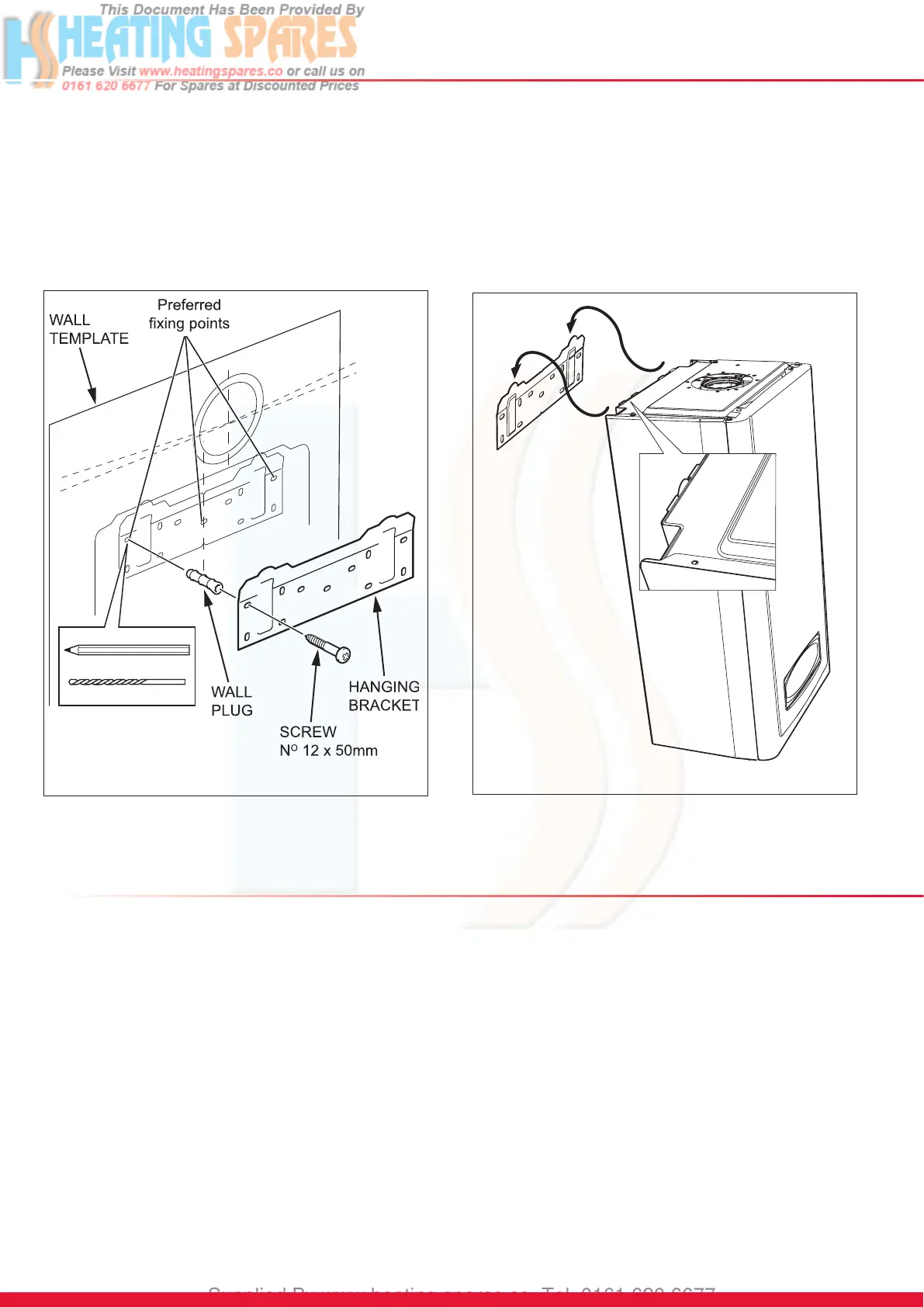

Details appliance packs, site requirements, fixing, and gas/water connections.

Details safe discharge valve installation and condensate drain connections.

Details steps for filling the heating circuit, water checks, and initial lighting.

Outlines general inspections, competency requirements, and combustion checks.

Explains fault codes, diagnostic menus, status codes, and troubleshooting steps.

Covers safety, draining, and general precautions before replacing appliance components.

Details replacement steps for major parts like gas valve, fan, burner, and heat exchanger.

Covers replacement of sensors, pumps, valves, PCBs, and interface modules.

Lists part numbers, descriptions, and GC part numbers for ordering spare components.

Provides recommendations for safe lifting and positioning of the appliance during installation.

States appliance compliance with relevant EU directives and European standards.