90

6.6 SEAT

Lengthwise adjustment: with lever n.11 fig.1.

Seat firmness adjustment: with knob n.14 fig.1.

The following adjustments are possible for CE certificated seated:

• Lever 27 fig.1 - seat height adjustment.

• Lever 28 fig.1 - seat firmness adjustment for driver weight: less than 70 kg;

over 70 kg.

6.7 WHEELS

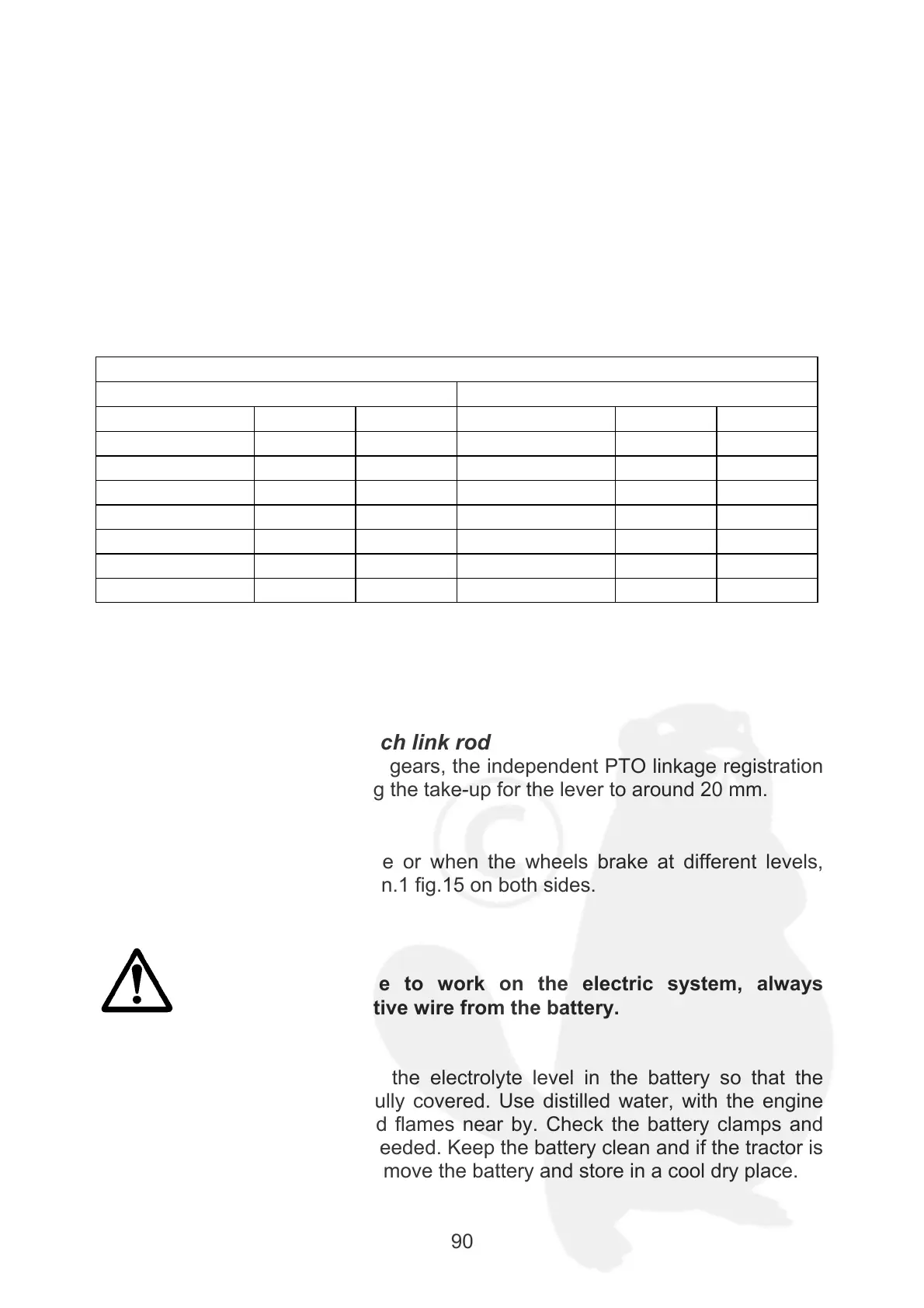

TYRE INFLATION PRESSURE

Front Rear

Tyres Bar Kpa Tyres Bar KPa

6x12" 1,9 190 250/80x18" 2,0 200

6.5/80x12" 2,0 200 260/80x20" 1,6 160

7.00x12" 2,0 200 12.4R20" 1,6 160

23-8.50x12" 1,5 150 33-12.50x15" 1,4 140

6x12"FD 2,0 200 9.5x18"FD 2,2 220

8.00x20" 1,7 170

8.3x24" 3,1 310

6.8 REGISTRATIONS

6.8.1 Transmission clutch link rod

When the pedal take-up is less than 20 mm, regulate it with register n.1 fig.10.

6.8.2 Independent PTO clutch link rod

With tractors with synchronized gears, the independent PTO linkage registration

is done on fork n.2 fig.11, bring the take-up for the lever to around 20 mm.

6.8.3 Brake link rod

When pedal travel is excessive or when the wheels brake at different levels,

adjust the nuts on the link rods n.1 fig.15 on both sides.

6.9 ELECTRIC SYSTEM

Whenever you have to work on the electric system, always

disconnect the positive wire from the battery.

- Battery

Check and top up as needed the electrolyte level in the battery so that the

battery elements are always fully covered. Use distilled water, with the engine

switched off and without naked flames near by. Check the battery clamps and

grease them with vaseline as needed. Keep the battery clean and if the tractor is

to be inactive for a long time, remove the battery and store in a cool dry place.

Loading...

Loading...