12

Energy Recovery Ventilation System

◆

Trial run

(1) Turn on the unit. Refer to

Owner's Manual

of the controller for more details.

(2) When there is any unusual condition, cut o the power supply immediately for troubleshooting.

◆

Routine maintenance

The air lter must be installed; if not, the heat exchanging core will be covered with feculence and dust

so that its performance will be reduced. If airow volume or discharge air volume is obviously decreased,

the filter should be replaced. Replacement period can be displayed through the controller and can be

changed according to actual conditions in each area. The replacement method is quite simple. That is,

open the access door, take out the old lter, place the new one, and then close the access door.

Remember to cut off the power supply before installation and maintenance to avoid electrocution.

Wiring arrangement should comply with corresponding requirements, otherwise it would lead to

electrocution or re.

5 Troubleshooting

After trial run, the unit can be normally used by the user. If any fault occurs, resolve it rstly by yourself

according to the following table.

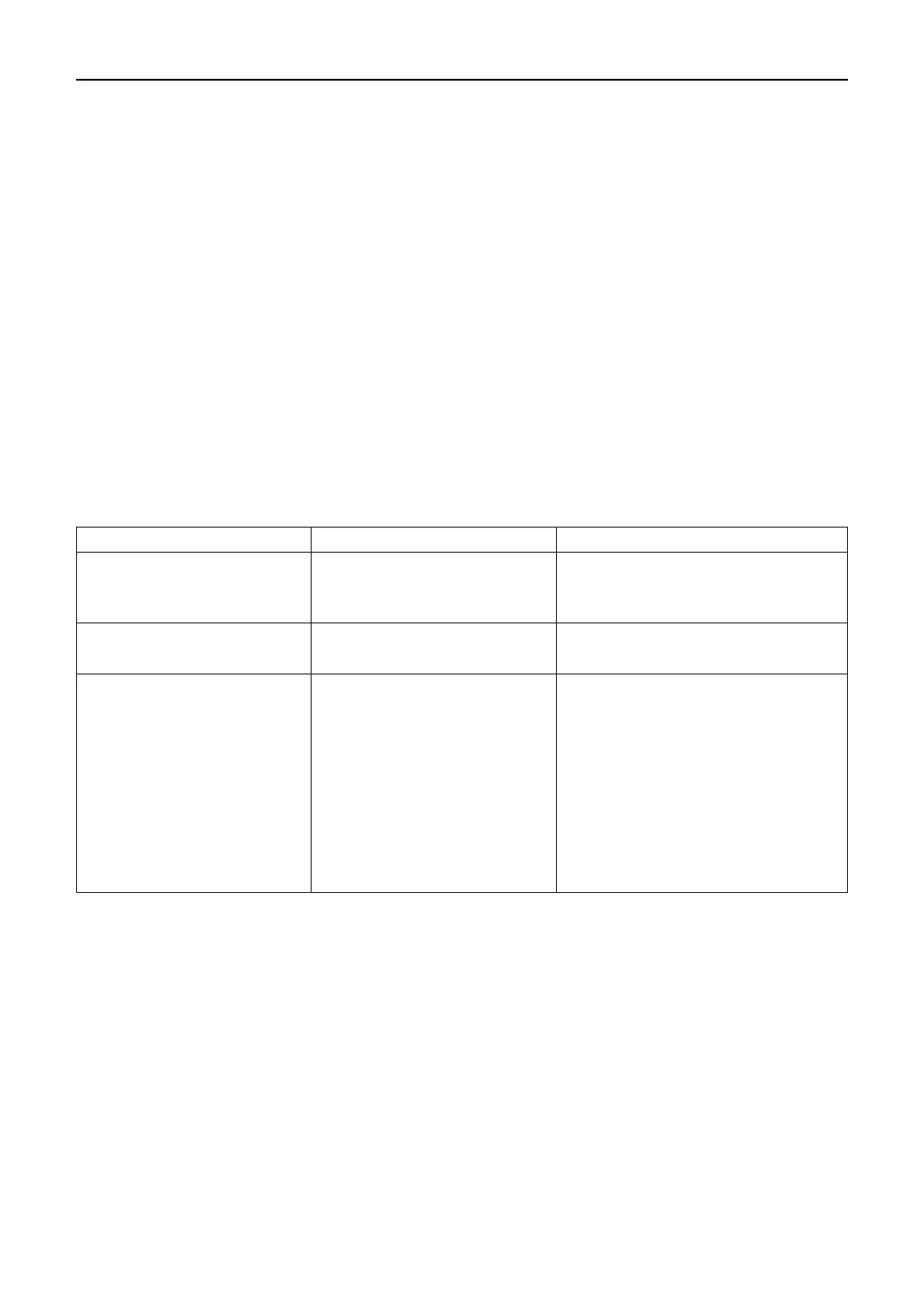

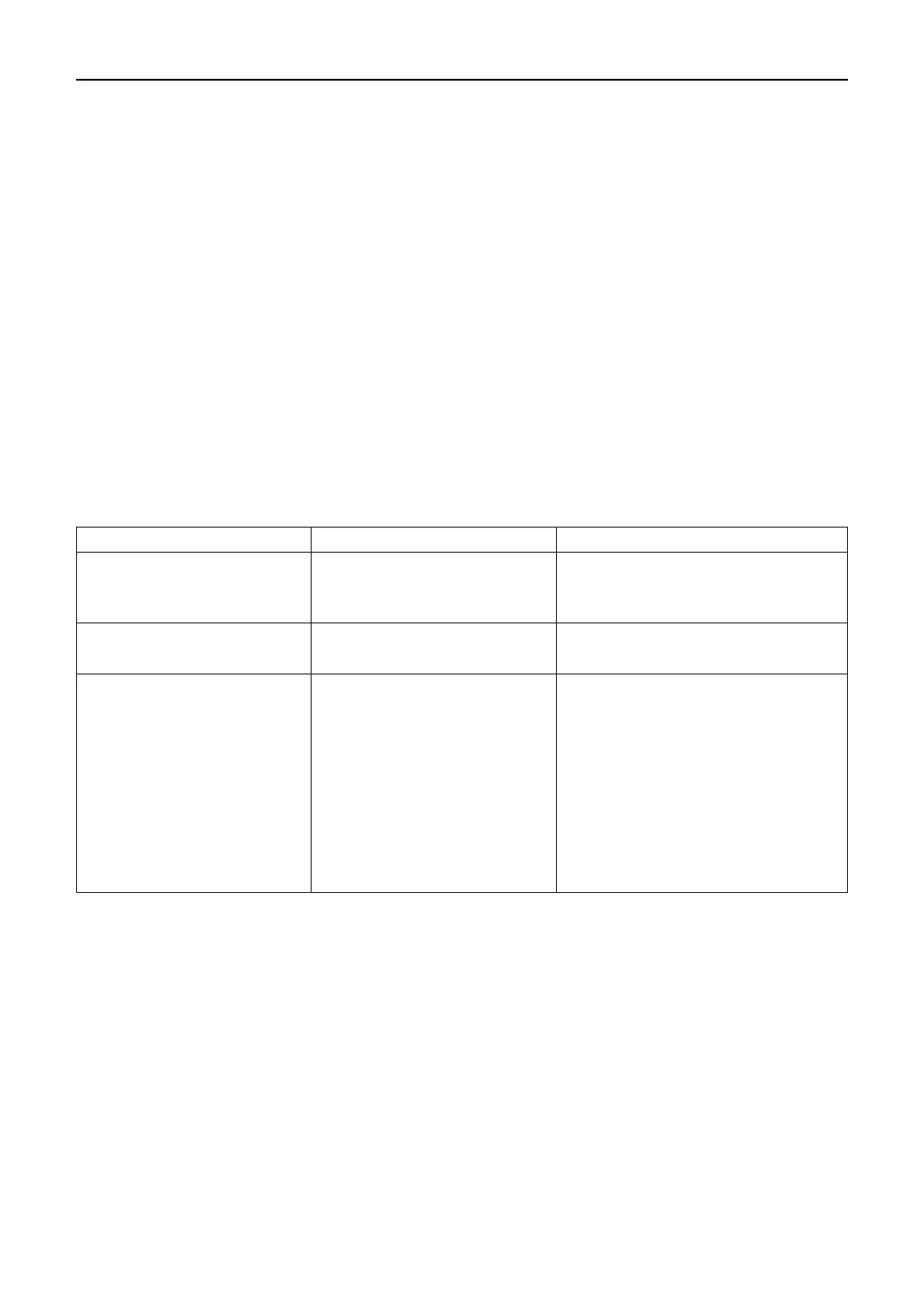

Symptoms Possible causes Recommended action

Airow volume at air outlet/

inlet is obviously decreased

after a period of time.

Too much dust gathers on the

air lter.

Replace or clean the air lter.

Abnormal sound level arises

at air vents.

Installation of the air vent is

loose.

Re-x the air vent.

The system fails to be started.

• Power failure or incorrect

power lines

• Loose transformer terminals at

the main board

• Communication error (E6)

• Damper or relative parts error

(L0)

• Unconnected damper control

at the main board (L0)

• Recover power supply and check for

wiring of the power supply.

• Reconnect the transformer terminal.

• Check for connection between the

controller and the main board.

• Check for the by-pass damper and

the drive.

• Connect it.

Loading...

Loading...