5

Energy Recovery Ventilation System

(7) When an electric heater is installed, it should be interlocked with the ventilator. That is, the electric

heater will work only when the ventilator has been started. Ducts within a distance of 800mm with

the electric heater and ducts which go through a room where there is a re source, they should be

made of non-inammable materials.

(8) The ltering element should be replaced periodically. Therefore, a certain distance should be kept

at one side for maintenance.

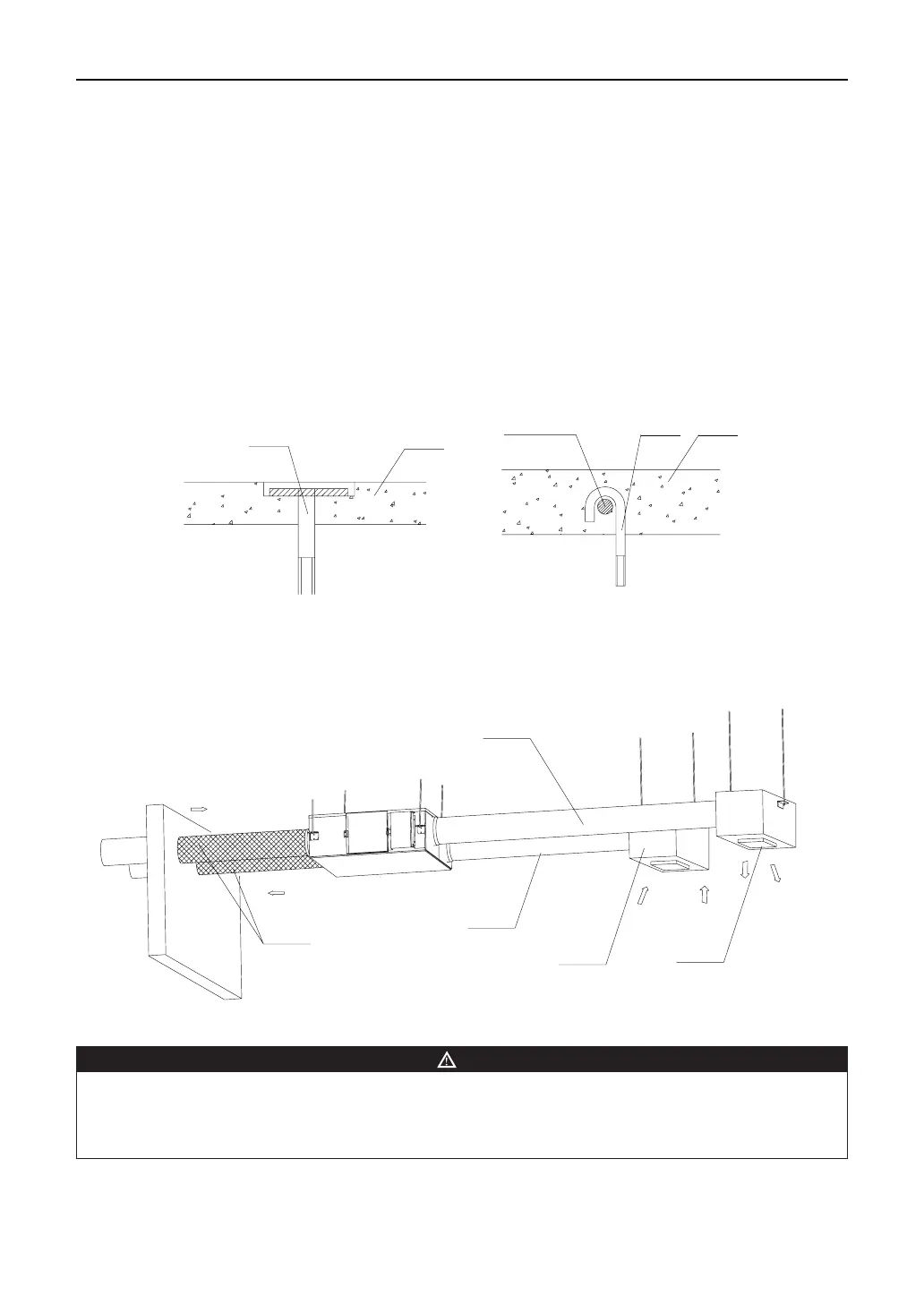

(9) A steel hanger frame should be pre-embedded before installation. Its type and specification

depends on the weight of the ERV to ensure stability. For the retrotting project, drill holes at a

ceiling for the hanger frame, as shown in the gure 6(a). When hole drilling is unavailable, locate

the reinforcing steel inside a concrete ceiling and take it as the hanger frame, as shown in gure

6(b). Note that installation should be based on the eld-supplied equipment.

