Heating coil pipes for the indoor unit

Item Connection

~500 mm To connect to the 3-way valve heating coil inlet connection.

~400 mm To connect to the T-branch heating coil outlet connection.

Heating coil pipes for the DHW tank accessory

Item Connection

(1")

(x2)

360 mm

(1")

One pipe to connect to the heating coil inlet connection of the tank

accessory.

The other one to connect to the heating coil outlet connection of the tank

accessory.

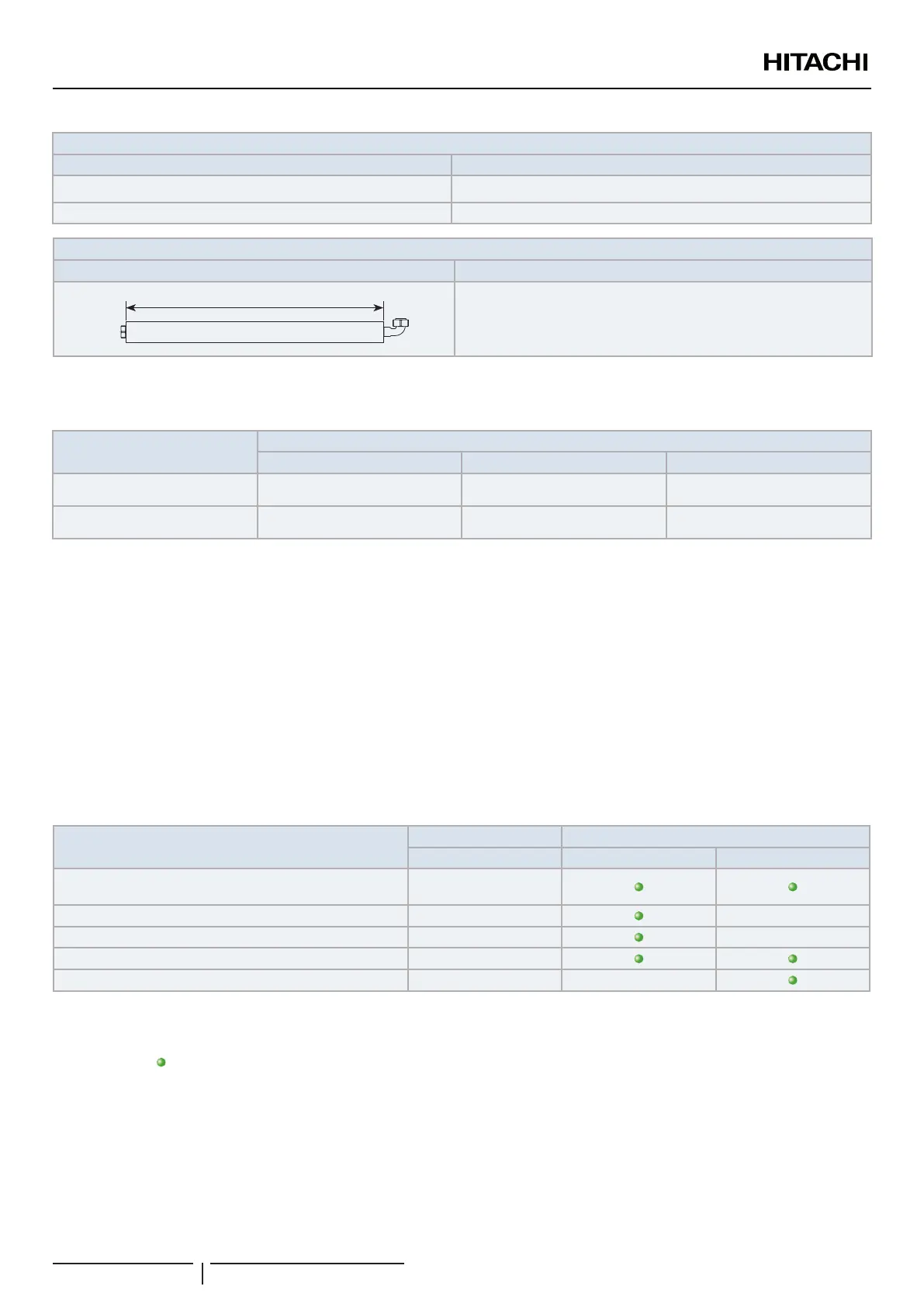

YUTAKI M

(inches)

Model

Space heating pipes connection

Inlet connection Outlet connection Shut-off valves

3.0HP G 1” (female) G 1” (female)

G 1” (male) -

G 1” (male)

(4.0-6.0)HP G 1-1/4” (female) G 1-1/4” (female)

G 1-1/4” (male) -

G 1-1/4” (male)

6.1.4 Water quality (Preliminary information)

! CAUTION

• Water quality must be according to EU council directive 98/83 EC.

• Water should be subjected to ltration or to a softening treatment with chemicals before application as treated water.

• It is also necessary to analyse the quality of water by checking pH, electrical conductivity, ammonia ion content, sulphur content, and others. Should

the results of the analysis be not good, the use of industrial water would be recommended.

• No antifreeze agent shall be added to the water circuit.

• To avoid deposits of scale on the heat exchangers surface it is mandatory to ensure a high water quality with low levels of CaCO

3

.

Recommendations for the DHW circuit

The following is the recommended standard water quality.

Item

DHW space Tendency

(1)

Water supplied

(3)

Corrosion Deposits of scales

Electrical Conductivity (mS/m) (25°C)

{µS/cm} (25 °C)

(2)

100~2000

Chlorine Ion (mg CI¯/I) max 250

Sulphate (mg/l) max 250

Combination of chloride and sulphate (mg/l) max 300

Total Hardness (mg CaCO

3

/I) 60~150

? NOTE

• (1): The mark “ ” in the table means the factor concerned with the tendency of corrosion or deposits of scales.

• (2): The value shown in “{}” are for reference only according to the former unit.

• (3): Water range will be according s/UNE 112076:2004 IN.

6.1.5 Water ow control

YUTAKI pumps can estimate the water ow by electronic calculation. Therefore, there is no need to install a water ow switch with

the new YUTAKI pumps.

However, if a secondary pump is installed or glycol is used (in the case of YUTAKI M), it is necessary to install a water ow control,

as the electronic calculation may be affected.

REFRIGERANT AND WATER PIPING

PMML0335A rev.1 - 04/2016

90

Loading...

Loading...