Pipe Connections

15

5 Pipe Connections

5.1 Water Connections

The pipework can exit the boiler

enclosure through the pre-cut openings

provided in either side panel to pass

through the wall when installed against

the building. The side flue exit openings

may also be used to route the pipework

and cables through the casing sides

and into the building. See Section 2.5.

A spare blanking plate with a 112mm

diameter hole is supplied with the Vortex

Pro Combi e boilers.

This is intended to provide an opening

into the boiler if a 110mm soil pipe is

used as a pipe duct through the wall.

Alternatively for free standing

installations, pipework can be routed

down and through the pre-cut openings

provided in the base of the enclosure,

to be run underground to the building.

See Section 2.5.

Flow and return connections -

All models are supplied with a push-fit

elbow connection for the heating flow

and return - 22mm (Vortex Pro Combi

21e and 26e) or 28mm (Vortex Pro

Combi 36e).

Hot water connections - All models

are supplied with push-fit elbow

connections for the cold water mains

inlet pipe and hot water outlet pipe.

These are 15mm for the Vortex Pro

Combi 21e and 26e, and 22mm for the

Vortex Pro Combi 36e.

All pipes to be fitted into the push-fit

connectors provided should be cut

using a pipe slicer or pipe cutter - to

leave the pipe ends with a slight

radius and free from any burrs or

sharp edges.

Pipes to be used with these fittings

should not be cut square using a

hacksaw.

!

CAUTION

A drain tap is provided at the bottom on

the front of the boiler (and also on the

hot water store on the Vortex Pro

Combi).

5.2. Making the Water

Connections

Flow and return pipework can be routed

to either side of the boiler, whichever is

adjacent to the building, from the push-

fit elbows (supplied) on the flow and

return connection. Refer to Figure 5-1.

Holes are provided at the base of the

casing side panels to allow the

condensate pipe to be run through at

the rear of the boiler. It will be necessary

to remove the back panel from the

boiler casing to fit this pipework.

All Models

A 15mm discharge pipe must be

connected to the safety valve outlet

connection. The pipework between the

safety valve and the boiler must be

unrestricted, that is, no valves. The

discharge pipe should be run to the

outside of the boiler casing, through

one of the openings provided at the

base of each side panel, and terminate

so that it cannot cause injury to persons

or property.

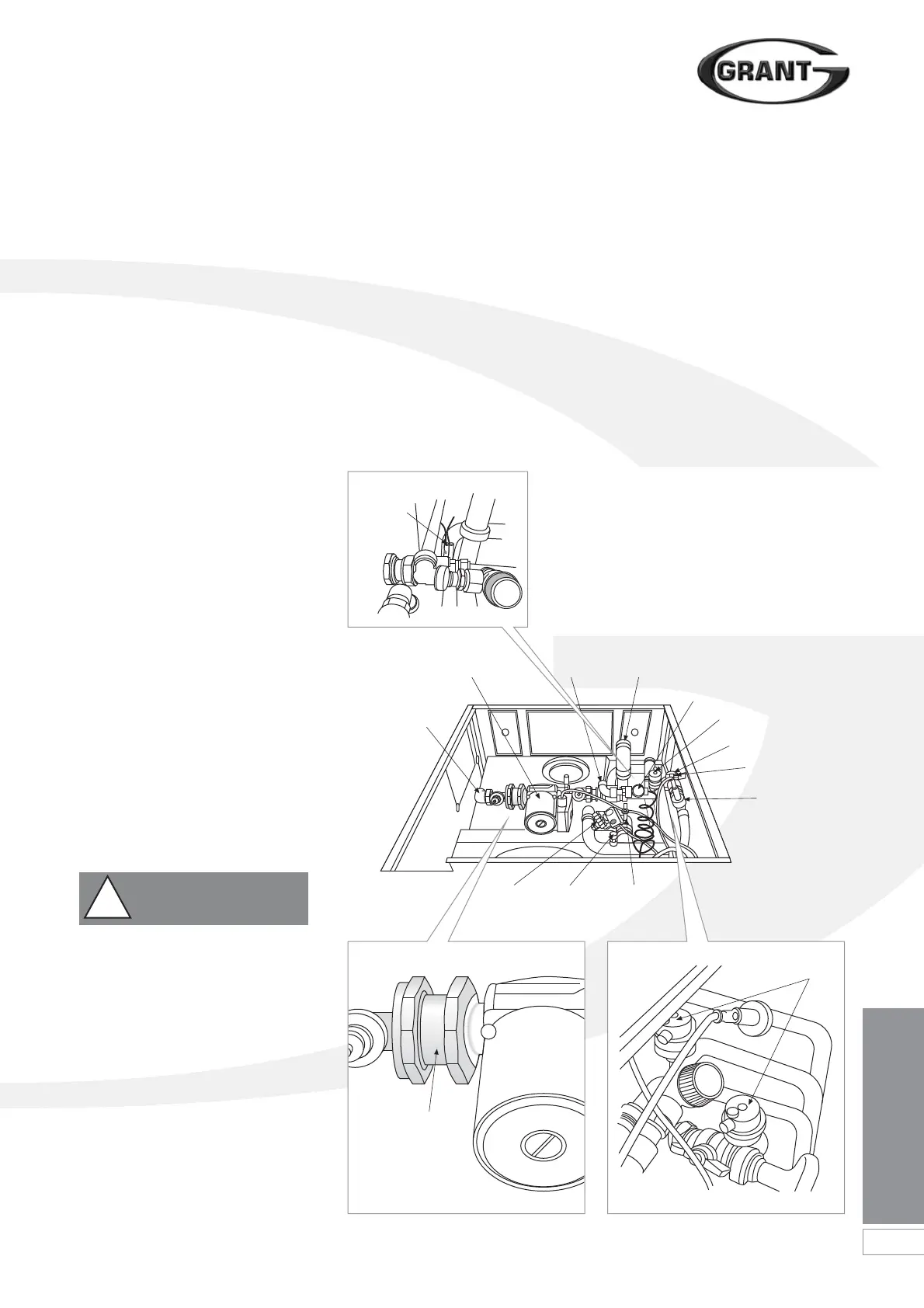

Figure 5-1: Vortex Pro Combi e pipe positions

Heating flow

connection

Heating circulating

pump

Heating

return

Flow switch

Cold water inlet

isolating valve

Cold water inlet

Automatic air vent

Safety valve

Pressure

switch

Manual

air vent

Primary return

isolating valve

Non return

valve

Automatic

air vents

Boiler flow

sensor and

overheat

thermostat

bulb

Safety valve

outlet

Loading...

Loading...