7

Energy Recovery Ventilation System

No. Item Allowance (mm) Inspection method

4

Longer side of the rectangular

duct

+2

0

Measurement by the ruler

5 Dierential of diagonals 3 Measurement by the ruler

6 Evenness 2

Measurement by the feeler

7 Smoothness of welding joints 1

NOTE

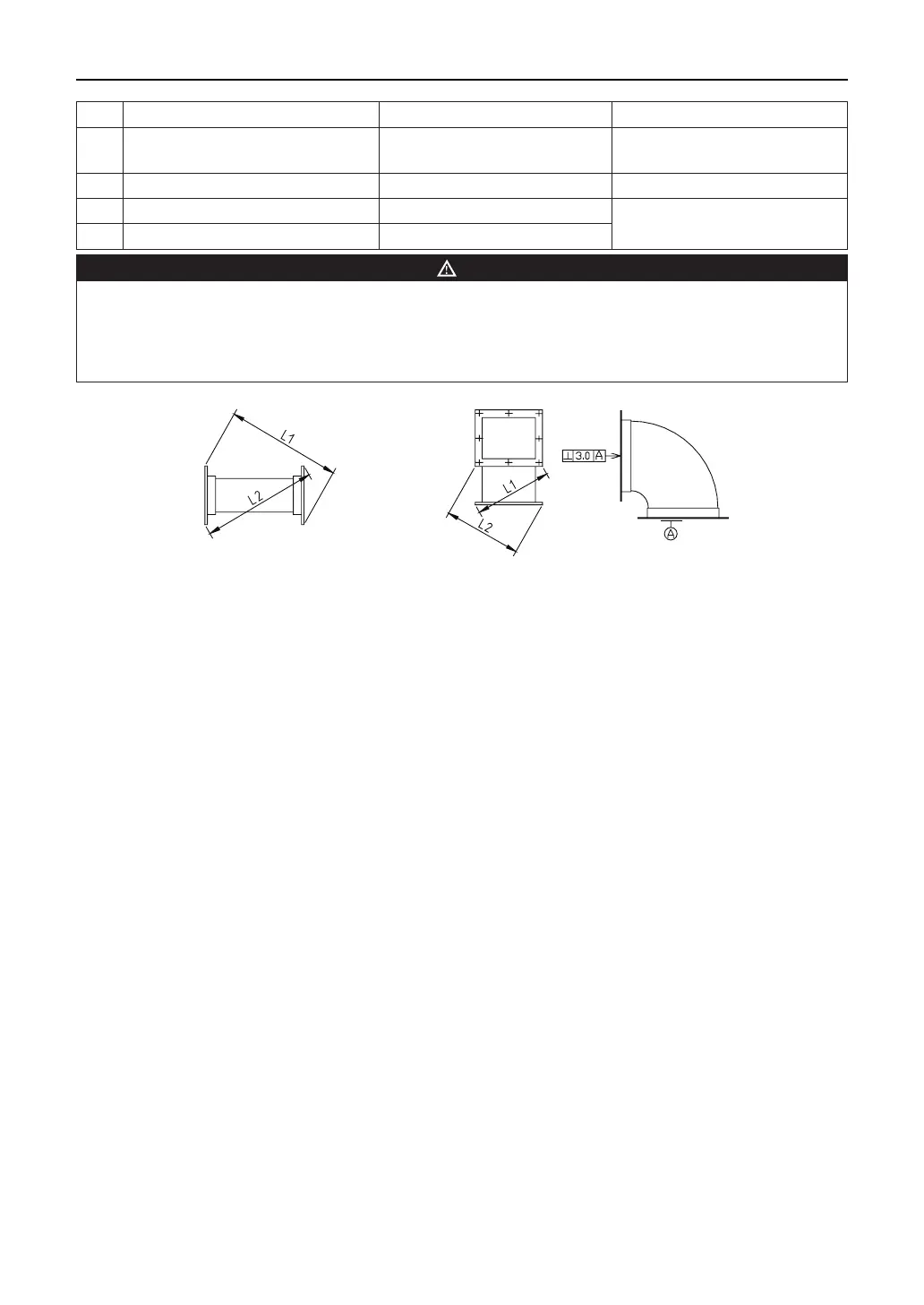

• The absolute value of dierentials of diagonals of the rectangular duct should be |L1-L2|<=3, as shown

in gure 9.

