4

Energy Recovery Ventilation System

2 Installation

2.1 Engineering regulation compliance

The user should entrust HVAC engineers for equipment selection and design and invite the qualied

construction organization for on-site construction. Both design and construction should comply with your

state or local regulations and codes. When the unit fails to operate normally owing to improper installation,

service charge will be required.

2.2 Engineering design

The unit inside has two air passages through ducts that help air-to-air exchange. One passage allows

the fresh air outside to enter the room, and the other allows the polluted air (return air) inside the room to

leave. There is resistance to air streams passing through the ducts. Larger resistance reduces the airow.

Duct lengths should be t for the rated static pressure to prevent abnormal sound or damage to motors.

Besides, duct sizes and bends also aect the airow. Therefore, follow the instructions below to avoid

troubles.

(1) In general, each passage does not exceed 15 meters or up to 30 meters. The internal sectional

area depends on the inside air speed (8m/s for the main duct, 5m/s for the branch). If rectangle

ducts are used, the proportion of two neighboring sides will not exceed 4. Air ducts should be

nonammable.

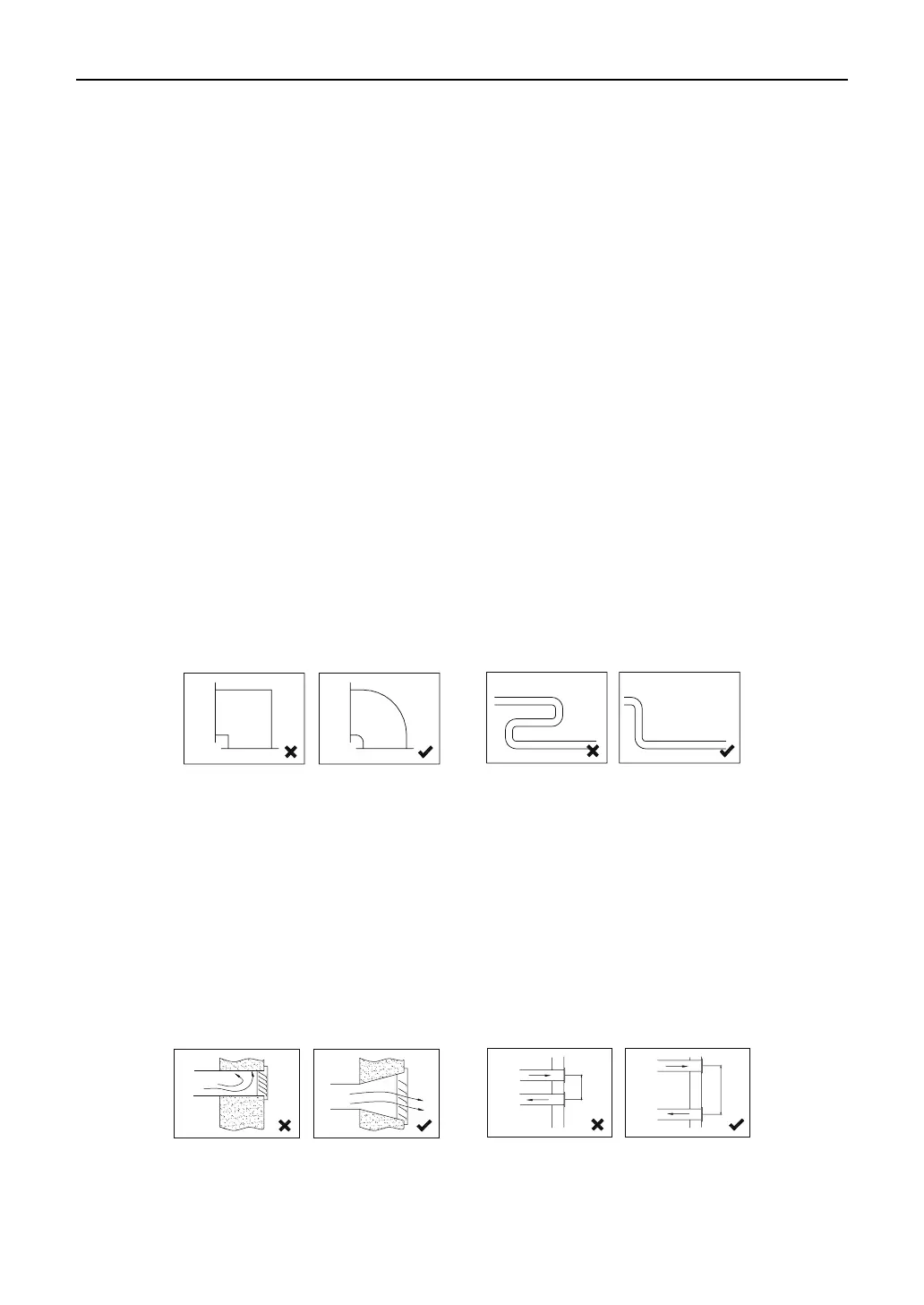

(2) The bends should be kept as few as possible and do not exceed 3 for each passage. The curving

part of the bends should be round-arc, and the straight angle should be avoided, as shown in the

gures below. Note that installation should be based on the eld-supplied equipment.

