[page 20] | gpelectric.com

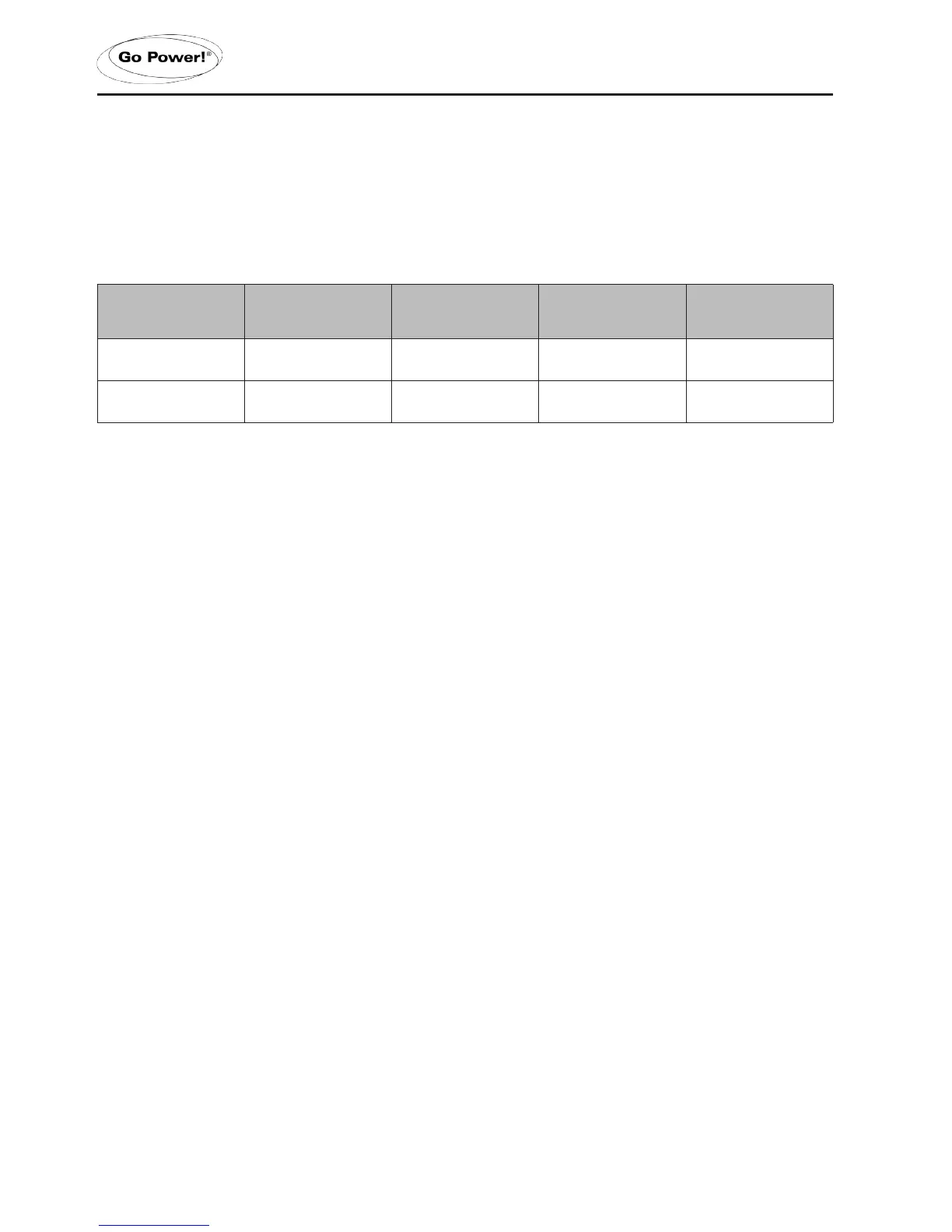

3.5.1 DC WIRE SIZING

ThedistancebetweenthebatterybankandtheInverter/Chargershouldbeasshortaspossibletoachievemaximumeciency

andtoreducerehazards.Thecablesshouldbeasshortaspossibleandtheoveralllengthofbothcablesaddedtogether

should be less than 10 ft (3m) to comply with code requirements. Keeping your wire runs as short as possible helps to prevent

low voltage shutdowns and nuisance tripping of the DC breaker because of increased current draw. The table below shows the

recommended DC cable size, fuses/circuit breakers, and DC grounding cable sizes for the IC Series (Note: these values are

correct for cables in free air, not conduit)

DC Cable Size

Inline Fuse/Circuit

Breaker

Overall Length of

Positive and Negative

Cable combined

Recommended

Go Power! DC Kit

DC Grounding Cable

Size

No. 2/0 AWG 300A Class T 5 ft (1.5m) #4 No. 6 AWG

No. 4/0 AWG 400A Class T 10 ft (3m) #5 No. 6 AWG

3.5.2 DC OVERCURRENT PROTECTION AND DC DISCONNECT

Batteries are capable of providing very large currents in case of a short circuit. If this occurs with no DC overcurrent protection,

itwillresultinoverheatingandmeltingofthecablesandpossiblyseriousinjuryand/orre.

DC overcurrent protection is not included with the IC Series. It must be installed between the Inverter/Charger and battery bank

for safety reasons and to comply with code regulations.

Use a very fast acting DC fuse or circuit breaker in the positive cable, the fuse should be installed as close to possible to the

battery positive terminal. Ideally the fuse/circuit breaker should be installed within 18” (45cm of the battery). The fuse required

for DC Cable lengths up to 5ft is detailed in the above table.

Inallinstallationsabatterydisconnectswitchisrequired.Ifyouinstallacircuitbreakerforovercurrentprotectionthiswillsuce

as a disconnect switch. If you install a fuse for overcurrent protection, then a separate disconnect switch will need to be installed.

3.5.3 PREPARING THE DC CABLES

Go Power! supplies 2 ring lugs with the IC Series, which can be used for the Inverter/Charger end of the DC Cables. Source the

correct ring terminals for the batteries you are using.

• Cut the negative and positive cables to the required length.

• Stripoenoughinsulationsoyoucaninstalltheringlugsprovided.

• Use the correct crimp connector to install the ring lugs.

•

Attach the connectors to both ends of both cables. Make sure no stray wire strands protrude from the connectors.

3.5.4 DC CABLE CONNECTIONS

When installing the battery cable ring lug onto the Inverter/Charger DC terminal and the battery post, do not put anything between

the ring lug and the metal surface. Incorrectly installed hardware causes a high resistance connection which could lead to poor

Inverter/Chargerperformanceandmaymeltthecableandterminalconnections.Refertoguresonpage21toconnectthe

DC Cables and to install the hardware correctly. Use a 13mm wrench or socket to tighten the M8 x 1.25mm Nuts. Tighten the

terminal connections securely. Periodically check the connections to make sure they remain tight and secure.

To help prevent seizing and corrosion around the terminals, the use of an anti-seize lubricant is highly recommended. Apply the

antioxidant grease or spray after all the connections are made and tightened.

INSTALLATION

Loading...

Loading...