10

Oil Storage &

Supply System

3 Oil Storage & Supply System

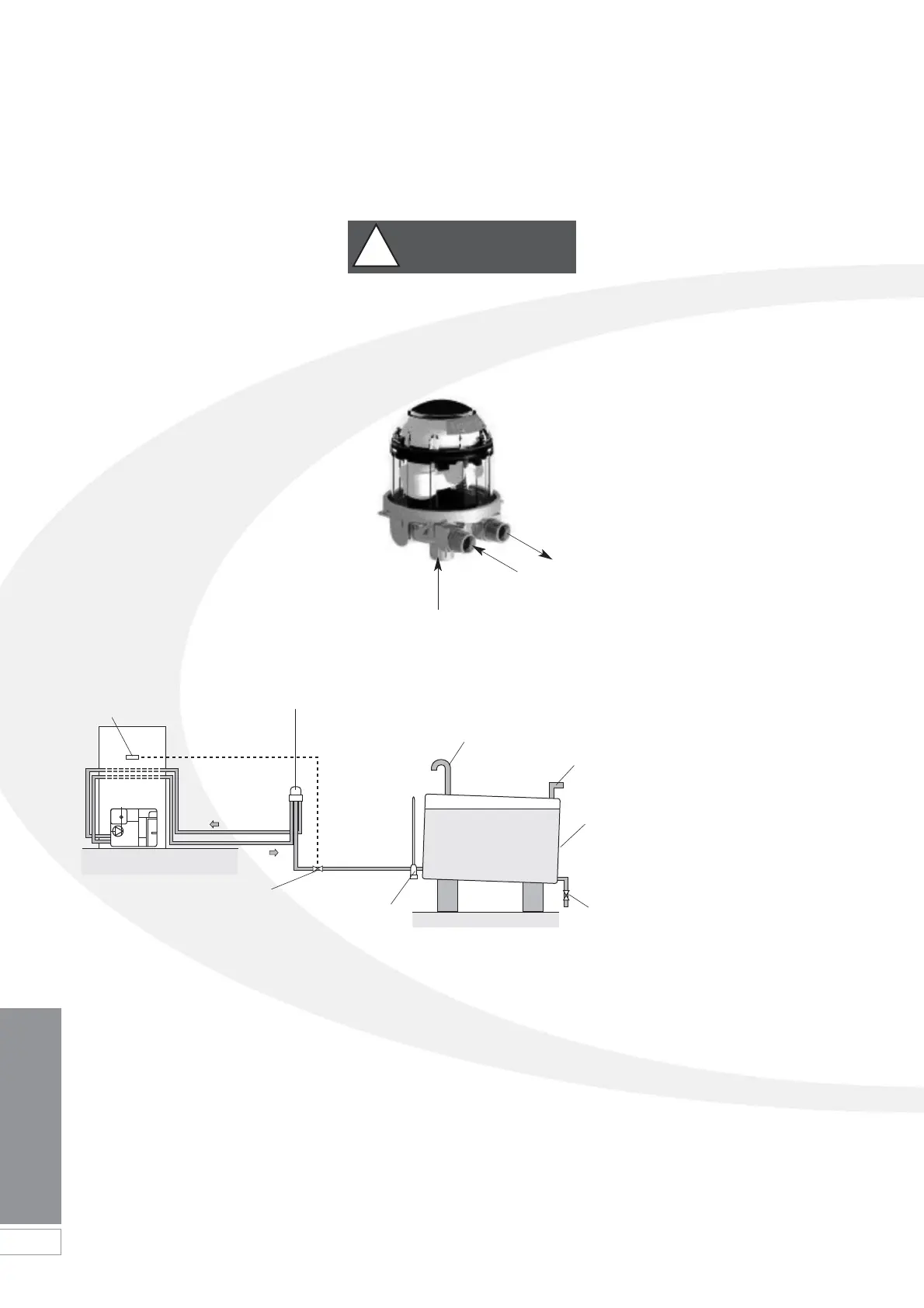

Tiger Loop System

When The storage tank is below the

burner, an alternative to a two pipe

system can be achieved using a ‘Tiger

Loop’ type oil de-aerator. This effectively

removes the air from the oil supply on a

single pipe lift.

The de-aerator is connected close to

the boiler as a two pipe system (omitting

the non-return valve) as shown in Fig.

3-3. Refer to the manufacturer’s

instructions supplied with the de-

aerator. The de-aerator must be

mounted vertically, as shown in Figures

3-3 and 3-4.