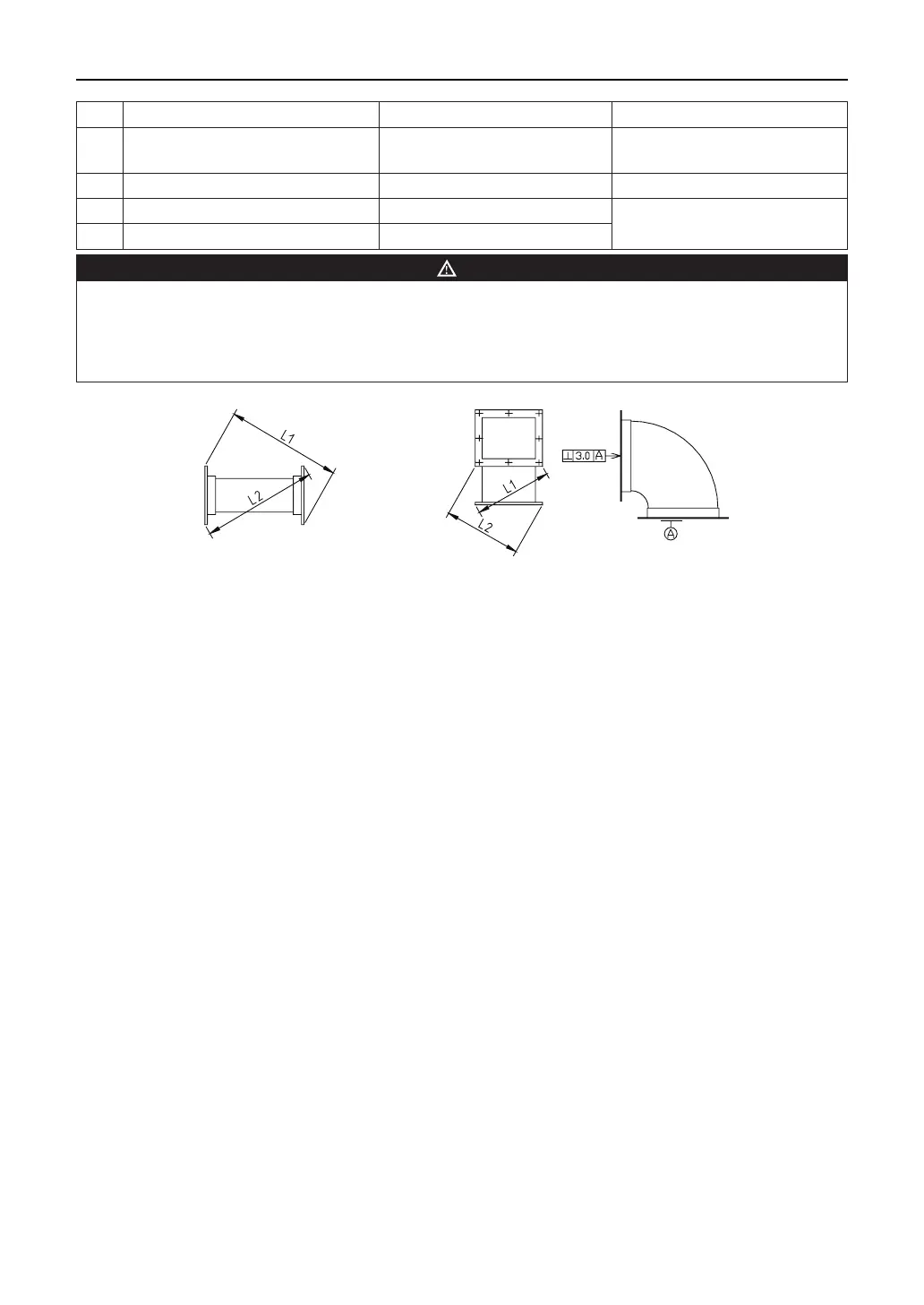

• For anges at two ends of the bend of the rectangular duct, the squareness tolerance should be 3.0

(90

°

), as shown in gure 10.

Figure 9 Figure 10

Note: Installation should be based on the eld-supplied equipment.

2.5 On-site construction requirements

(1) Never lay wires, cables and pipes with toxic, inammable or explosive gas or liquid in the duct.

(2) The dismountable ports and adjustable parts of duct and ttings cannot be installed in the wall or

ceiling.

(3) Foreign matters in or on the duct and ttings should be cleaned before installation.

(4) The construction of bracket or hanger of the duct should accord with the following specications:

1) The build-in tting, setting nail or expansion bolt for bracket or hanger should be placed correctly

and rmly. The inlet part should be free of oil stains and painting.

2) The layout of the bracket or hanger should accord with design specications. If there is no design

specication, following specications will apply.

• Pole bracket or inclined bracket is applicable for horizontal duct against wall or pole and support

bracket for that far from wall or pole. Strip hangers are applicable for ducts with diameters or

lengths of sides less than 400mm.

• Arm bracket or inclined bracket is applicable for vertical duct against wall or pole and anchor ear

bracket for that far from wall or pole .The vertical pipe outside the room or on the roof should be

xed with derrick or dragline.

3) The hanger’s rod should be at and its screw thread should be intact and smooth. Either threaded

connection or welding is suitable for joints of hangers. If the former one is adopted, connecting

thread of either end should be longer than diameter of hanger; moreover, anti-loosing measure

should be made. If the latter one is adopted, lapping joint is applicable and its length should be 6

times longer than diameter of hanger at least at two sides.

4) Holes on the bracket and hanger should be drilled mechanically and never by gas cutting.

Loading...

Loading...