Figure 2 Bend type Figure 3 Pipe arrangement

(3) The duct wall should be smooth, dustless and pucker-free.

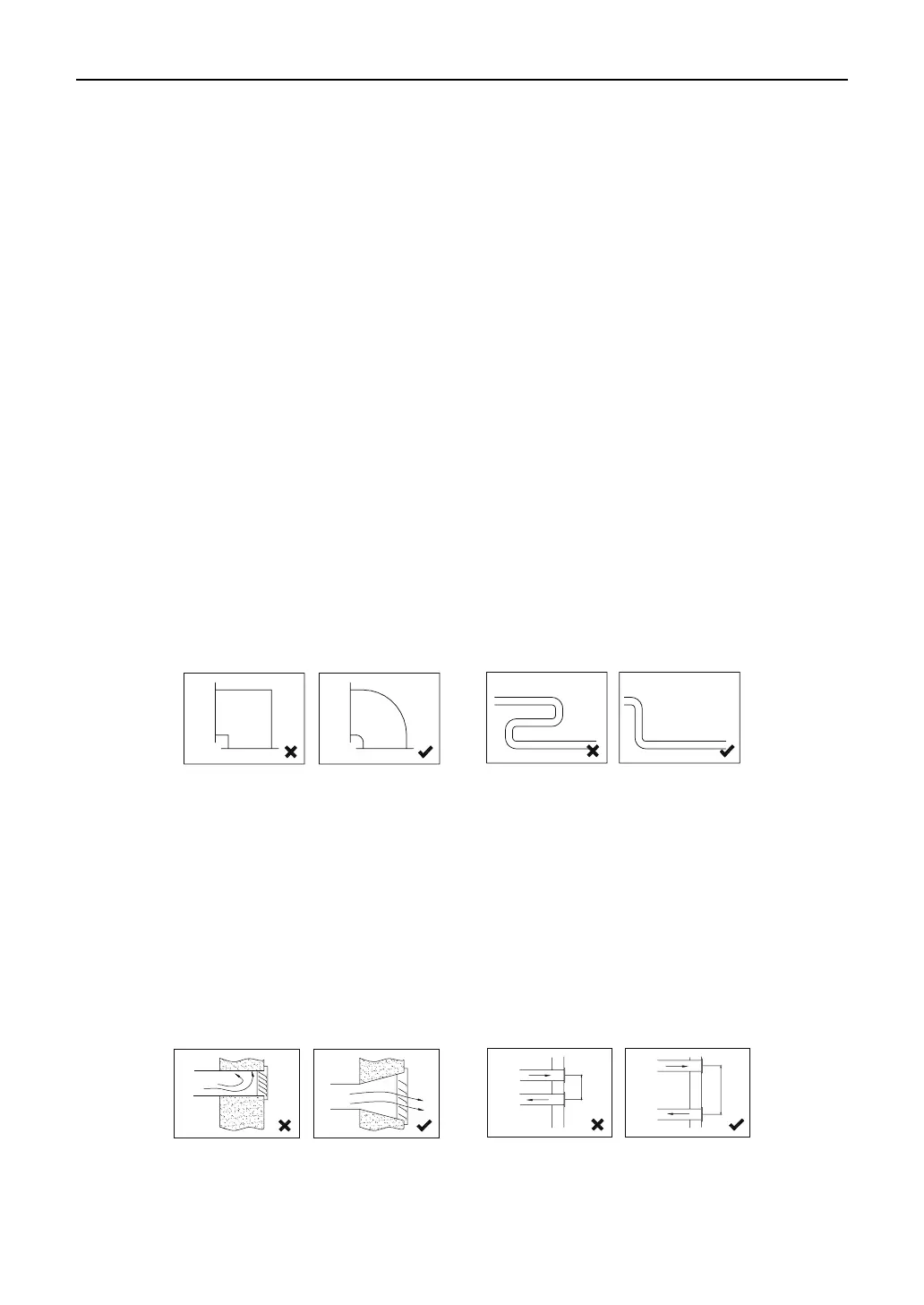

(4) Resistance to the air vents of the room should be kept as less as possible. It is suggested to install

indoor rectangular aluminum alloy diusers or dual-layer grilles (no less than 200×200mm in size).

If a water-proof grille is used for outdoor air vents, its size should be 3 to 4 times the sectional area

of a connected duct, and the blade shape of the grille should facilitate the air ow. See gure 4 to

select diusers and grilles.

(5) In order to prevent discharged air returning back, at least 1000mm should be kept between two air

vents at the outer wall, as shown in the gure 5. Note that installation should be based on the eld-

supplied equipment.

<1000mm

>1000mm

Figure 4 Shape of the air opening Figure 5 Distance between air openings

(6) When it is expected to minimize indoor noise, it is suggested to install a muffler inside the air

passages. Please contact a specialist to select a muffler. Generally, the muffler can reduce the

sound level at vents by 4dB to 6dB.

Loading...

Loading...