6

Energy Recovery Ventilation System

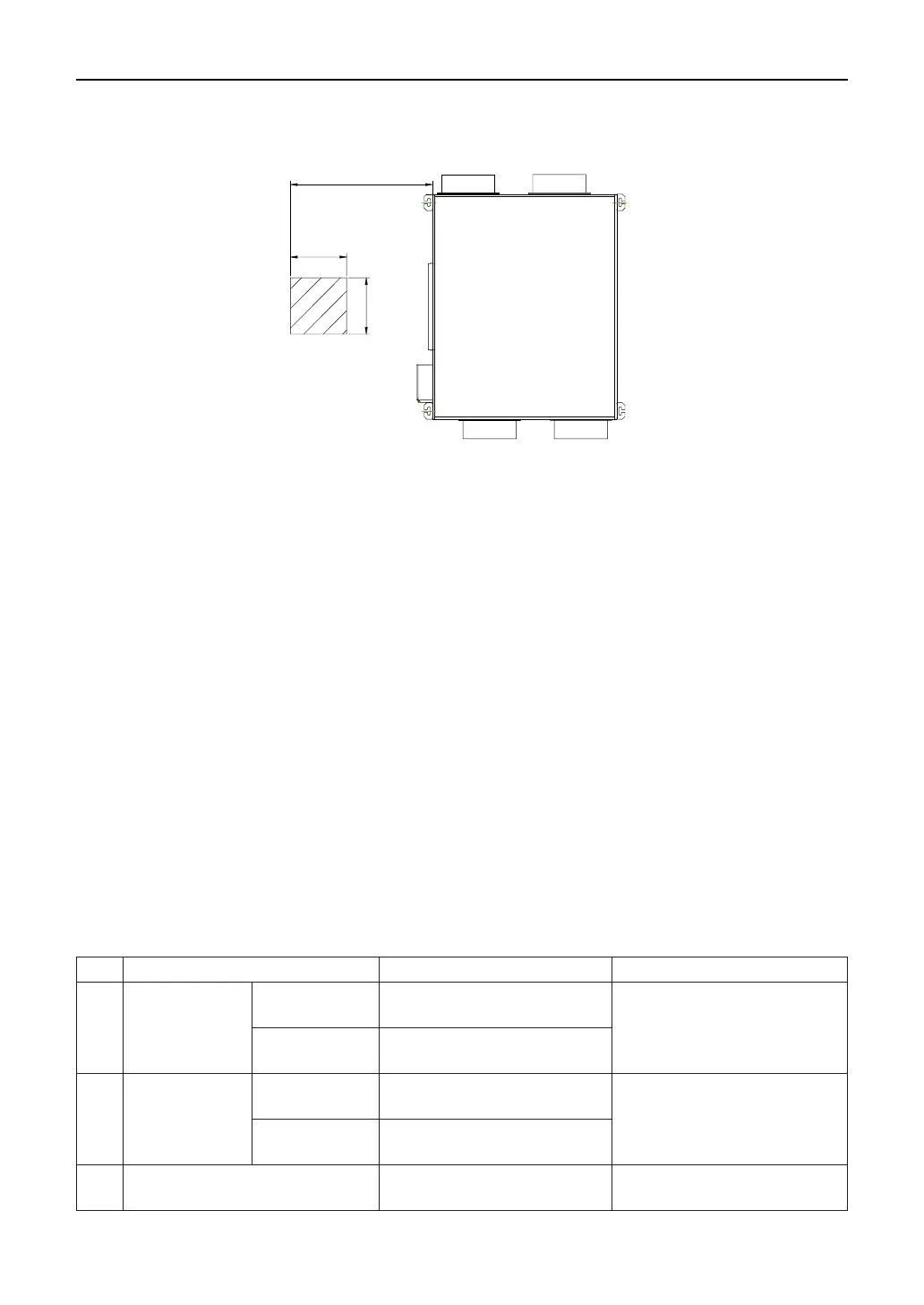

Keep adequate service clearances for convenient maintenance of the lter and heat exchanger. (See

gure 8.)

Access door

Fresh air outlet Return air inlet

Return air outlet

Fresh air inlet

600

600

1000

Figure 8 Service clearances

Note: Service clearances are based on the actual structures and unit design.

2.4 Air ducts and anges

(1) All sheet and sectional materials should be with certicates of qualication.

(2) Thickness of the steel should comply with requirements on the drawing.

(3) There should be no cracks, scars and watermarks on the galvanized steel but crystal pattern.

(4) Size of the duct should comply with design requirements.

(5) Joint of the duct should be airtight, even and have no faults.

(6) For the duct, angles should be straight, round arcs should be even and unevenness should be

within 5mm.