To be used with a Tiger Loop system,

the burner must be fitted with an

additional flexible fuel line (a flexible fuel

line (900mm) and

3

/8” to

1

/4” BSP male

adaptor are available to purchase from

Grant Engineering (UK) Limited - Part

No. RBS36).

To prevent any possibility of fuel

fumes entering the boiler, the de-

aerator must be fitted outside the

casing.

!

WARNING

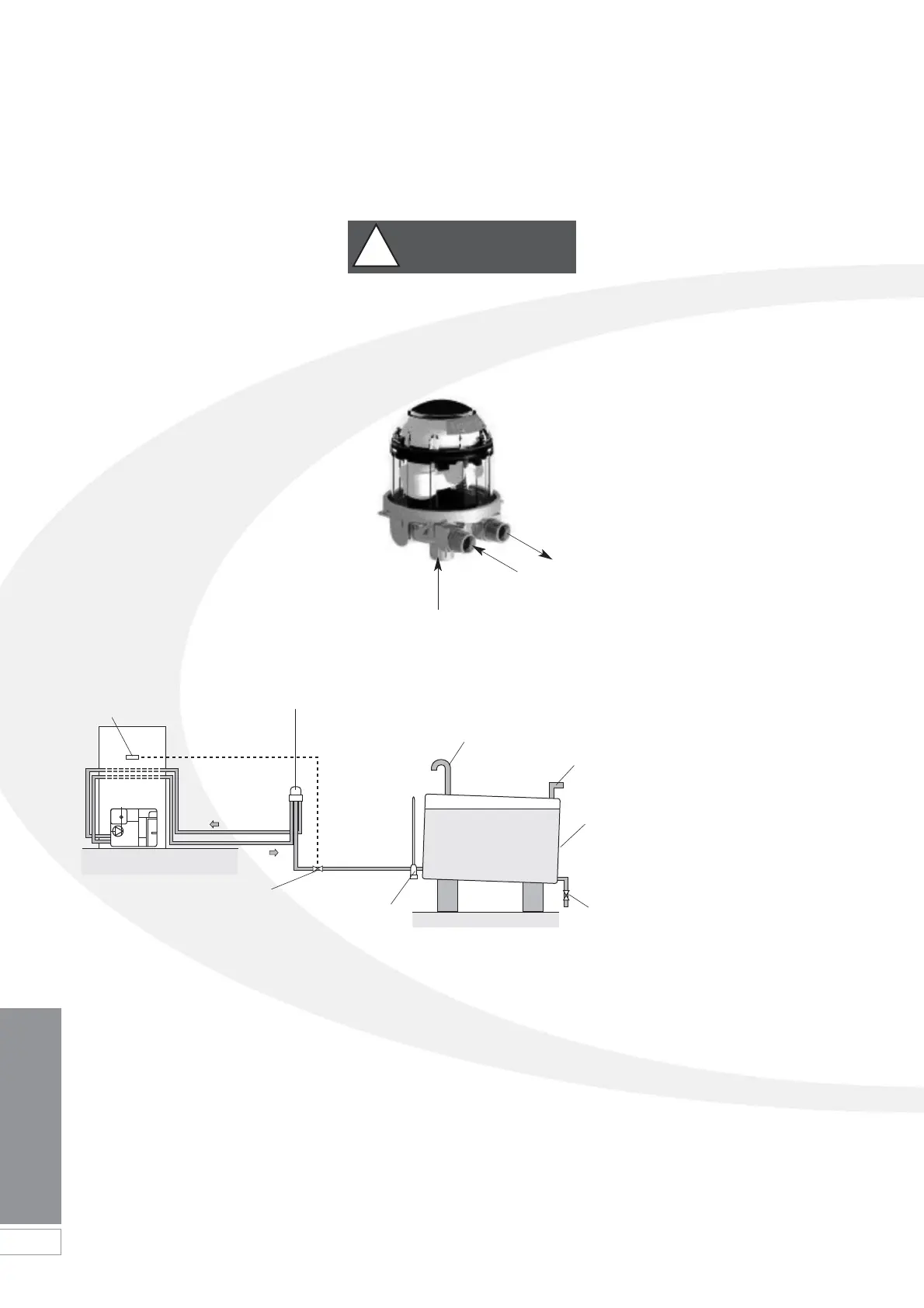

Figure 3-4: Tiger loop de-aeration device

To burner

From burner

From tank

Figure 3-3: De-aeration device system

Fire valve

Supply

Return

Fire valve sensor

Vent pipe

Fill pipe

Sludge

valve

Tankmaster

Fuel

storage

tank

De-aeration device e.g

Tiger Loop see Figure 3-4

Pump (see section 3.2)

Loading...

Loading...