Temperature Control Diagnostic Codes

12 3A1570V

NOTE: Before doing the following checks, note which

zone (A, B, FTS, or all) has high fluid temperature.

5. Verify fluid temperature, using an external

temperature sensing device.

6. If temperature is too high (sensor reading is

229°F [109°C] or above), check if thermocouples A

and B are damaged, or not contacting the heater

element. See Thermocouple, page 33.

7. To test that temperature control module turns off

when equipment reaches temperature setpoint:

a. Set temperature setpoints far below displayed

temperature.

b. Turn zone on. If temperature rises steadily,

power module is failing.

c. Verify by swapping with another power module.

See Replacing Temperature Control

Assembly Modules, page 30.

d. If the swapped module does not fix the problem,

the power module is not the cause.

8. Verify continuity of heater elements with an

ohmmeter, see Primary Heater, page 31.

E02: High zone current

1. Turn main power OFF .

2. Follow the Pressure Relief Procedure, page 15.

NOTE: Disconnect whip hose.

3. Disconnect hose connector (D) at Reactor.

4. Using an ohmmeter, check between the two

terminals of the connector (D). There should be no

continuity.

5. Exchange zone module with another one. Turn

zone on and check for error (see Replacing

Temperature Control Assembly Modules, page

30). If error disappears, replace faulty module.

For hose zone: If error still occurs, perform

Transformer Primary Check and Transformer

Secondary Check, starting on page 37.

NOTE: When there is a high current error, the LED on

that zone’s module will turn red while the error is

displayed.

E03: No zone current

1. Check for tripped circuit breaker inside electrical

cabinet or at power source for that zone. Replace

circuit breaker if it trips habitually.

2. Check for loose or broken connection at that zone.

3. Exchange zone module with another one. Turn

zone on and check for error (see Replacing

Temperature Control Assembly Modules, page

30). If error disappears, replace faulty module.

4. If E03 occurs for all zones, the 238CR contactor

may not be closing. Verify wiring from heater control

to contactor coil.

a. Hose zone: test hose continuity, page 34.

b. Perform Transformer Primary Check and

Transformer Secondary Check, starting on

page 37.

NOTE: When a no current error occurs, the LED on this

specific zone’s module turns red when the error is

displayed.

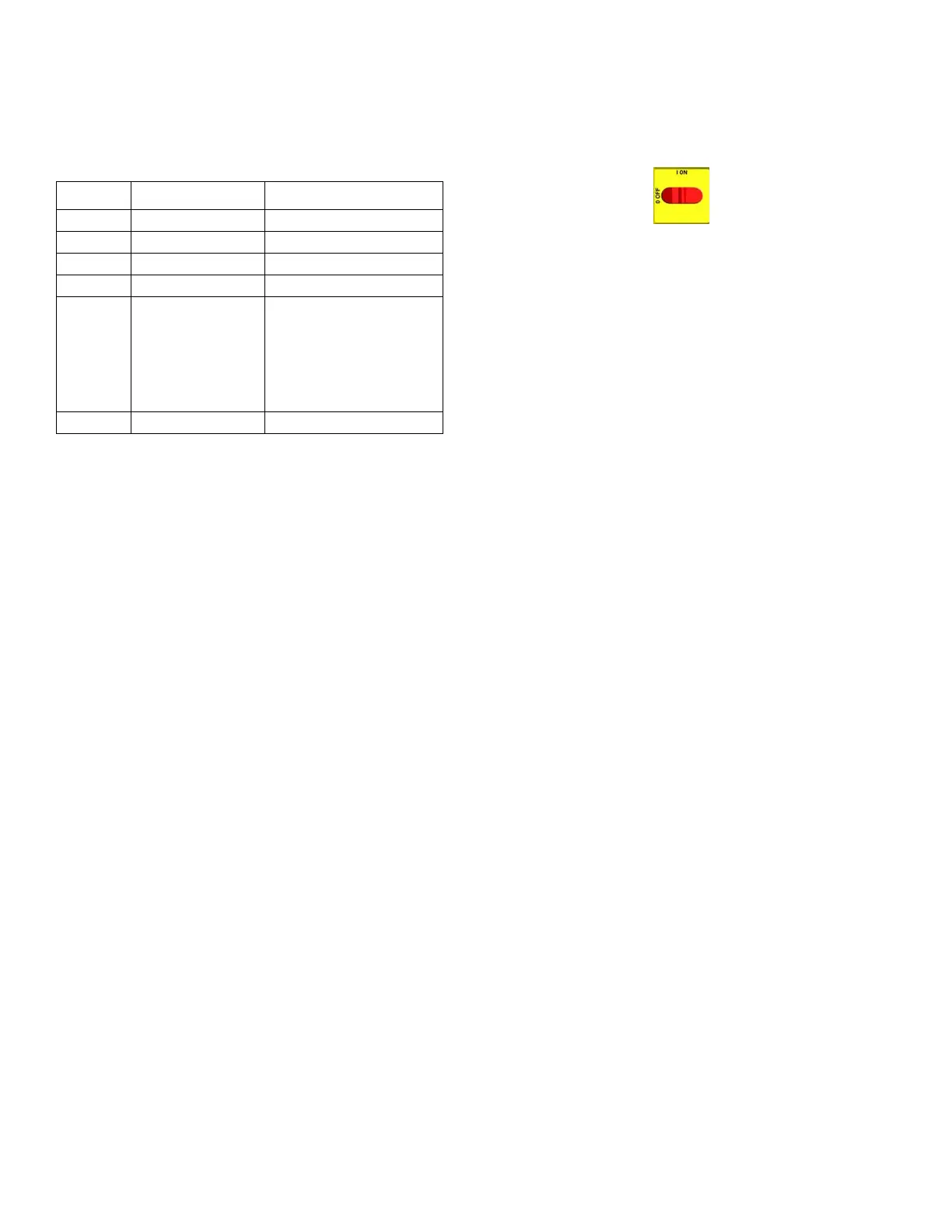

Table 1: Sensor Connector Continuity

Checks

Pins Description Reading

1 & 2 OT switch nearly 0 ohms

3 & 4 Jumpered nearly 0 ohms

5 & 6 Thermocouple A 4-6 ohms

8 & 9 Thermocouple B 4-6 ohms

11 & 12 FTS approximately 35

ohms per 50 ft (15.2

m) of hose, plus

approximately 10

ohms for FTS at 70°F

(21°C)

10 & 12 FTS open

Loading...

Loading...