13

SECTION 3. INSTALLATION

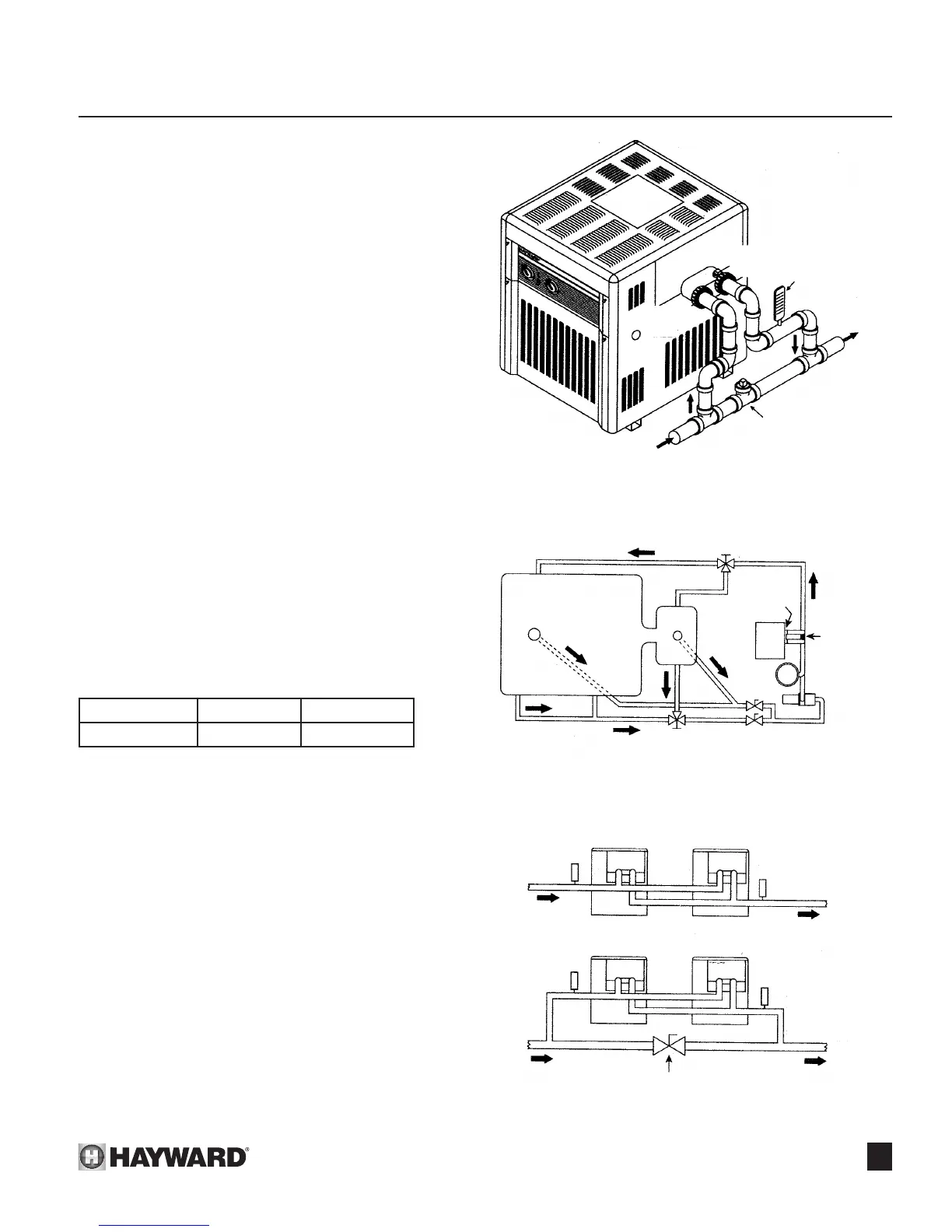

Plumbing connections:

1. The H-Series heater is equipped with CPVC SCH-80

anged pipe nipples, union nuts, neoprene O-rings

for use with 2” pipe connections. Figure 22 shows the

method for installing these parts on the front header.

! NOTE: Assemble these parts to heater prior to plumb-

ing. Tighten union nuts securely before gluing ttings to

ends of pipe nipples.

2. The CPVC SCH-80 anged pipe nipples must be

installed on the heater inlet and outlet without modica-

tion. CPVC SCH-80 plastic has an ASTM rating of F441

and is NSF approved. The opposite ends of the pipe

nipples should be attached to the ltration system as

particular installation dictates.

3. Pipe, ttings, valves and any other element of the lter

system may be made of plastic materials, if acceptable

by the authority having jurisdiction. 1 1/2” plastic pipe if

used, will slide directly into the anged pipe ends.

4. Heat sinks (heat traps), reman switches and check

valves are not necessary on the H-Series heaters.

However, if there is any chance of “back-siphoning” of

hot water when the pump stops running, it is suggested

that a check valve be used on the heater inlet pipe.

5. The vari-o by-pass that is built into the front header

will maintain proper ow through the heat exchanger

if the ow rate is within the range for the heater. See

Figure 23.