(7) Connection between the duct and the flange should be fastened and flanging width should be

no less than 6mm. Holes spacing of anges should meet design requirements and construction

regulations.

(8) The surface of carbon steel anges should be applied with red anti-rust paint and coating should be

even and closely-packed.

(9) See the table below for allowances for ducts and anges.

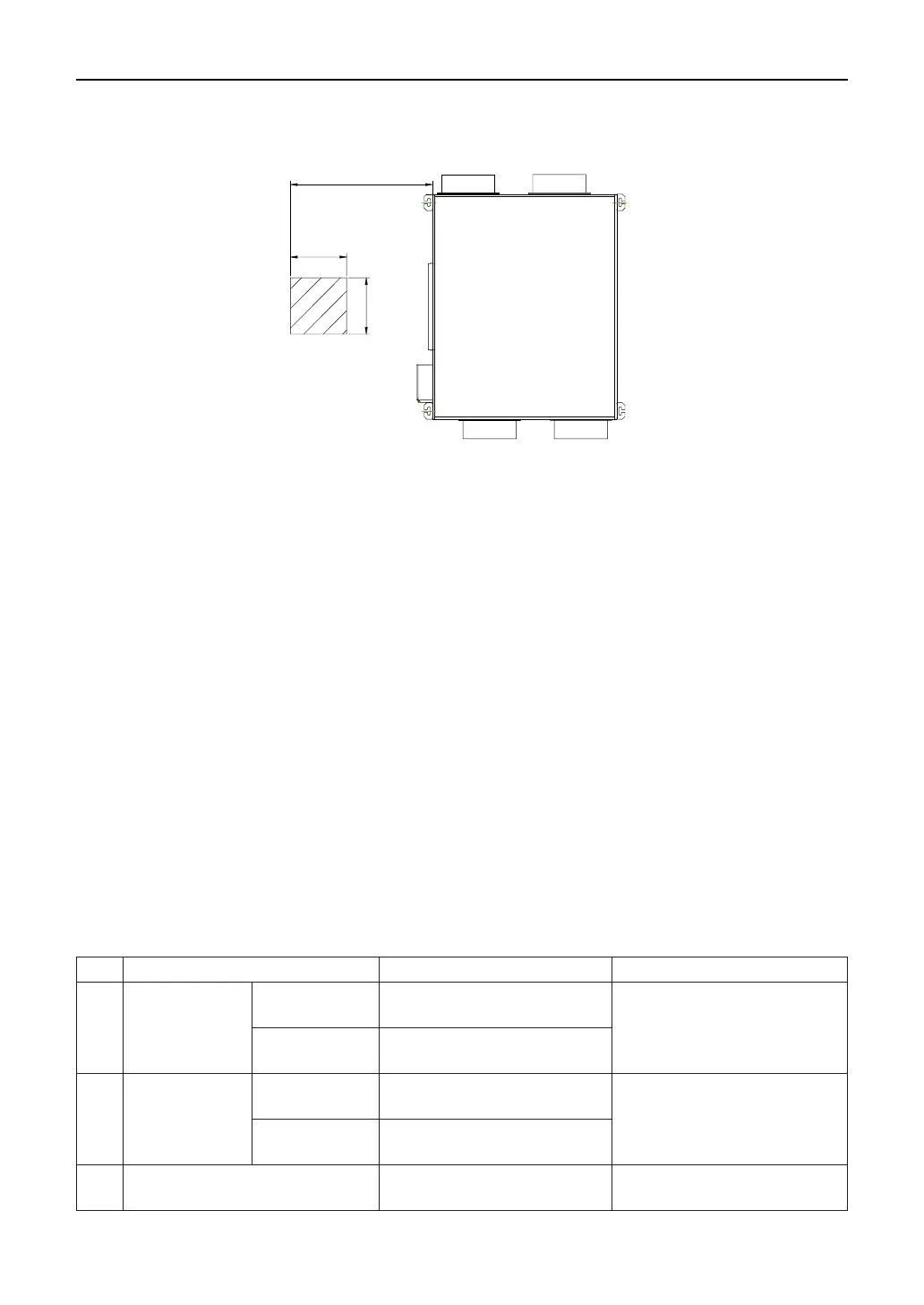

Allowances for ducts and anges

No. Item Allowance (mm) Inspection method

1

OD of the

round duct

φ

<=300mm

0

-1

Measurement by the ruler

φ

>300mm

0

-2

2

Long side of

the rectangular

duct

<=300mm

0

-1

Measurement by the ruler

>300mm

0

-2

3 Diameter of the round ange

+2

0

Measurement by the ruler

Loading...

Loading...