47HARDI

®

NAVIGATOR 550M, 800M, 1000M CENTRIFUGAL OPERATOR'S MANUAL

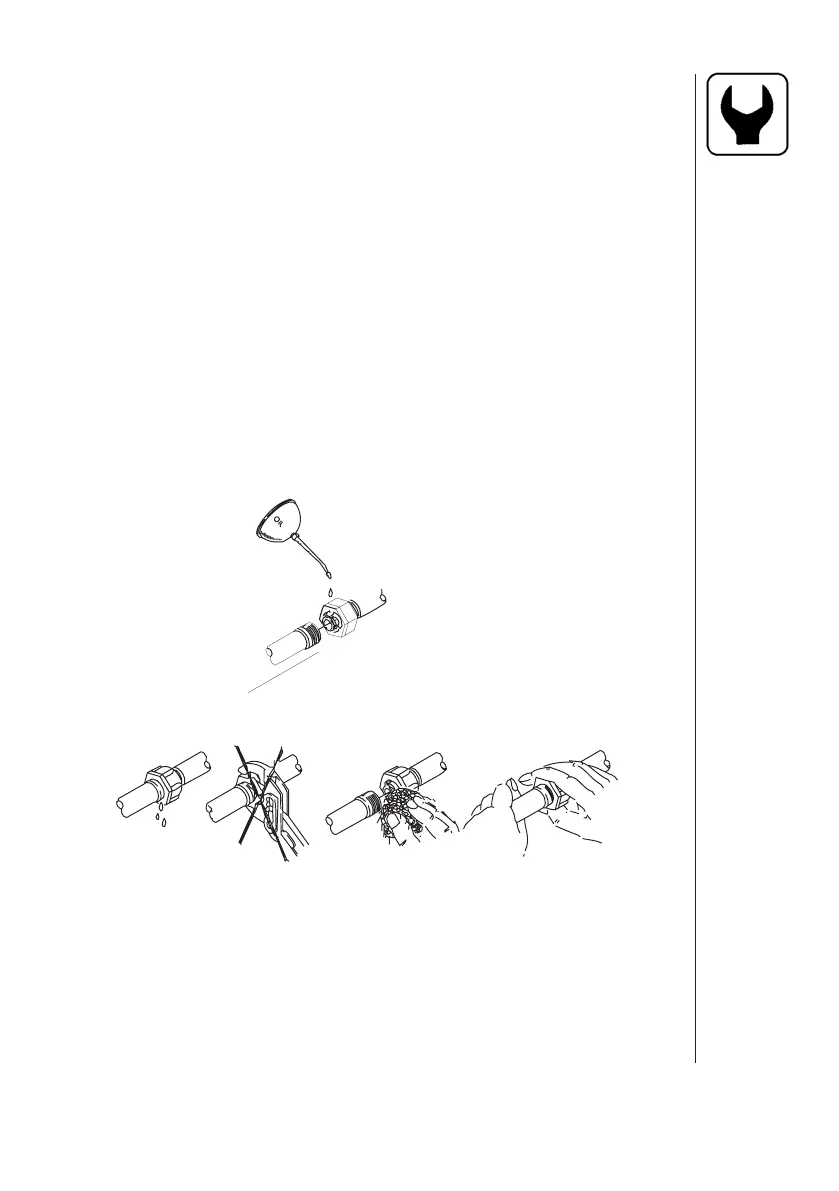

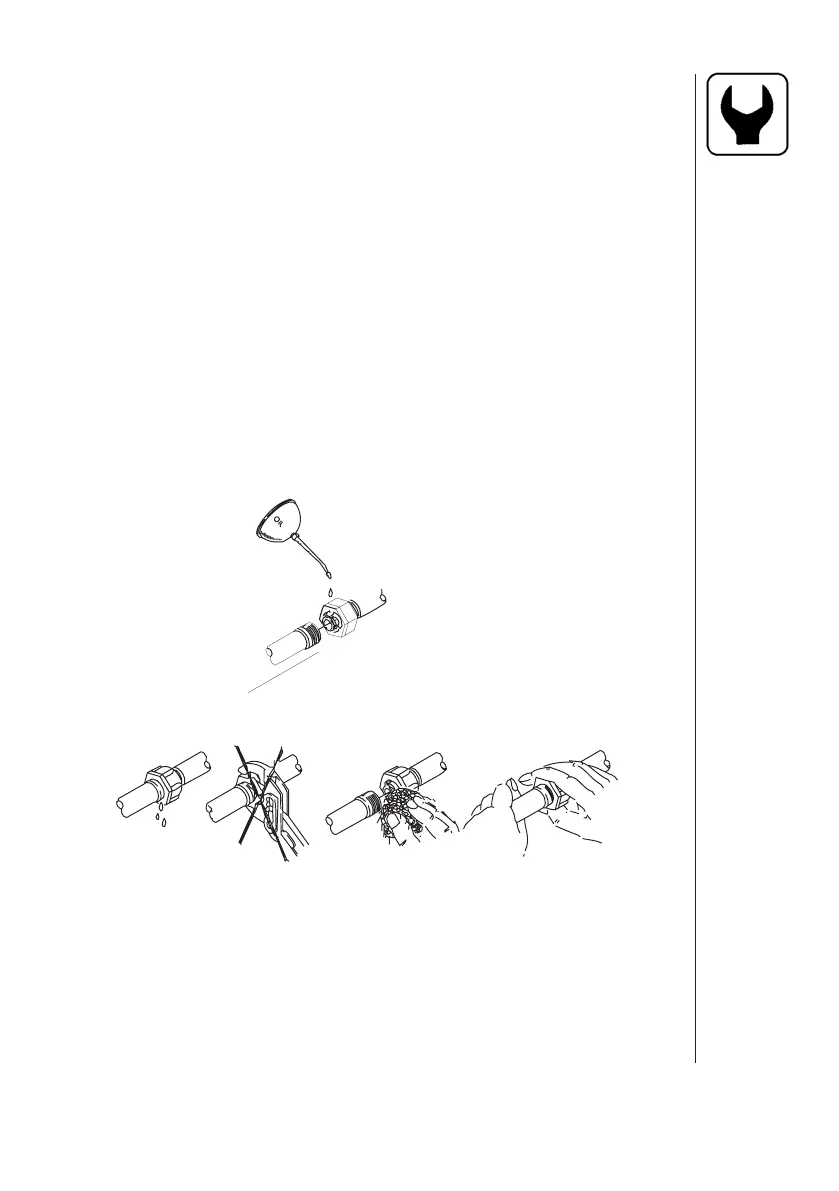

5.6 Nozzle Tubes And Fittings

Poor seals are usually caused by;

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten (Fig. 23). Disassemble,

check condition and position of O-ring or gasket, clean, lubricate and

reassemble.

For radial type seals (O-ring)(Fig.23) hand tighten only, do not use pli-

ers.

The O-rings need to be lubricated ALL THE WAY AROUND before fi tting

on to the nozzle tube.

Fig. 23

HARDI

®

recommends using a vegetable based oil to prolong the life of

the O-ring.

Loading...

Loading...