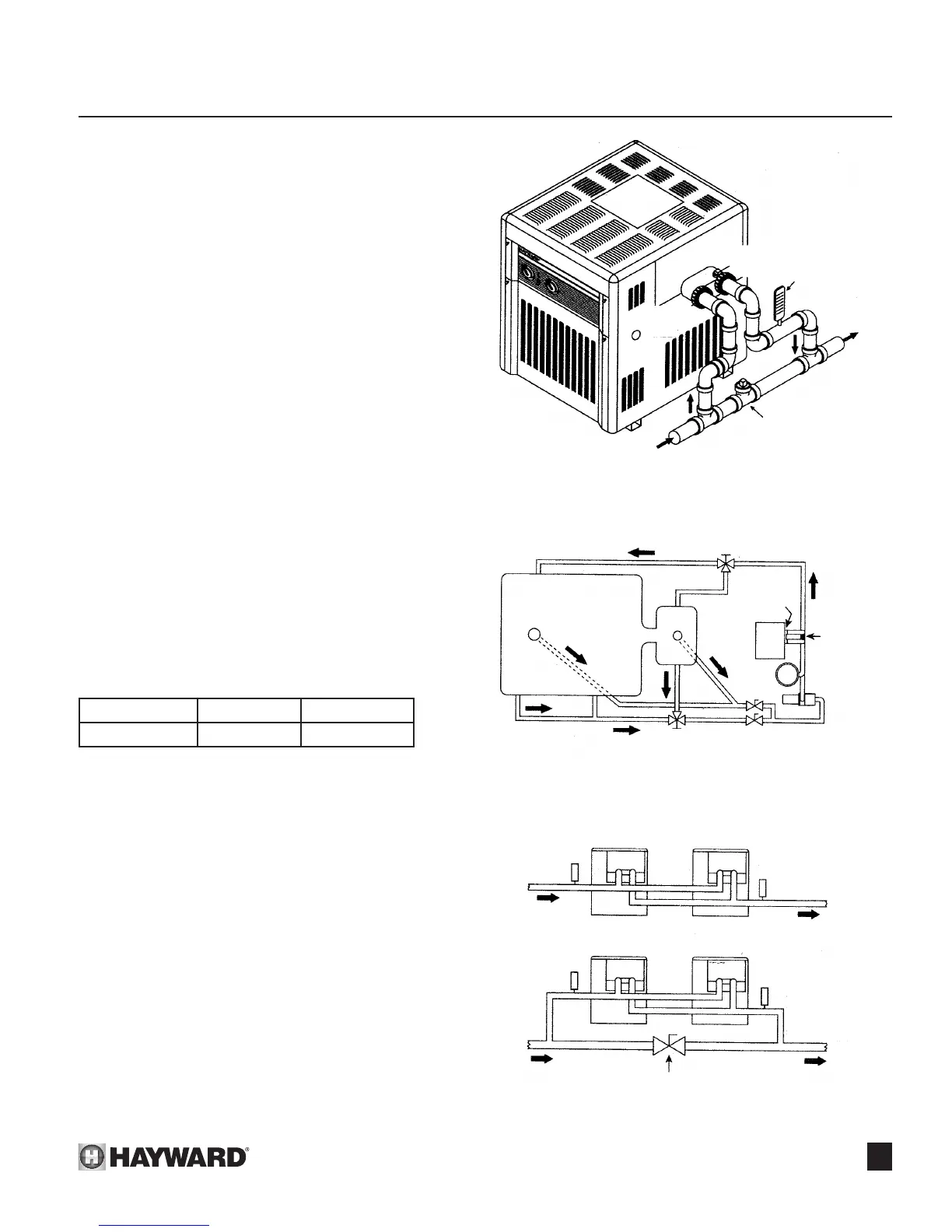

6. If the normal pump and lter system ow rate exceeds

125 gpm then a manual by-pass valve, as shown in

Figure 24, must be installed as follows: Install a ow

meter on the outlet line of the heater. Adjust the manual

by-pass valve until the ow rate is within the rates re-

quired for the heater. Once the valve is set, the position

should be noted and the valve handle removed to avoid

further adjustment.

7. Figure 25 shows a typical pool piping diagram and lay-

out for pool equipment. Figure 26 shows multiple heater

usage for very large pools with and without an external

by-pass (balancing) valve.

Figure 23

Figure 24: Manual By-pass Valve

Figure 25: Typical Plumbing To Pool

Figure 26: Multiple Heater Hookups

RECOMMENDED FLOW RATE IN GPM

Model Minimum Maximum

H150-H400 25 125

VALVE

FLOW METER

FROM PUMP

AND FILTER

CONNECTION

TO HEATER

OUTLET

RETURN TO

POOL/SPA

CONNECTION

TO HEATER

INTLET

3-WAY VALVE

TO POOL

HEATER

FILTER

PUMP

FROM

POOL

MAIN

DRAIN

3-WAY

VALVE

RELIEF

VALVE

OPTION

POOL

SPA

MANUAL

BY-PASS

VALVE

(if necessary)

BALANCING VALVES

FOR SKIMMER

AND DRAIN

THERMOMETER

THERMOMETER

THERMOMETER

ADJUST

BALANCING VALVE

TO OBTAIN A

20ºF DIFFERENTIAL

ACROSS

THERMOMETERS

THERMOMETER

BALANCING VALVE

TO POOL

TO POOL

FROM FILTER

FROM FILTER

2”

2”

2”

2”

Loading...

Loading...