Maintenance

Pump Pump

Pump

Lubrication Lubrication

Lubrication

System System

System

ChecktheconditionoftheISOpumplubricantdaily.

Changethelubricantifitbecomesagel,itscolor

darkens,oritbecomesdilutedwithisocyanate.

Gelformationisduetomoistureabsorptionbythe

pumplubricant.Theintervalbetweenchanges

dependsontheenvironmentinwhichtheequipment

isoperating.Thepumplubricationsystemminimizes

exposuretomoisture,butsomecontaminationisstill

possible.

Lubricantdiscolorationisduetocontinualseepageof

smallamountsofisocyanatepastthepumppackings

duringoperation.Ifthepackingsareoperating

properly,lubricantreplacementduetodiscoloration

shouldnotbenecessarymoreoftenthanevery3or

4weeks.

Tochangepumplubricant:

1.FollowPressureReliefProcedure,page62.

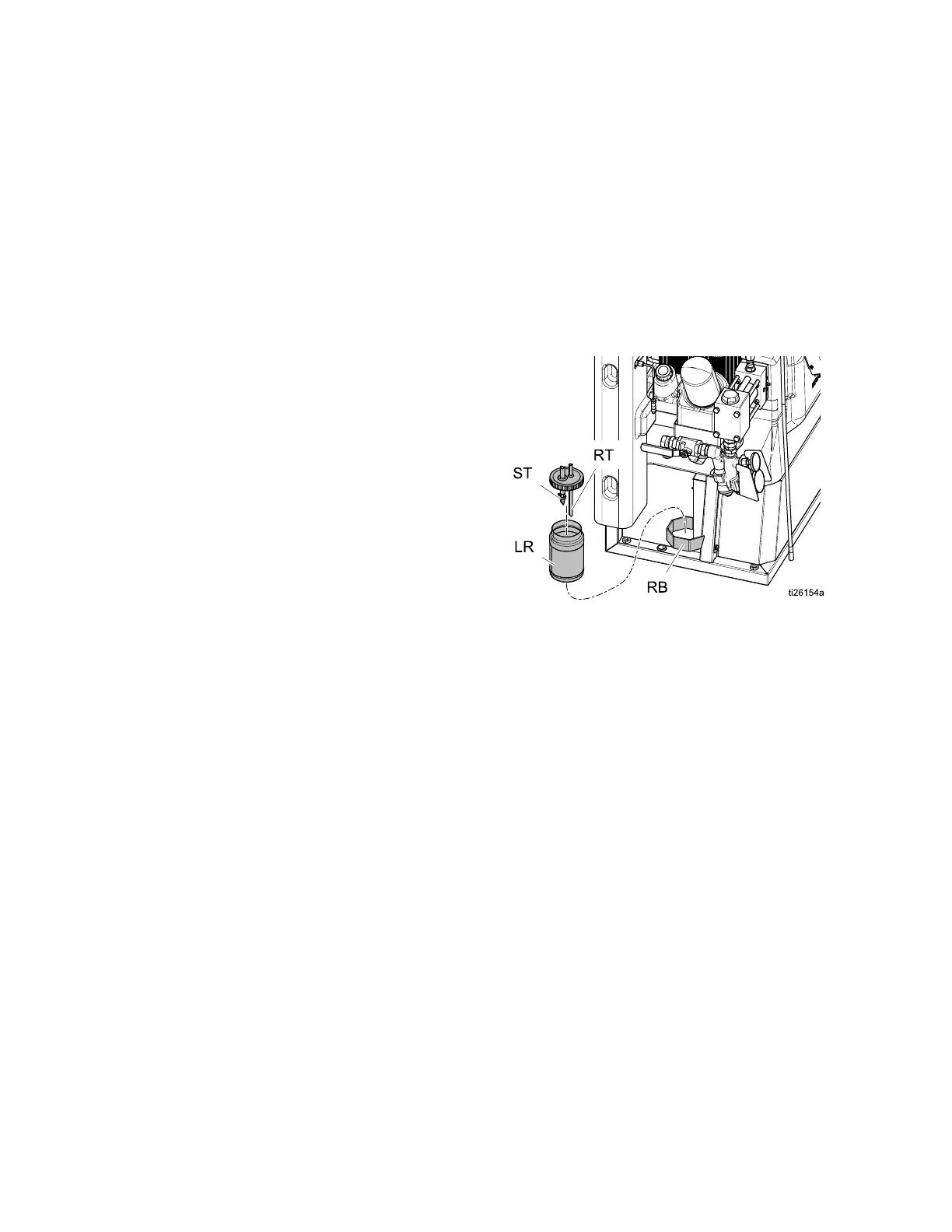

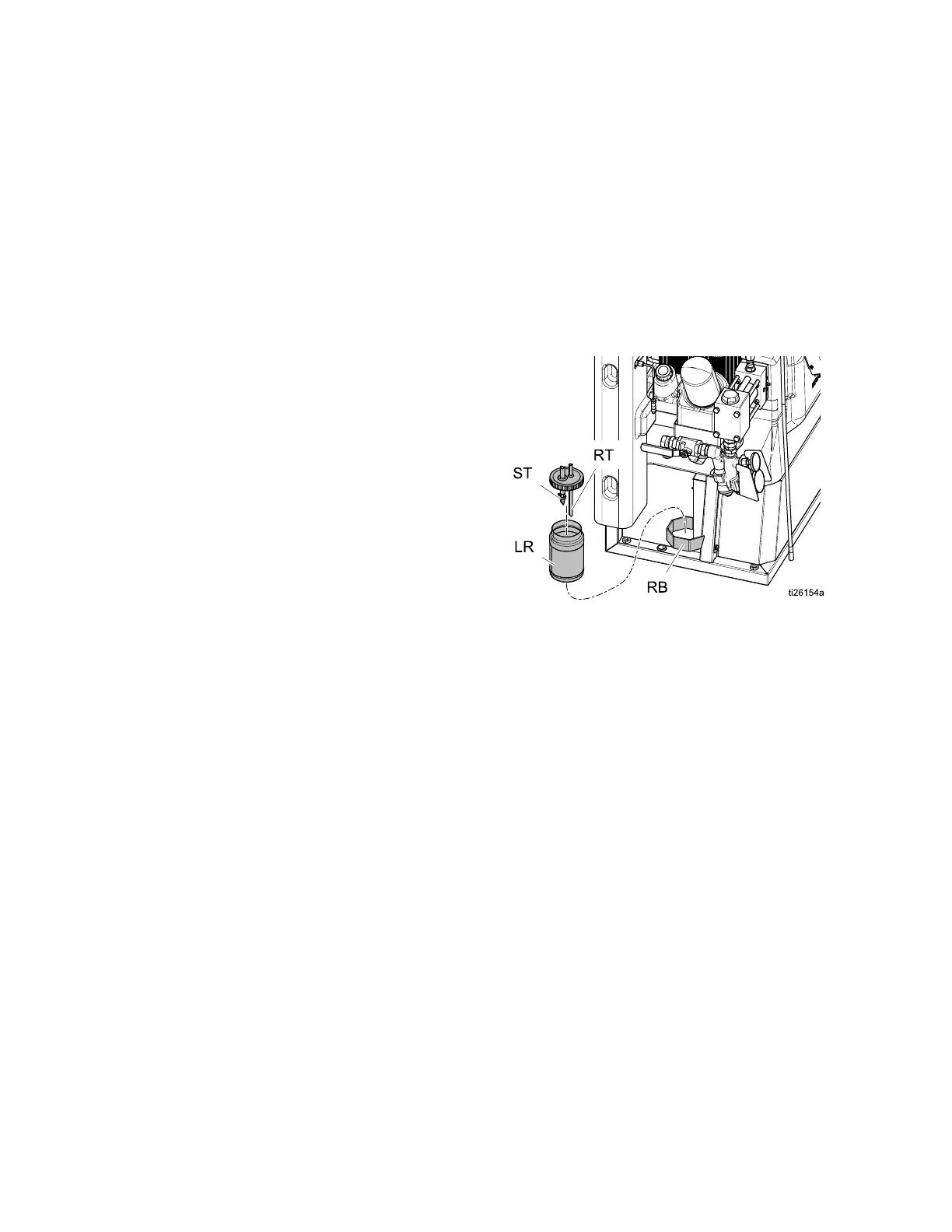

2.Liftthelubricantreservoir(LR)outofthebracket

(RB)andremovethecontainerfromthecap.

Holdingthecapoverasuitablecontainer,remove

thecheckvalveandallowthelubricanttodrain.

Reattachthecheckvalvetotheinlethose.

3.Drainthereservoirandushitwithclean

lubricant.

4.Whenthereservoirisushedclean,llwithfresh

lubricant.

5.Threadthereservoirontothecapassemblyand

placeitinthebracket.

6.Pushthelargerdiametersupply(ST)tube

approximately1/3ofthewayintothereservoir.

7.Pushthesmallerdiameterreturntube(RT)into

thereservoiruntilitreachesthebottom.

NOTE: NOTE:

NOTE:

Thereturntubemustreachthebottomof

thereservoirtoensurethatisocyanatecrystals

willsettletothebottomandnotbesiphonedinto

thesupplytubeandreturnedtothepump.

8.Thelubricationsystemisreadyforoperation.No

primingisrequired.

PumpLubricationSystem

Figure11

66 334945J

Loading...

Loading...