Repair

3A1570V 39

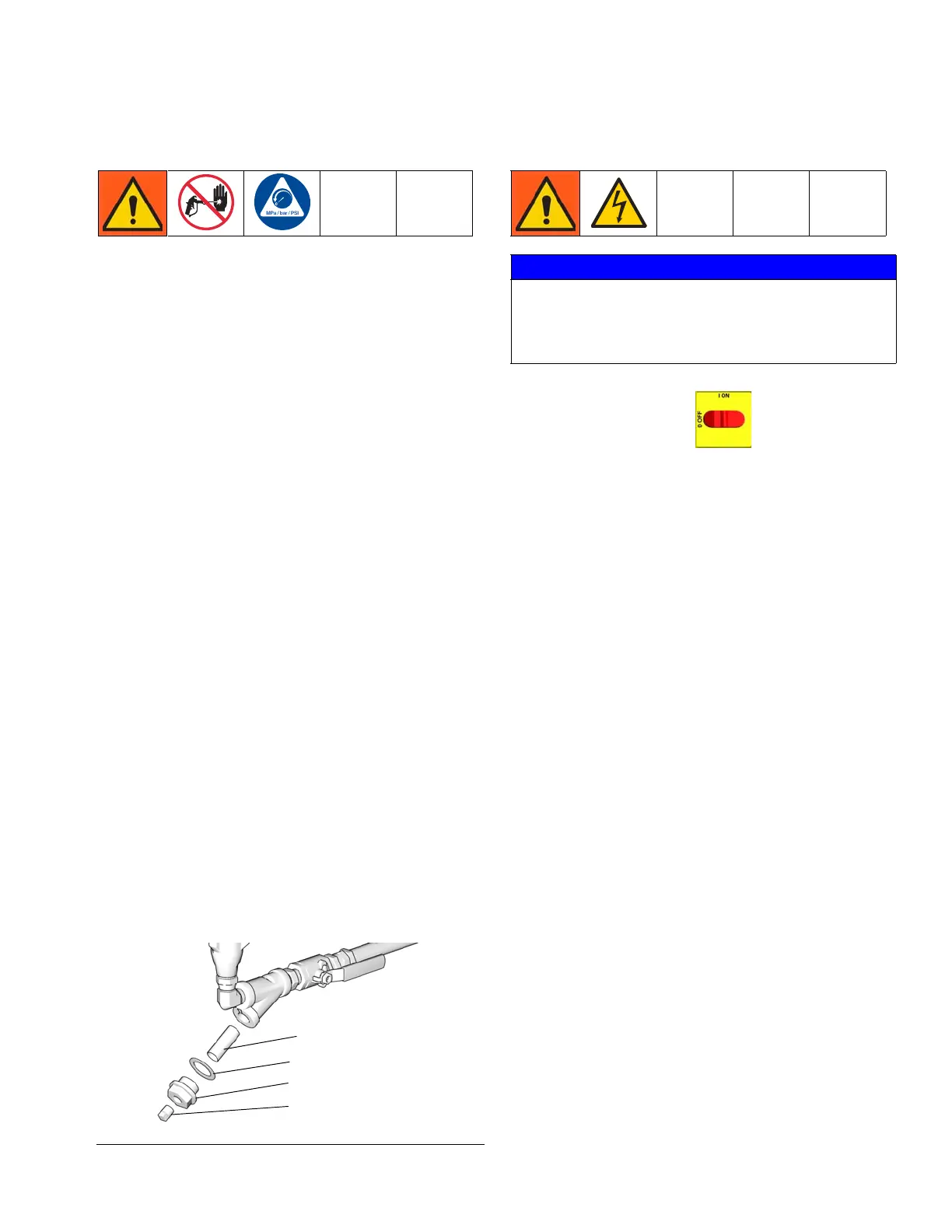

Fluid Inlet Strainer Screen

The inlet strainers filter out particles that can plug the

pump inlet check valves. Inspect the screens daily as

part of the startup routine, and clean as required.

Isocyanate can crystallize from moisture contamination

or from freezing. If the chemicals used are clean and

proper storage, transfer, and operating procedures are

followed, there should be minimal contamination of the

A-side screen.

NOTE: Clean the A-side screen only during daily

startup. This minimizes moisture contamination by

immediately flushing out any isocyanate residue at the

start of dispensing operations.

1. Close the fluid inlet valve at the pump inlet and shut

off the appropriate feed pump. This prevents

material from being pumped while cleaning the

screen.

2. Place a container under the strainer base to catch

drain off when removing the strainer plug (C).

3. Remove the screen (A) from the strainer manifold.

Thoroughly flush the screen with compatible solvent

and shake it dry. Inspect the screen. No more than

25% of the mesh should be restricted. If more than

25% of the mesh is blocked, replace the screen.

Inspect the gasket (B) and replace as required.

4. Ensure the pipe plug (D) is screwed into the strainer

plug (C). Install the strainer plug with the screen (A)

and gasket (B) in place and tighten. Do not

overtighten. Let the gasket make the seal.

5. Open the fluid inlet valve, ensure that there are no

leaks, and wipe the equipment clean. Proceed with

operation.

Temperature Display

1. Turn main power OFF . Disconnect power

supply.

2. Follow the Pressure Relief Procedure, page 15.

3. Refer to Wiring Schematics, page 55.

4. Put on static conductive wrist strap.

5. Disconnect main display cable (106) at lower left

corner of display module; see F

IG

. 17, page 40.

6. Remove screws (116) and cover (105); see F

IG

. 17,

page 40.

7. Disconnect cable connector from back of

temperature display (102). See F

IG

. 17.

8. Disconnect ribbon cable(s) (R) from back of display;

see F

IG

. 17, page 40.

9. Remove nuts (103) and plate (101).

10. Disassemble display, see detail in F

IG

. 17, page 40.

11. Replace board (102a) or membrane switch (102b)

as necessary.

12. Move jumper (119) to J1 on replacement display

board. See F

IG

. 17.

13. Reassemble in reverse order, see F

IG

. 17, page 40.

Apply medium strength thread sealant where

shown. Be sure display cable ground wire (G) is

secured between cable bushing and cover (105)

with screws (107).

F

IG

. 16: Fluid Inlet Strainer

NOTICE

Before handling board, put on static conductive wrist

strap to protect against static discharge which can

damage assembly. Follow instructions provided with

wrist strap.

Loading...

Loading...