Reinforcing steel

Hanger frame

Ceiling

Hanger hook Ceiling

Figure 6 (a) Figure 6 (b)

(10) When the ceiling is damaged during installation, it should be repaired before completion of this

project.

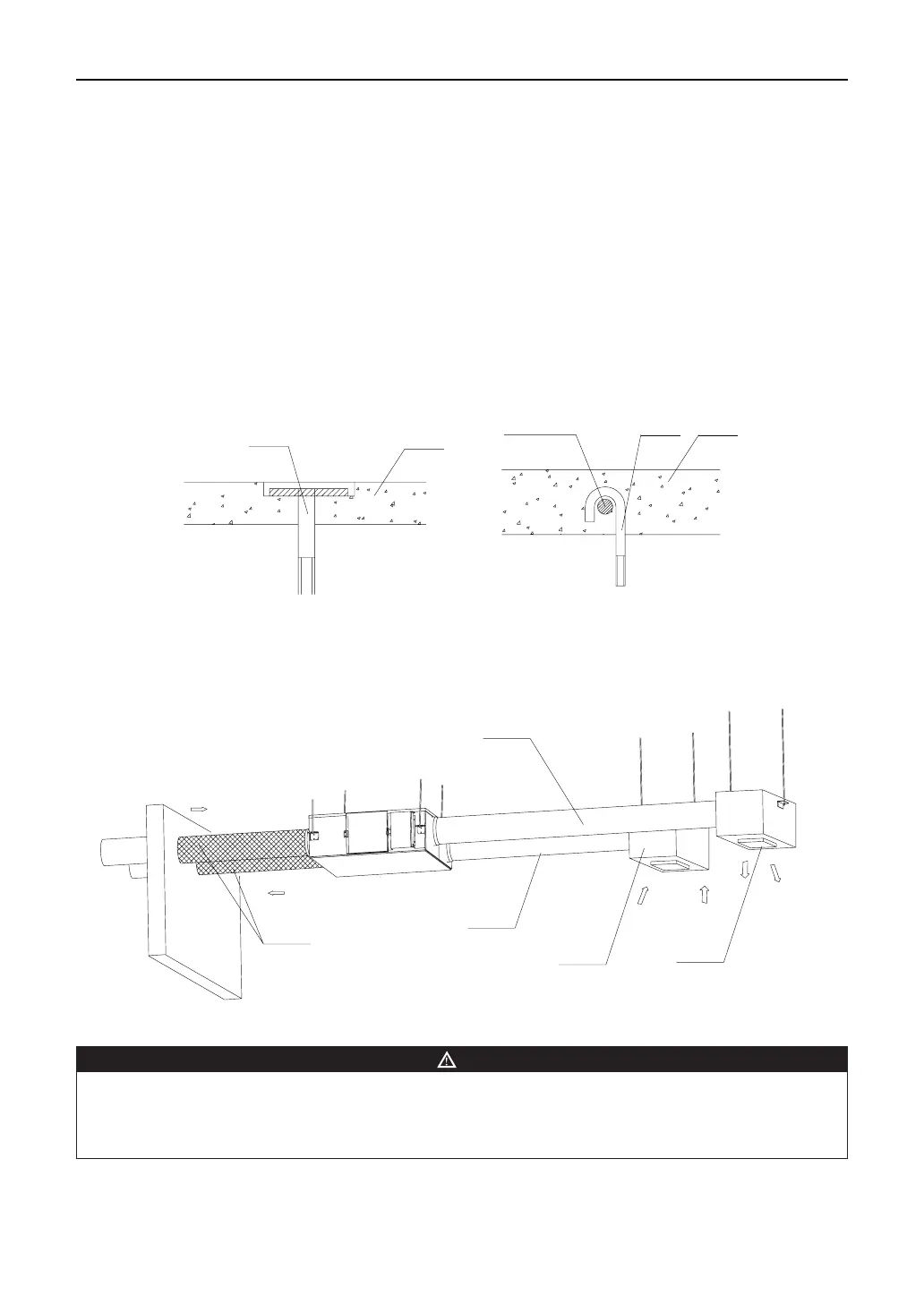

2.3 Installation diagram

Discharge air duct

Fresh air duct

Fresh air inlet

Insulation

Return air outlet

Return air inlet

Fresh air outlet

Return air

Supply ai

r

Figure 7

Note: the installation arrangement is based on the actual structures and unit design.

NOTE

Outdoor ducts connected with the fresh air inlet and polluted air (return air) outlet should be

insulated, so do indoor ducts when temperature and humidity is quite high inside the ceiling. Besides,

the indoor ducts should keep a certain gradient (1/50~1/30) to prevent water entering inside.

Loading...

Loading...